Continuous Inkjet Printers / Case Coder

Coding on Paper Products

A challenge with coding and marking on paper products is maintaining legibility over time, as paper can wear and be affected by environmental factors that cause markings to fade or smudge.

The MK-G Series of continuous inkjet printers (CIJs) are effective and reliable coding solutions for paper products in the pharmaceutical, packaging, and consumer product industries.

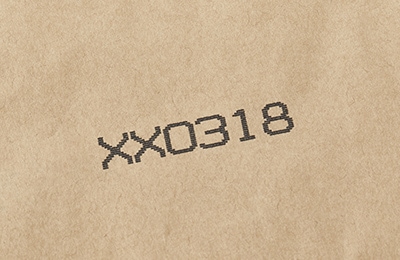

Lot/Date Coding on Paper Products

Effectively trace product origin, manage inventory, ensure the quality of final products, and comply with all necessary regulatory standards with KEYENCE continuous inkjet printers. Whether for the identification of production batches or date information, our MK-G Series of CIJs provides durable and reliable coding on the following paper products.

- Cartons

- Cardboard boxes

- Paper tubes

- Corrugated cardboard

- Paperboard

Cardboard boxes

Paper bags

Cartons

Paper packaging

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Paper Products

Surface Conditions

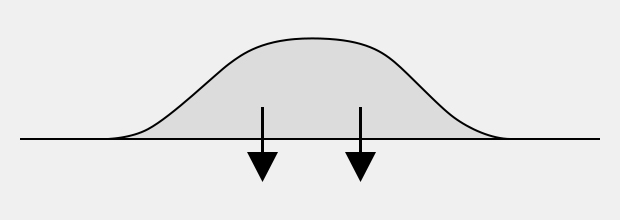

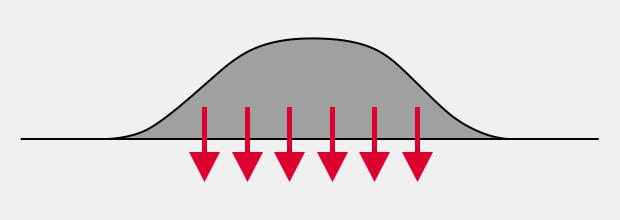

Uneven and coated paper surfaces can make print adhesion challenging. Our MK-G Series CIJs support different inks that are suitable for various paper types.

Reliable adhesion to all materials:

Standard ink

Strong adhesve ink

Standard adhesive strength

Strong adhesive strength

Line Speed

Traditional coding systems struggle with high-speed lot/date coding on paper products. Our industrial inkjet printers offer rapid, accurate marking with advanced features for reliability.

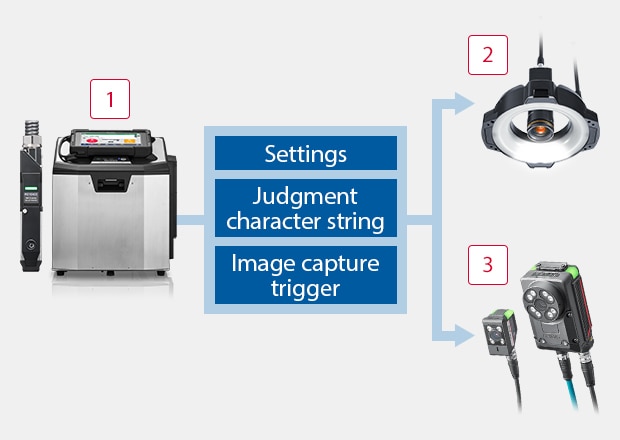

Easily link to a print inspection device with just a LAN cable

Coding Durability

Marked and coded data fading can lead to quality and traceability issues. Our CIJ printers print durable codes on multiple surfaces.

-

1Continuous Inkjet Printer MK-G Series

-

2Intuitive Vision System CV-X Series

-

3Vision Sensor with Built-in AI IV4 Series

Maintenance Costs

Coding solutions requiring skilled labor for maintenance mean high system maintenance costs. Our MK-G Series self-troubleshoots for errors and features a one-touch part replacement function, freeing up skilled technicians for other essential tasks.

