- Home

- Solutions

- Case Studies

- Vision Labs can see clearly now thanks to KEYENCE

Vision Labs can see clearly now thanks to KEYENCE

More than six in 10 people in the UK have some requirement for glasses, meaning the range of lens combinations required to suit all of their needs is almost infinite. Significant effort goes into the cutting, polishing and treatment of every lens. Given the importance of ensuring the correct prescription, and the proximity of the lens to the wearer's eye, any sort of defect simply cannot be countenanced.

One of the UK's leading manufacturers of bespoke lenses, and a partner of 20 years plus to many of the leading names in the dispensing optician sector, is Vision Labs Ltd. Its specialist facility at Kidderminster in Worcestershire processes millions of lenses every year, each one tailored to the needs of the individual customer.

A complex technical process

Raw plastic material is cut to the required geometry by CNC milling and turning equipment, before a high-speed polishing process smooths the lens and removes any remnants from the milling and turning processes. Each lens then undergoes a visual inspection and verification against the patient's prescription, before undergoing any treatments required such as tinting, UV protection and the application of scratch- resistant coatings and the latest multi-layer anti-reflection coatings, as needed.Anthony Woodhouse, Technical Manager of Vision Labs, explains: "Given the volume of lenses we process, any defect with a lens or issue with production needs to be identified and remedied quickly, or we face a backlog in production which can impact on our delivery schedules and overall service to customers."

"All of our processing equipment is calibrated to very tight tolerances – as little as two microns – to ensure the best possible product quality and life cycle for consumables. However, all CNC equipment can be prone to positioning errors over time, emanating from natural wear and tear, or moving parts which are coming to the end of their lives and require replacement."

"During manufacture, each lens is subject to various levels of stress and heat. If these are not managed correctly, issues may arise which mean the lens may be rejected. In that event, we have to spend time investigating what has happened to determine the root cause then take any remedial action needed."

Machining accuracy is vital

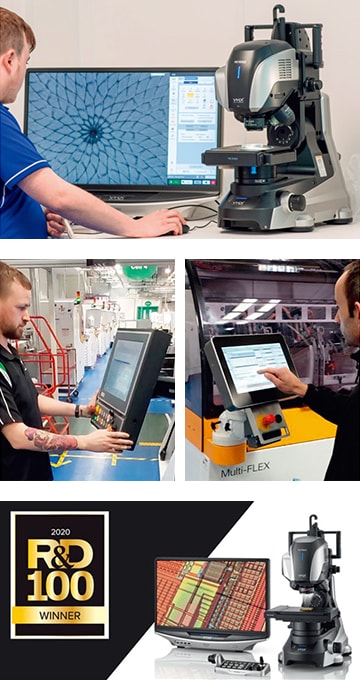

"Key to minimising the risk of defects is ensuring optimal machining machine tool accuracy. Previously we assessed this based in tool displacement using an eye glass with a scale. However, this method has limitations, even for the highly experienced tool setters within our team" says Anthony Woodhouse.Because of these challenges, the management team at Vision Labs sought another solution, and it came in the form of a KEYENCE VHX-7000 digital microscope.

The system's high magnification and 4,000 pixel count – the world's first microscope to offer this – combined with two-dimensional edge detection software which snaps to the lines of contrast meaning the risk of differences between users is eliminated, allows calibration tolerances as low as 0.1 microns.

Meanwhile, the glare removal feature and rapid 3D depth composition, combined with the VHX's easy-to-use of software, meant that wear on diamond cutting tools can be rapidly assessed to ensure they are replaced only when needed, creating cost savings for Vision Labs.

Perhaps the greatest benefit has come in the area of analysing coatings, where the VHX's world first optical shadow effect mode (OPT-SEM) allows these transparent features to be viewed more readily and so defects identified more rapidly. The multi-lighting feature, allowing immediate change between ring, coaxial, polarised and transmitted lighting, also assists the clarity of view.

Anthony Woodhouse continues: "The KEYENCE microscope is easy to use and gives us incredibly accurate and detailed information. removes the issues associated with the previous visual testing, as it enables us to calibrate our machines extremely accurately and counter any issues in our processes. It has enabled us to view defects in a way that was not possible before, equipping us with a better understanding of how they occur – and how we can minimise the risk of defects."

"We had used other KEYENCE equipment with great success for a number of years and so we were already aware not just of the quality of their products, but the depth of support and training that would be provided. The feedback from colleagues has been fantastic. Overall, we have great confidence in both the equipment and the KEYENCE team."

"This latest investment in KEYENCE equipment has resulted in higher-quality products, fewer interruptions to production and enhanced cutting tool lifetimes – meaning a significant impact on our productivity, service and the bottom line."

APPLICABLE PRODUCT CATALOG

Related Products

-

- 3D Surface Profiler

VK-X3000 series -

The VK-X3000 3D Surface Profiler uses a triple scan approach, where laser confocal scanning, focus variation, and white light interferometry measurement methods are used, so that high-accuracy measurement and analysis can be performed on any target. The VK-X3000 has a resolution of 0.01 nm and can scan areas up to 50 × 50 mm (1.97″ × 1.97″), allowing for measurement of the overall shape of the target while still maintaining high-resolution for analysis of minute surface features. KEYENCE's new 3D Surface Profiler can handle any target, including those with transparent or mirrored surfaces, large height changes, or steep angles.

- 3D Surface Profiler

-

- 3D Optical Profilometer

VR-6000 series -

The VR-6000 optical profilometer performs non-contact measurement to replace stylus profilometers and roughness meters. This 3D profile system captures full surface data across the target with a resolution of 0.1 µm, enabling measurement of features that cannot be performed with probe-type instruments. The new rotational scanning greatly expands the measurement capabilities of the system. True-to-life cross section measurements can be performed with no blind spots. Wall thicknesses and recessed features can be measured without cutting or destroying the target. In addition, the HDR scanning algorithm provides enhanced scanning capabilities for instantly determining the optimal settings to capture high quality data, even on glossy and matte surfaces.

- 3D Optical Profilometer

-

- 3D Scanner CMM

VL-800 series -

The VL-800 Series 3D Scanner CMM is the first in its lineup to feature 3D-AI, making high-quality 3D data acquisition and analysis effortless for any user. The system intelligently recommends optimal scanning, stitching, and measurement methods based on the shape of the part being analyzed. Additionally, scanned parts can be directly compared to their CAD models for quick visualization of differences, or the 3D scan can be used to streamline reverse engineering processes. From scanning to STEP file output, the VL-800 handles everything automatically, and provides accurate data in a format accessible by any CAD software.

- 3D Scanner CMM

- PLEASE

CONTACT US