Electronics

Inspect for substrate warpage without stopping the line using a 2D laser profiler. The LJ-X Series can check for gaps between the carrier and the substrate without having to stop and scan the part with a 1D sensor, which reduces inspection time.

2D/3D Laser Profiler

LJ-X8000 series

Proper installation of the O-ring is critical for preventing oil leakage that could damage the ECU. Using the LJ-X8000 Series, you can check for accurate assembly and record measured values inline.

2D/3D Laser Profiler

LJ-X8000 series

Check for volume and even distribution of solder paste on PCB inline. Multiple areas can be inspected simultaneously from the 3D image.

2D/3D Laser Profiler

LJ-X8000 series

Reliably inspect terminal height and detect bent pins inline. Laser profilers capture a high resolution 3D image of the terminal shape, providing an accurate, non-contact method for sorting at high speed.

2D/3D Laser Profiler

LJ-X8000 series

Inspect stamped parts immediately after leaving the press to identify issues early and reduce scrap. The TM Series is a calibrated inline 2D measurement system that perfect for this type of high accuracy 100% inspection.

Telecentric Measurement System

TM-X5000 series

Measure the gap between the unit and cover glass prior to mounting the CMOS. By using a confocal sensor, such as the CL-3000, you can perform stable and accurate inspection even if the glass is tilted.

Confocal Displacement Sensor

CL-3000 series

Measuring the tiny vibrations of piezoelectric elements is now possible using high speed displacement sensors. The LK-G5000 has the accuracy and speed to capture these fine vibrations in the detail required to confirm the element is functioning properly.

Ultra High-Speed/High-Accuracy Laser Displacement Sensor

LK-G5000 series

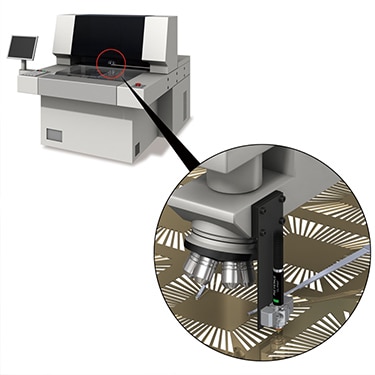

Reduce inspection time by using Z-axis position feedback to automatically bring lead frames into focus for image inspection. The CL-3000 is compact enough to fit almost anywhere and fast enough to support high speed control.

Confocal Displacement Sensor

CL-3000 series

Check the tilt of the elements after bonding. The CL-3000 Series uses the multi-color confocal method that enables coaxial measurement. No matter whether the target surfaces are specular or rough, they can be measured in the same setting, which achieves easy and highly accurate inspection.

Confocal Displacement Sensor

CL-3000 series