Industrial Laser Marking Systems / Laser Markers

UV Laser vs Fiber Laser Engraver: What's the Difference?

-

Tags:

- Laser Engraving , Laser Etching , Electric Vehicle

In the debate of using UV lasers vs fiber lasers for engraving, each technology has a purpose in manufacturing. In the following, we will explore both for a better understanding of how they work, their unique benefits, how and where the technology can be applied, and, ultimately, their full potential.

Definition of UV Laser

A UV laser is a laser that uses ultraviolet light to mark materials.

First, a 1064 nm laser is converted into a 355 nm laser through two crystals. Then, the 355 nm beam breaks down bonds directly using a photolytic degradation process. This process is known as “cold marking” because it does not burn surface areas and uses minimal heat stress. KEYENCE’s UV laser marking machine is the 3-Axis UV Laser MD-U Series.

Definition of Fiber Laser

A fiber laser is an infrared laser with a wavelength of 1090 nm. The fiber laser uses heat to cut, engrave, mark, etch, and remove burr. Fiber lasers work great with metals and can be a more affordable option. Widely used for deep engravings and many other production processes, fiber lasers are a go-to choice for many manufacturers.

Even with its efficacy as a laser engraver for metal, this laser design is not perfect for every engraving situation. That is why getting the full scope on fiber laser vs UV laser specifics is crucial so you know how and where to adapt them. KEYENCE’s fiber laser marking machine is the 3-Axis Fiber Laser MD-F Series.

We’re here to provide you with more details.

Reach out today!

Benefits of UV Laser

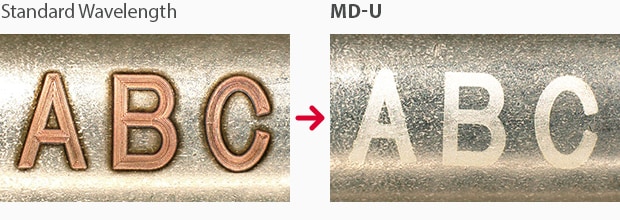

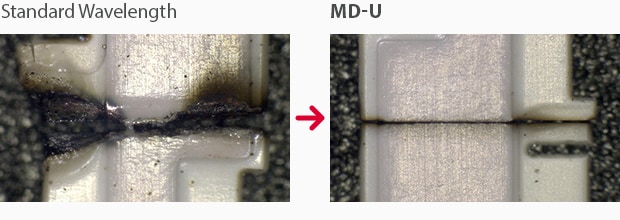

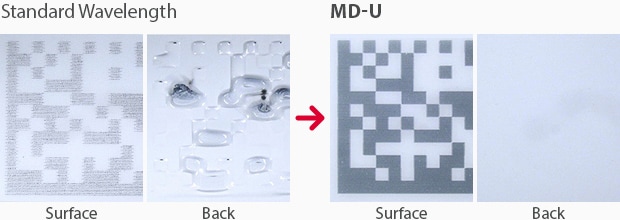

Damage-Free Marks

UV lasers break down bonds directly, so minimal heat stress is used when marking. Because of this, no residue of burrs or yellow tinting is left over on the marked materials.

The high-energy photons in UV lasers allow for photolytic degradation processing that breaks the bonds between molecules directly. This allows for marking and processing without heat being applied to surfaces, thus minimizing damage.

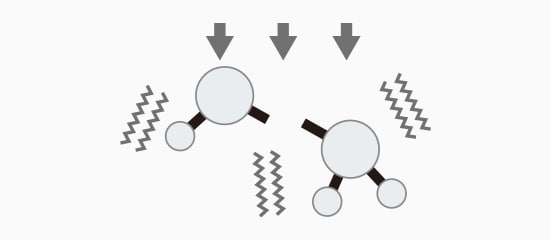

Thermal Processing

Bonds are destroyed using heat to vibrate the molecules.

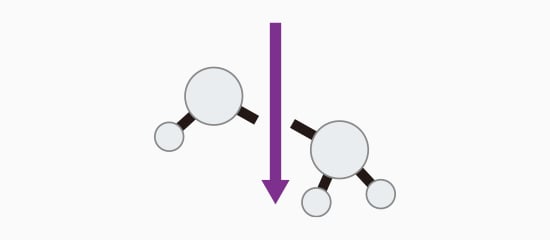

Photolytic Degradation Processing

Bonds are broken with light, resulting in less heat.

