Continuous Inkjet Printers / Case Coder

Coding on Nutraceutical Packaging

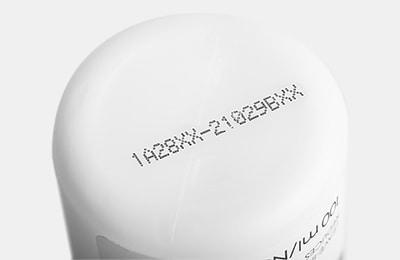

Nutraceuticals often come in smaller packaging due to their concentrated nature, leaving less space for essential information.

The KEYENCE MK-G Series of continuous inkjet printers (CIJs) helps pharmaceutical product manufacturers efficiently code lot/date information on nutraceuticals. Use our CIJs for coding on nutraceutical packaging to ensure the quality of finished products, traceability, and compliance with regulatory standards.

Lot/Date Coding and Marking on Nutraceutical Packaging

Accurate coding of date and other product identifying data on the packaging of nutraceuticals is crucial to ensuring consumer information, documentation, traceability, and compliance. Our MK-G Series of CIJ offers a low-maintenance and efficient coding solution for nutraceutical packaging materials, including:

- Cubes

- Bottles

- Pouches

- Sachets

Glass bottles

Plastic containers

Pauches

Form-filled packages

Heat-sealed packages

Cartons

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Nutraceutical Packaging

Packaging Variability

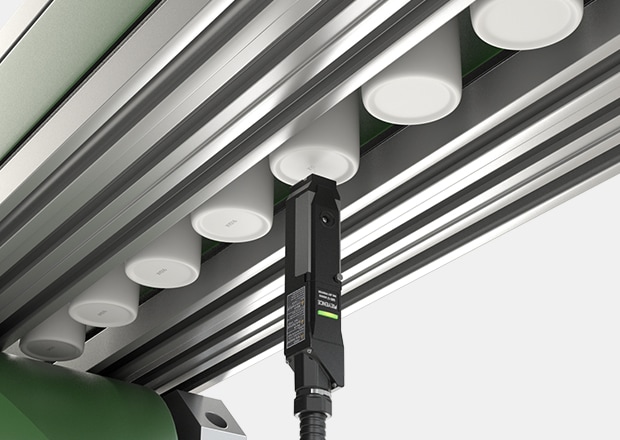

Nutraceuticals require different packaging. Our MK-G Series printers can be installed on a wide range of production lines and code on different nutraceutical packaging.

Installation example

Installation example

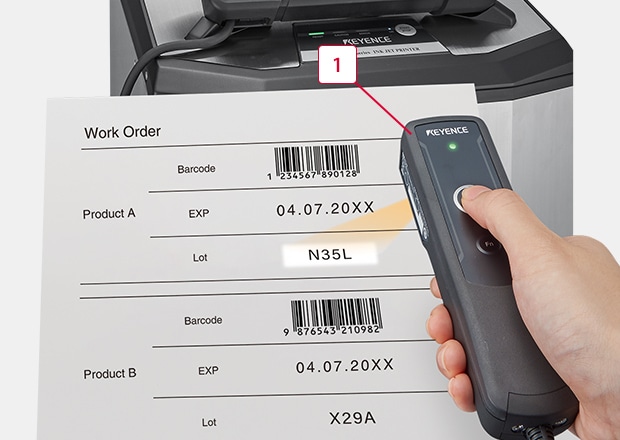

Batch Sizes

Registering images using the camera

Nutraceutical manufacturers producing in small batches find frequent product changeovers challenging. Our MK-G Series comes with features like Smart Program change that take the guesswork out of switching over to different print recipes.

-

1Operation assist camera

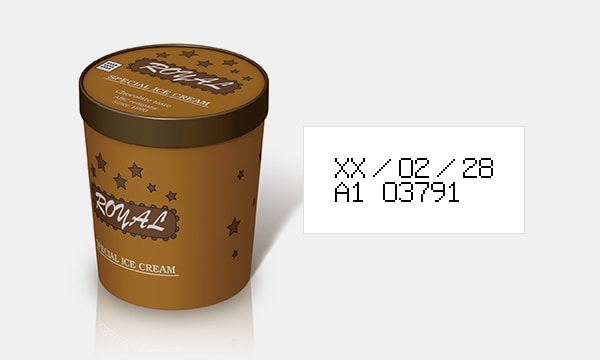

Ice cream

Cheese (cup container)

Print Quality

Ink smudging and durability are challenges in nutraceutical coding. MK-G Series printers support different ink models and regulate ink viscosity despite temperature and environmental conditions.

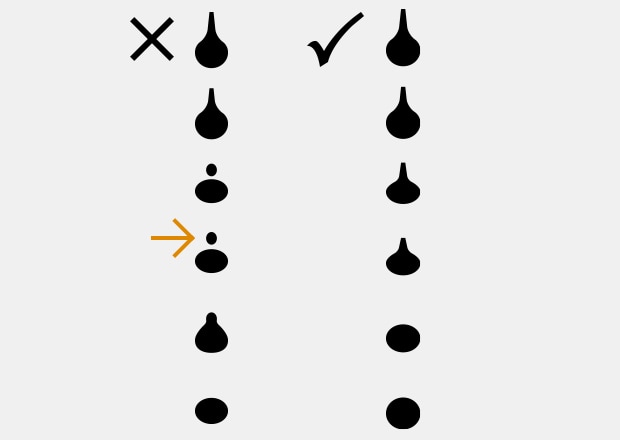

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Automatic ink particle optimization:

The MK-G Series senses the ink particles 10 times per second, so it can automatically adjust itself to maintain optimum ink particle conditions. Stable printing is ensured by suppressing the impact of temperature fluctuations.

