Industrial Laser Marking Systems / Laser Markers

How to Choose the Right Laser Marker for Engraving

-

Tags:

- Laser Engraving , Metal

Wondering what a laser engraver is or how a laser engraver works? Or maybe you want to know what types of laser engraving machines lead to a more efficient, permanent, and user-friendly engraving process.

Then, there’s the question of which technology best fits your application.

Those in the manufacturing space come with many unique requirements for their production processes. Understandably, this raises questions and concerns surrounding the features and capabilities of laser engraving machines.

Choosing the right laser marking technology includes taking a look at different laser marking systems, their components, applications, and more. This laser engraving machine guide will get all the actionable information you need on how to choose the right laser marker for engraving.

Definition of Laser Engraving

Laser engraving uses a laser marker to remove material by vaporization to create deep or shallow marks. The material removed can be for a design, logo, or character. Used across various industries, options for engraving include hand engraving, roll markers, and press markers.

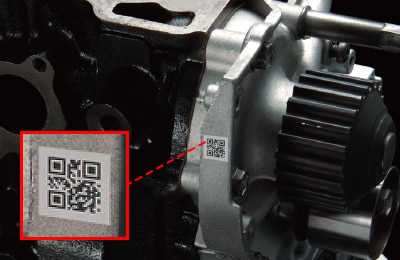

There are a couple of reasons why you may choose to engrave a material. One common reason is for traceability purposes, especially in manufacturing. For this, you may engrave a serial number or 2D code onto a jig or product part.

Another choice is engraving a design or character onto a product for identification. This could also be a serial number or a logo. Lastly, laser engraving may be a tool for removing resin to analyze the inside of a product.

We’re here to provide you with more details.

Reach out today!

Introduction to Laser Marking Technologies

Laser engraving technology works by using a combination of design software and a laser beam. First, the design is created and then uploaded to the design software program. Once the item is placed on the assembly line tray and gets to the correct position under the laser marker, the laser beam passes over the area to engrave the surface precisely.

The efficacy of this process has become a standard in many industries worldwide. While it is true that this level of quality can offer a competitive edge, the technology has much more to offer than that alone. Once you get an idea of the variety and capable range of these devices, alternative methods will seem completely outdated.

Although laser engraving technology has been around for quite some time, modern advancements continue to impress. Integrating such technology into your processes is easier than you think, but it has to start with understanding how to select the right laser marker for engraving.

*These are representative values. They will vary depending on the material and marking conditions

Discover more about this product.

Click here to book your demo.

Types of Materials That Can Be Engraved

Metal

Many subcategories of metal can be engraved with a fiber laser or a hybrid laser. The fiber or hybrid laser uses a high output to deeply engrave into the metal for characters, designs, and barcodes. Using a laser marker to engrave metal is the best choice since it is permanent, powerful, and does not ruin the material.

Wood/Cardboard

Wood or cardboard can be engraved with white or dark marks by CO2 laser. The CO2 laser uses high-powered heat to burn designs, logos, barcodes, and characters into wood or cardboard. Using CO2 engraving on wood or cardboard creates a permanent, high-contrast mark that beats stamping.

Plastics

Plastic is an oftentimes sensitive material that is susceptible to deformation when heated. For this reason, a UV laser is the perfect option. It performs what is referred to as “cold marking” in which a fully permanent, high-contrast mark can be created without the application of any heat. For less demanding plastic marking apps, a hybrid or CO2 laser can often be a great option as well.

Glass

Glass can be engraved with white or transparent marks by CO2 or UV laser. Since glass is fragile yet heat resistant, laser engraving glass is a reliable and efficient choice for damage-free marking. The CO2 and UV laser use low or slow power to create cracks that don’t ruin the rest of the product.

Rubber

Whether it’s synthetic or natural rubber, laser engraving can make a permanent and high-contrast mark without ruining the material.

Natural rubber is sensitive to heat and is commonly used for hoses. Using a hybrid laser to engrave natural rubber is optimal because it doesn’t compromise the material but also creates a permanent mark. On the other hand, synthetic rubber is not sensitive to heat and is used for products like wiper blades because of its durability. CO2 lasers adequately engrave permanent marks because of the high absorption rate from the CO2.

We’re here to provide you with more details.

Reach out today!

Popular Applications of Laser Engraving

There is a long list of applications that laser engraving is optimal for, including:

- Implants

- Deep engraving on metal

- Nameplates

- Bearings

- Automotive parts

- 2D code marking

Understanding Different Types of Laser Markers

On the surface, varying types of lasers can seem confusing to navigate. However, it is easier to focus on core features and components to help highlight their main differences. UV and fiber laser engraving are some of the most common designs on the market, but there are several popular laser types for a reason. Some are a bit more diverse than others.

Here are several popular types of laser engraving machines:

- Fiber laser

- UV laser

- CO2 laser

- Hybrid laser

- Green laser

The manufacturing industry can expect this technology to expand in short order, as it is already making impressive strides in production as is. It is vital not to copy and paste these lasers into your manufacturing processes, as a specific design may be better suited to your needs. In short, comparing the various specifications, features, and capabilities of different machines will help lead you down the right path.