Easy Marking on Sensitive Materials

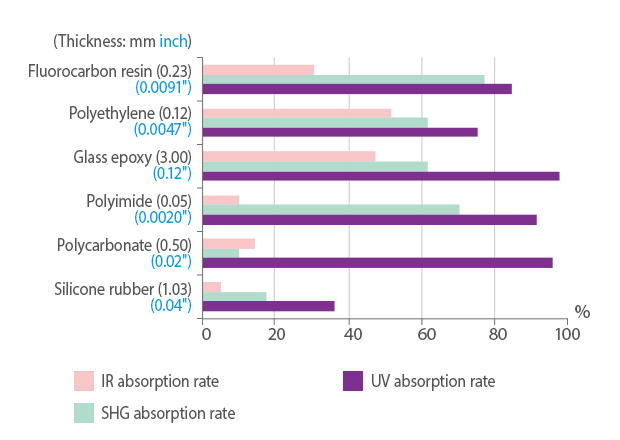

Since UV lasers do not rely on heat marking and use absorption, these lasers can mark materials that are heat sensitive and may be damaged by fiber lasers.

Heat-sensitive materials that a UV laser can mark are:

Marking Silver-Plated Surface

Cutting PCB

Marking Transfusion Bag Film

Marking IC Package

Advantages of UV Laser Engraver

Absorption rates for various resin materials

* The values are for reference only and do not account for surface reflectivity

High Absorption Rate

A UV laser has a 355 nm laser with an incredibly high absorption rate. This means that even with materials that have high melting points, like glass or metal, the UV laser can still mark them without using high power. Additionally, since the absorption rate is so high, the laser does not damage the material.

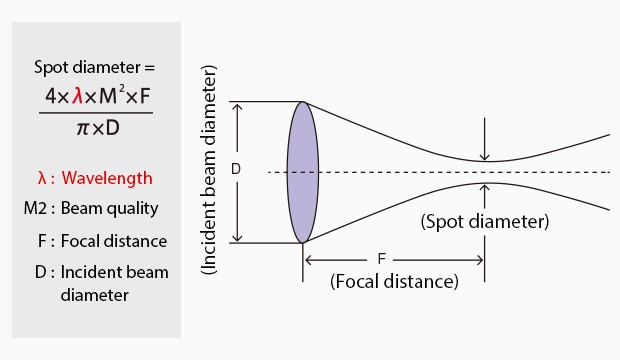

Laser marker spot diameter

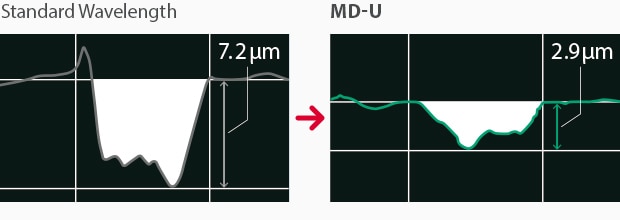

Small Spot Diameter

The MD-U Series’ UV wavelength is 1/3 the length of a standard laser, which leads to a smaller beam diameter. Because of this, the UV laser only marks precisely on the spot it needs to. Therefore, there is no swelling across the material that could cause deformation.

Additionally, the small spot diameter allows for marking on small products with intricate detailing. Some examples are 2D codes, plastic tubes, gas meter casings, and in-vehicle plastic parts.

Discover more about this product.

Click here to book your demo.

Benefits of Fiber Laser

Increased Efficiency with Output

Fiber lasers are known for their high output making for quicker production times. The MD-F Series has two choices of outputs, 30 W and 50 W. With these outputs, the fiber laser can mark, cut, engrave, and anneal materials fast.

High Contrast Metal Marking

For metals like iron that are not highly reflective, the fiber laser can create high contrast marks. Other lasers that have high absorption rates cannot achieve the same effect quickly.

Advantages of Fiber Laser

Scratch Control

Fiber lasers are a good choice for cutting materials because of their high output. The 3-Axis Fiber Laser MD-F Series has scratch control, which allows for clean cuts. The cutting process moves the fiber laser beam back and forth across a short distance. Since the fiber laser beam moves across a short distance, the energy is focused. This results in speedy processing time and clean cuts.

Wobble Control

The MD-F fiber laser achieves high-quality annealing with wobble control. The Wobble control makes the laser move in a circular pattern rather than overlapping single lines. The circular pattern ensures thick characters and concentrated energy.

Deep Engraving Control

The high output of 50 W not only marks fast, but it can engrave deeply. The output's high heat digs deep into materials. With the deep engraving control of the MD-F, the focal distance varies for each laser pass. Because of this, the maximum energy density is achieved throughout the marking.

We’re here to provide you with more details.

Reach out today!

Differences Between UV and Fiber Lasers

Type of Laser

From a foundational standpoint, a UV laser vs a fiber laser differ greatly. UV lasers use ultraviolet light, while fiber lasers use an infrared light. Additionally, the UV laser is 355 nm while the fiber laser is 1090. Since they have different types of light, each laser has a separate process of marking. Fiber lasers use high heat with high output to mark materials, while UV lasers use absorption to break down bonds.

