Welding quality requirements

Checking the quality of welding is extremely important, so comprehensive and stringent quality management is required. This page introduces various welding quality requirements.

- Quality of welding

- Weld joint and quality

- Joint efficiency and strength quality

- Welding defects and strength quality

Quality of welding

The following are typical requirements for the quality of weld products.

- The product is finished accurately in accordance with the design dimensions.

- The product offers the required functionality and strength (or safety).

- The appearance of the weld satisfies the required level.

The basic conditions of welding quality to achieve products of such high quality includes the following:

- No cracks or holes found in the bead.

- The bead has uniform waves, width and height.

- The finished product satisfies the design dimensions and has almost no distortion.

- The welding meets the required strength.

- Full penetration welds that fuse and join the entire interface between the base materials or a weld joints including partial penetration welds should be used appropriately to ensure the necessary rigidity.

Weld joint and quality

Except for some special base materials, the strength of weld joints is considered to be the same as that of the base materials.

There are many different types of weld joints based on the style of joining base materials. The strength of welding depends on which parts of the base materials are welded and how. Consequently, performing high-quality welding efficiently requires consideration of the directions of the forces that will be applied to the products after welding.

The penetration in a weld joint is important to the strength, quality, and operation efficiency of welding. It must be selected in accordance with the shape of the base materials and necessary strength. Weld joints are classified as shown in the table below based on the shape of the weld.

| Groove weld | Fillet weld | Plug weld | Slot weld | |

|---|---|---|---|---|

| Butt joint |

|

|||

| Cross joint Tee joint |

|

|

||

| Corner joint |

|

|

||

| Strapped joint |

|

|

|

|

| Lap joint |

|

|||

| Edge joint |

|

The classifications above are just an example. There are various ways to classify the types, and some may differ from the table above.

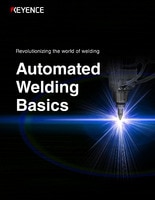

- Groove weld

- Workpieces are welded along a groove provided between them. Groove welds can be further divided into full penetration welds which fuse the entire interface of the base materials and partial penetration welds which fuse part of the interface.

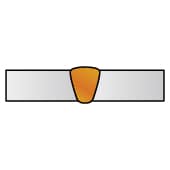

- Fillet weld

- Fillet welds join the surfaces of two base materials positioned at an almost right angle by using triangular welds, which forms a tee joint, a cross joint, or a corner joint.

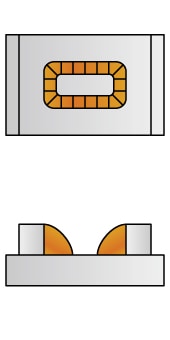

- Plug weld

- This is a type of joint welding in which a hole is drilled in the material that is laid over (or under) the other one.

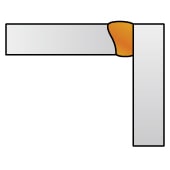

- Slot weld

- This is a type of joint weld in which an ellipse or elongated slot is drilled instead of the hole used in plug welds.

Groove welds and fillet welds are generally considered typical weld joints, and plug welds and slot welds are special joints. Butt welds refers to weld joints where the surfaces of the two base materials are almost flush with each other. In some cases, however, "tee joints" and "corner joints" where the surfaces of the base materials are not flush may also be called butt welds when the weld has full penetration.

Joint efficiency and strength quality

The strength quality of a weld joint has a close relationship with joint efficiency determined by the strength of the materials as well as with the welding process.

The relationship among joint efficiency, weld joint strength and the strength of base materials can be expressed as follows:

Joint efficiency = Strength of weld joint / Strength of base materials

For example, a butt joint of structural steel increases the strength of the weld metal and heat-affected zone to be higher than the strength of the base materials. When a load works in a direction perpendicular to such a joint, fractures are highly likely to occur in the base material instead of the joint. This is because the ductility and strength of the joint is equal to or higher than the strength of the base material. In this case, the joint efficiency can be estimated as 100% or higher.

On the other hand, high heat input welding of high-tensile steel or aluminum alloy or the welding of work-hardened austenite stainless steel or heat-treated aluminum alloys causes softening of the zone that was affected by heat during welding. If the resulted strength of the weld metal is lower than that of the base material, the joint fractures. In this case, the joint efficiency can be estimated as 70 to 80% or lower.

Welding defects and strength quality

In order to prevent welding defects and improve quality, it is important to select materials and processes suitable for the application in the welding design phase. Even if the design is appropriate, however, defects produced during welding will have a major influence on quality. For example, defects in a bead greatly affect not only appearance but also strength. This means that appearance defects such as pits, undercut, overlap, insufficient reinforcement, surface cracking, bead meandering, remaining groove and arc strike directly represent defects in welding quality.

The following pages describe examples of welding defects that greatly affect quality, inspection methods indispensable for maintaining quality, and the latest inspection examples that achieved streamlining through active adoption of technologies.