Curious about our pricing?

Click here to find out more.

Laser Engraving Machines

At KEYENCE, we offer hybrid, fiber, CO2, and UV laser marking machines for any project.

3-Axis Fiber Laser MD-F Series

The 3-Axis Fiber Laser MD-F Series is a fiber laser with an output of either 50W or 30W. The high output allows for the laser to achieve high speed and deep engraving. This laser is perfect for deep engraving into metal.

- High power output

- Compact head

- Multi-mode beam

- Scanning function selection

Engine blocks

Vehicle body frames (deep engraving)

Bearings

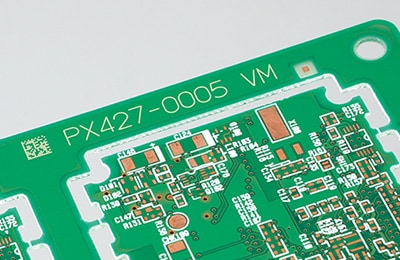

3-Axis CO2 ML-Z Series

The 3-Axis CO2 ML-Z Series is a CO2 laser that engraves by burning and high absorption. Using a CO2 laser is great for shallow engraving into sensitive or heat-resistant materials like glass, wood, cardboard, paper, and synthetic rubber.

- High power

- High speed

- Stable output

- Long shelf life

PCBs

Partial cutting of labels

Film processing

3-Axis Hybrid Laser MD-X Series

The 3-Axis Hybrid Laser MD-X Series uses the best aspects of a YVO4 and fiber laser to engrave materials. The YVO4 adds high quality and depth of focus, while the fiber laser has long service life and a high output. This laser can engrave metal, resin, and natural rubber.

- Versatile

- High peak power

- Single-mode beam

- Long expected life

Molded packages (BGA)

Edged tools (black-annealed marking)

Switches for automotive instrument panels

3-Axis UV Laser Marker MD-U Series

The 3-Axis UV Laser Marker MD-U Series uses ultraviolet light and heat absorption to engrave heat-sensitive materials. The UV laser is perfect for engraving plastics, glass, and other heat-sensitive materials.

- High contrast

- Damage free

- Minimal maintenance

- Digital scanner

Switch covers (PP)

Medical tubing (silicone)

Multicolor automotive relays

Get detailed information on our products by downloading our catalog.

View Catalog

Factors to Consider When Selecting a Laser Marker

To ensure the best outcome for your business and customers, choosing the right laser marker for engraving includes a few specific factors. Whether it is laser marking food industry products or comparing the likes of fiber vs CO2 lasers, all of the nuances matter. In the list below, you can find a few important factors you should take with you when sorting through how to select the right laser marker for engraving.

- Your operational needs

- The material compatibility of the laser

- Current and potential laser marking applications

- How you expect to integrate it with your current systems

Some of these points will vary from one business to another. Overall, assessing the details is your best shot at selecting the right laser marker for your production requirements.

Advantages of Laser Engraving

Efficient

Laser engraving is more efficient than its manual engraving counterparts. With a laser marker, tens of characters per assembly line tray can be marked in an instant.

KEYENCE’s laser markers are equipped with 3-axis control and autofocus. These laser markers analyze the product's placement and change the focal point accordingly. Because of this, there is no need for product repositioning.

Laser engraving is also more efficient than using a handheld device. The automation eliminates human error, breaks, and tedious handheld marking.

Damage Free

Laser engravers use heat or high absorption to mark on materials instead of added force. The pointed beam concentrates the energy to only mark in the respected area and not expand to the rest of the material.

High Quality

Unlike stamping or handheld drill devices, laser engraving can get deep into materials. The deep cuts from laser engraving leave behind high-quality marks that are clean, last forever, and don’t fade over time.

We’re here to provide you with more details.

Reach out today!

Step-by-Step Guide to Choosing Your Laser Marker

To help provide a more straightforward approach to your laser marking technology search, the following steps can act as your guide from start to finish.

- 1. Assess materials and immediate production requirements

- 2. Compare the laser compatibility with materials

- 3. Review safety or regulation requirements

- 4. Consider integration, efficiency, and maintenance outlook

- 5. Consult with experts before, during, and after for the most seamless approach

Most actions in the manufacturing space start with making an informed decision, but this isn’t always easy. For answers to your questions, additional guidance, and expertise on the topic, talking to those who truly understand the technology can help.

Discover more about this product.

Click here to book your demo.

Get Feedback to Make an Informed Decision

Laser engraving is a more efficient, damage-free, and high-quality alternative to engraving counterparts. There are many laser engraving markers to choose from to get the best result with your material and production goals.

Have a laser engraving project in mind and need assistance? Our trained team is here to help. At KEYENCE, we have knowledgeable staff that will help you throughout your selection process, on-site operating instructions assistance, as well as industry-leading after-sales support.

We’re here to provide you with more details.

Reach out today!

Related Downloads

KEYENCE's MD-F Series offers unmatched functionality in a compact design.

This quick guide introduces the basics of metal marking. Learn why different wavelengths matter and discover the various ways laser light interacts with metal parts.