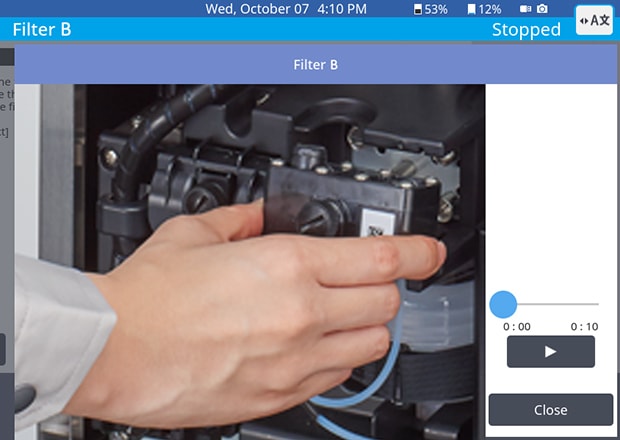

Simply follow the instructional video for error-free replacement.

Access helpful component replacement instructional videos

Replacement instructional videos:

When replacing a component, simply read the barcode or 2D code on the component to watch a helpful instructional video. These easy-to-follow videos make replacement simple even for beginners.

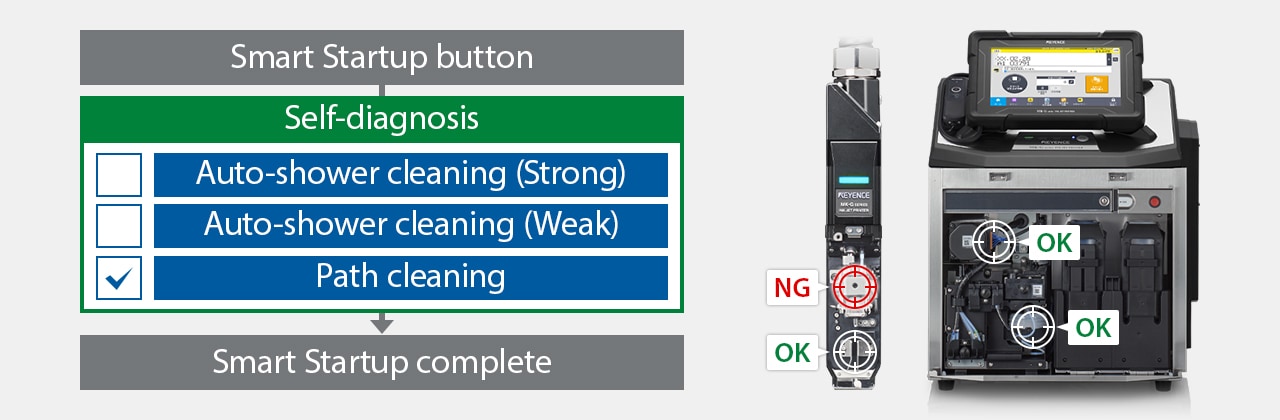

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

Discover more about this product.

Click here to book your demo.

CIJ for Paper Products

Paper is a material of choice for packaging in the pharmaceutical and consumer products industries. We offer our MK-G Series continuous inkjet printers for coding on paper products in these industries. Ensuring the legibility and accuracy of coded information and printed data helps manufacturers in documentation, traceability, and compliance efforts. Use our CIJ for the pharmaceutical and consumer products industry to complete lot/date coding on paper products.

Curious about our pricing?

Click here to find out more.

FAQs about Marking and Coding in the Paper Industry

What Is the Importance of Coding and Marking on Paper Products in Manufacturing?

Marking and coding paper products used for packaging materials helps manufacturers identify and trace finished goods while ensuring compliance with regulatory standards.

How Does Lot/Date Coding on Paper Products Ensure Traceability and Compliance?

During product recalls, coded date/lot information makes it easy to identify and isolate affected products. Regulatory compliance requires the proper identification of products delivered to the market.

What Factors Should Be Considered When Selecting a CIJ Printer for Coding on Paper Products?

Speed, print quality, ink adhesion, costs, ease of maintenance, and integration with the product line are important factors when considering any continuous inkjet printer.

How Does MK-G Series Technology Ensure Durable and Precise Coding on Paper Products?

KEYENCE’s MK-G Series technology supports different ink models and comes with features like an easy to use interface and automatic troubleshooting.

How Does MK-G Series Ensure High-Quality, Consistent Coding on Various Types of Paper Products?

The MK-G Series comes with features, such as automatic ink particle optimization to help regulate ink viscosity irrespective of temperature or other environmental conditions.

![Packaging Technology Introduction [Packaging Machine Edition]](/img/asset/AS_82098_L.jpg)