Laser Marking Systems / Laser Markers

Laser Marking in the Pharmaceutical Industry

-

Tags:

- Laser Marking , Plastic , Food and Pharmaceutical

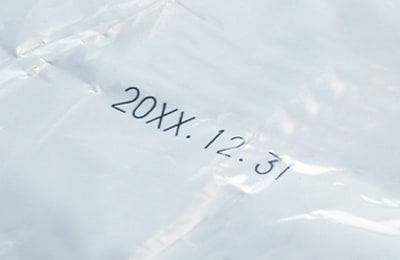

Due to its unparalleled accuracy and dependability in marking product information, laser marking in the pharmaceutical packaging industry has emerged as a key component. With the use of laser technology, each package is guaranteed to meet the stringent safety and traceability standards set by the industry, which include batch numbers, expiration dates, and serialization codes.

Because pharmaceutical laser marking systems create permanent, high-contrast markings without the need for consumables, they offer a number of attractive advantages.

We’re here to provide you with more details.

Reach out today!

The Importance of Laser Marking in Pharmaceutical Packaging

In the highly regulated pharmaceutical industry, compliance, precision, and safety are non-negotiable, especially when it comes to packaging. Pharmaceutical packaging requires laser marking because it produces codes that guarantee traceability, lower counterfeiting, and satisfy strict regulatory requirements.

Applications of Laser Marking in Pharmaceutical Packaging

Laser marking fulfills a number of purposes for both primary and secondary pharmaceutical packaging.

Primary Packaging

Primary packaging directly contains the pharmaceutical product, making accurate and durable marking essential. In this application, laser marking works exceptionally well, producing accurate and readable codes without sacrificing the integrity of the container or its contents. Since laser marking does not use any additional material, there is no worry of chemicals contaminating the product. Examples include:

- Autoinjector pens

- Glass vials

- Plastic ampoules

- Plastic bottles

- Rigid tubes

- Blister packs

Vials & Ampoules

Plastic bottles

Blister packs

Autoinjector devices

Secondary Packaging

Secondary packaging protects and groups primary packages, and laser marking ensures clear identification, branding, and traceability across supply chains. Examples include:

- Clamshell blister packs

- Cardboard boxes and cartons

- Shrink wraps

- Flexible pouches

- Sample and starter kits

Film & pouches

Shrink wraps

Cardboard boxes & cartons

Benefits of Laser Marking for Pharmaceutical Packaging

Pharma operations utilize laser marking packaging for its many benefits, including:

- Meeting regulatory compliance

- Preventing counterfeits

- Creating precise, non-contact marks

- Improving cost efficiency

- Reducing environmental footprint

Essential for meeting stringent pharmaceutical regulations, laser-marked packages ensure that clear, durable codes—such as batch numbers, expiration dates, and barcodes—comply with FDA, EU, and other global standards. Precision like this helps manufacturers avoid costly recalls or regulatory penalties.

Permanent, tamper-proof markings also protect product integrity and brand reputation by making packaging much more difficult to copy or modify. Because laser technology is non-contact, it can produce excellent markings without endangering the packaging or its contents. With laser marker software, you can effortlessly switch between codes, adjust label size or font, and modify power settings to suit your application.

Since laser engraving does not require additional materials like ink, ribbons, or chemicals, it can make traceability easier and more affordable. The lack of chemicals means that additional testing on primary packaging can be avoided since there is no worry of chemicals leaking through and altering the medication. As for secondary packaging, the lack of consumables means that laser engraving does not have a recurring cost associated with it.

Lastly, because it produces minimal waste and does not use potentially hazardous chemicals, it lessens the environmental impact of manufacturing processes and is in line with sustainability goals.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Pharmaceutical Packaging Laser Marking FAQs

What types of pharmaceutical packaging can be laser marked?

A variety of materials, such as foil, cardboard, plastics, and glass, can be marked with a laser. It is versatile enough to handle both primary (e.g., vials, ampoules) and secondary (e.g., clamshell blister packs, boxes) packaging.

How does laser marking ensure compliance with regulations in the pharmaceutical industry?

Permanent codes produced by laser marking satisfy legal specifications as high-intensity laser beams create precise, tamper-proof markings directly on the material surface.

How can laser marking help prevent counterfeiting in the pharma supply chain?

Supply chain security is improved by laser technology, which makes it much more difficult for counterfeiters to duplicate packaging by enabling unique serializations, QR codes, and holographic markings.

Can laser marking handle curved or irregular surfaces in pharma ackaging?

Yes, KEYENCE laser marking systems are designed to adapt to complex geometries, providing consistent, legible codes on curved or irregular surfaces like ampoules and autoinjector pens.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Application Guide [High Contrast Marking]](/img/asset/AS_95184_L.jpg)