Less-than-optimal state of particles

Optimal particle state

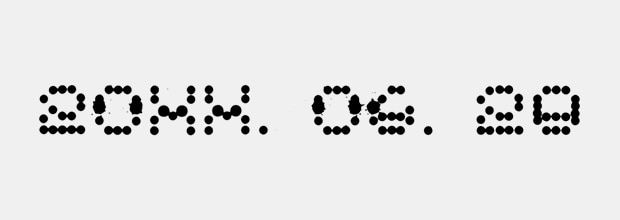

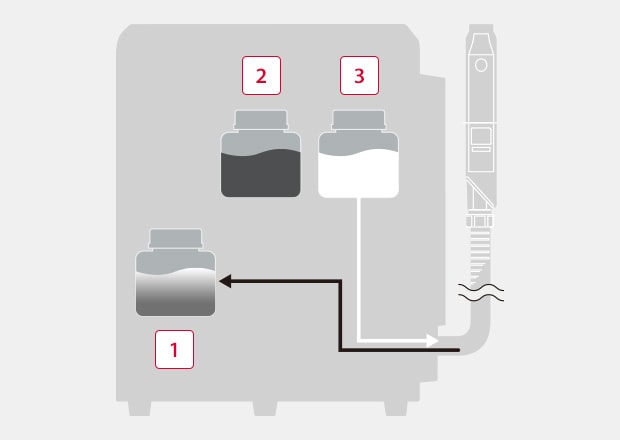

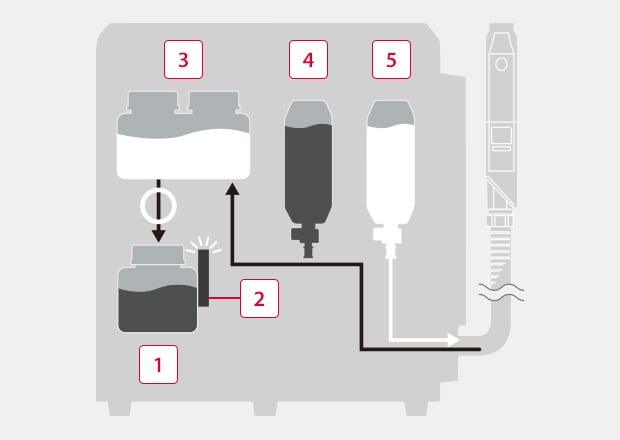

Conditioning tank system:

The MK-G Series is equipped with a viscosity sensor and a conditioning tank for collecting solvent after cleaning. This prevents ink dilution due to cleaning operations and wasteful disposal of solvent.

Without conditioning tank

When washing is performed, the ink viscosity decreases.

-

1Main tank

-

2Ink tank

-

3Solvent tank

MK-G Series

The conditioning tank is used for temporary storage to prevent dilution of the ink.

-

1Main tank

-

2Viscosity sensor [Sensor-based management]

-

3Conditioning tank

-

4Ink cartridge

-

5Solvent cartridge

Production Speed

Conventional systems can’t match CIJ production speeds. MK-G Series CIJs offer standard and proprietary features for fast coding and marking on nutraceutical packaging.

Discover more about this product.

Click here to book your demo.

CIJ for Nutraceutical Packaging

With stability and usability in mind, we offer our CIJ for the pharmaceutical and consumer products industry to help nutraceutical manufacturers efficiently complete lot/date coding on nutraceutical packaging.

Our MK-G Series industrial inkjet printers can be installed on cartoners, grip conveyors, hopper labelers, and other production lines for fast, durable, and reliable printing. Use the MK-G Series CIJ to accurately mark nutraceuticals for documentation, traceability, and compliance with regulations.

Curious about our pricing?

Click here to find out more.

FAQs about Coding and Marking in the Nutraceutical Industry

Why Are CIJ Printers Ideal for Lot/Date Coding on Nutraceutical Packaging?

The high-speed printing and capability to print on a range of surfaces make continuous inkjet printers an ideal solution for coding and marking on nutraceutical packaging.

Why Is Lot/Date Coding on Nutraceutical Packaging Important?

Lot and date coding on nutraceutical packaging lets manufacturers track and trace production batches, helping consumers make informed buying decisions.

How Does Coding and Marking on Nutraceutical Packaging Support Regulatory Compliance?

The pharmaceutical industry has strict regulatory standards requiring nutraceuticals to have clear and accurate coding for product identification, verification, traceability, and audits.

What Factors Should Be Considered When Choosing a Coding Solution for Nutraceutical Packaging?

Key factors for coding and marking on nutraceutical packaging include ease of integration, speed, durability, and print quality when selecting a product for marking solutions.

What Technologies Are Commonly Used for Coding on Nutraceutical Packaging?

Thermal inkjet (TIJ) printers, laser marking, hot stamping, and CIJs are popular options for coding lot/date information on nutraceutical packaging materials.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)