UV Laser Applications vs Fiber Laser Applications

A UV laser does not rely on heat for marking, so it can mark heat-sensitive materials without damage. On the other hand, fiber lasers do use heat, so they do not have the capability of marking on heat-sensitive materials without damage. However, fiber lasers may be better for certain metals like iron because of the high output creating high contrast.

Speed

When it comes to speed, choosing a UV laser vs a fiber laser depends on the material that you are looking to mark or process. The fiber laser has an output of 50 W, whereas the UV laser has an output of 3 W. Typically this means that the fiber laser would be faster when it comes to marking, cutting, or engraving. However, there are materials, like plastics, that the higher absorption of the UV allows it to mark or engrave faster than the fiber, regardless of the wattage difference.

Similarities of Fiber and UV Lasers at KEYENCE

3-Axis Control

The 3-Axis UV Laser MD-U Series and the 3-Axis Fiber Laser MD-F Series at KEYENCE both have 3-Axis control. The 3-Axis control allows for both lasers to mark perfectly on any surface, even 3D surfaces. It works by using an adjustable focal point rather than a fixed focal point like other conventional lasers. When a product is under the laser, the focal point can adjust to the part height ensuring an in-focus mark regardless of changing part height or 3D part shapes.

Get detailed information on our products by downloading our catalog.

View Catalog

UV Laser vs Fiber Laser Engraver in Manufacturing

Looking at this technology from a bird’s eye view involves more than the main difference between UV and fiber lasers. Nevertheless, it can’t be ignored that this is one of the core areas of debate surrounding UV laser vs fiber laser comparisons.

As a manufacturer, choosing between the two considers specific nuances of your specific operation. While some businesses may benefit more from UV, others may only need the output and quality that fiber laser engraving offers. Both designs are more than enough in their own right, but providing additional points side by side can help you align the right equipment for your production needs.

For example, some organizations prefer the low heat output of UV laser engravers, as this makes them a great choice for more sensitive materials. The differences between UV and fiber lasers can be seen in the final quality.

While each is more than satisfactory, UV lasers are proven to create smaller spot sizes than fiber lasers. This makes for a more seamless look on non-metal materials.

Potential Innovations and Trends Shaping the Future of UV vs Fiber Laser Engravers

There are many known current applications for fiber and UV laser marking and engraving, but what does this mean for the technology's future?

Here are a few popular innovations and trends with UV and fiber lasers:

- More in-depth integrations with AI and machine learning.

- Better energy efficiency and sustainability practices.

- Laser source technology is bound to improve with time.

- It will eventually become even more cost-effective.

- More applications with eco-conscious manufacturing and recycling efforts.

The list of applications, use cases, and benefits of these tools is ever-growing. We’re living in a technological era full of innovation, which will only make the laser engraving process all the more relevant. If your organization is looking to make your way into the territory of deep laser engraving, you want to work with the experts on the matter.

KEYENCE’s Comprehensive Range of UV and Fiber Laser Engravers

KEYENCE has decades of experience with laser marking equipment, including UV and fiber laser engravers. Whether you’re focused on laser etching vs engraving or stuck deciding on the type of laser, you can trust we have the quality and variety you need. Here are a few of our most popular engraving machines:

- UV Laser Markers (MD-U Series)

- Fiber Laser Markers (MD-F Series)

- 3-Axis Hybrid Laser Marker (MD-X Series)

- Telecentric Green Laser Marker (MD-T Series)

Most consumers won’t settle for less, which means manufacturers will need to keep up with quality standards found in the most recent technology. Traditional methods of laser marking food packaging, car parts, and many other common items are still very relevant.

Conclusion

UV lasers and fiber lasers each have specifications that make them optimal for certain production projects. If your project includes marking heat-sensitive materials or marking on small objects, choosing a UV laser is best. However, if you are looking for a high-speed laser that can achieve clean cuts, engraving, or annealing on metal, you may want to choose a fiber laser.

Whichever you choose, UV laser vs fiber laser, KEYENCE is here to help. At KEYENCE, we have a knowledgeable team that will help you throughout your selection process to operations with on-site operating instructions, along with industry-leading after-sales support.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

KEYENCE's MD-F Series offers unmatched functionality in a compact design.

This quick guide introduces the basics of metal marking. Learn why different wavelengths matter and discover the various ways laser light interacts with metal parts.

![UV Laser Marker Application Guide [High Contrast Marking]](/img/asset/AS_95184_L.jpg)