Data Acquisition (DAQ)

Basic Knowledge of Temperature Data Loggers

Temperature sensors such as thermocouples and resistance thermometers are connected to a temperature data logger. The measured temperature is then recorded in the temperature recorder. This section explains the specifications of temperature data loggers, how to read them, and their reliability during temperature data collection.

Temperature Data Logger Specifications

When selecting a temperature data logger, you need to understand the meanings of terms written in the specifications. This section explains how to read the specifications of temperature data loggers.

Number of Channels

Indicates the number of points (channels) from which the temperature data logger can collect data.

Measurement Cycle

Refers to the speed at which to sample analog signal information, which indicates at how many seconds one point is sampled. The measurement cycle is also called the sampling cycle.

A/D Resolution

The resolution for A/D conversion is generally expressed as several bits.

If the resolution is 16 bits, a full-scale value divided by 2 to the 16th power (65536) is the minimum resolution during A/D conversion.

Input Type

Indicates the type of signals that can be input to the temperature data logger.

Maximum Input Voltage (Rated)

The maximum voltage value that can be applied between the + and − terminals of the input without breaking it. The maximum input voltage does not indicate the measurable voltage value.

Input Impedance

Indicates the resistance value when a signal is input to the input unit of the temperature data logger.

Measurement Accuracy

Indicates the accuracy of the temperature data logger. The measurement accuracy is represented in two ways: FS (full scale or entire measurement range) and rdg (reading). In general, the rdg representation offers higher accuracy.

Also, as the actual measurement accuracy, a shift amount is often added as “± XX digit (XX°C/°F).”

Example: The statements “±0.1% of FS” and “±0.1% of rdg” are compared below in terms of the measurement accuracy when “100°C (212°F)” is measured in a K thermocouple range.

- ±0.1% of FS FS = 1572°C (2861.6°F)

This results in a measurement accuracy of ±0.1% × 1572°C (2861.6°F) = ±1.572°C (2.8616°F) - ±0.1% of rdg rdg (reading) = 100°C (212°F)

This results in a measurement accuracy of ±0.1% × 100°C (212°F) = ±0.1°C (2.12°F).

Reference Junction Compensation Accuracy

This specification indicates the accuracy relevant to temperature measurement using a thermocouple.

A thermocouple measures the temperature difference between two different types of metal junctions (temperature measuring junctions) and the junction on the temperature data logger side (reference junction) and adds the temperature measured at the reference junction to measure the temperature of the temperature measuring junctions.

The reference junction compensation accuracy shows the accuracy of the reference junction temperature.

The table below lists the specifications of a typical temperature data logger.

|

Input method |

Floating unbalanced input, channels insulated from each other, inputs insulated from other units (PC), channels not insulated from each other for a resistance thermometer |

|||||

|

Number of channels |

8 input channels, 64 channels with the maximum expansion (when 8 units are connected) |

|||||

|

Measurement cycle |

Maximum sampling cycle: 100 ms (AD integration time: 2 ms) to 1 hour |

|||||

|

A/D conversion method |

Delta-sigma method |

|||||

|

A/D resolution |

16 bits |

|||||

|

A/D integration time |

2 ms, 16.7 ms, 20 ms |

|||||

|

Input types and voltage |

Voltage: ±50 V, ±10 V, ±5 V, ±1 V, ±0.5 V, ±0.1 V |

|||||

|

Thermocouple: K, J, E, T, R, S, B, N, W |

||||||

|

Resistance thermometer: Pt100, JPt100, 3 wires, specified current 1 mA |

||||||

|

Reference junction compensation |

Switchable between internal and external (individual unit setting, 0°C 32°F for external) |

|||||

|

Reference junction compensation accuracy |

±0.7°C 1.26°F (23°C ±2°C 73.4°F ±3.6°F, at input terminal temperature equilibrium) |

|||||

|

Maximum input voltage (rated) |

±60 V (CAT I) |

|||||

|

Input impedance |

Thermocouple, 5 V range or less |

10 MΩ or more |

||||

|

50 V and 10 V range |

Approx. 1 MΩ |

|||||

|

Withstand voltage |

Between measurement input terminal and system bus |

1500 VAC (50/60 Hz) 1 minute |

||||

|

Between measurement input terminals |

120 Vp-p AC/DC |

|||||

|

Input signal source resistance |

Voltage, thermocouple |

2 kΩ max. |

||||

|

Resistance thermometer |

10 Ω max./wire (equal among three wires) |

|||||

|

Thermocouple burnout |

Wire breakage detected in the thermocouple range by applying 1 µA of current |

|||||

|

Burnout detection cycle |

Detected in the measurement cycle |

|||||

|

Resistance thermometer |

Measurable range |

Measurement accuracy(A/D integration time: 16.7 ms, 20 ms) |

Display resolution |

|||

|

±50 V |

−55.00 to +55.00 V |

±0.05% of rdg ±2 digits |

10 mV |

|||

|

±10 V |

−11.000 to +11.000 V |

±0.05% of rdg ±2 digits |

1 mV |

|||

|

±5 V |

−5.500 to +5.500 V |

±0.05% of rdg ±2 digits |

1 mV |

|||

|

±1 V |

−1.1000 to +1.1000 V |

±0.05% of rdg ±2 digits |

0.1 mV |

|||

|

±500 mV |

−550.0 to +550.0 mV |

±0.05% of rdg ±2 digits |

0.1 mV |

|||

|

±100 mV |

−110.00 to +110.00 mV |

±0.05% of rdg ±2 digits |

0.01 mV |

|||

|

K |

−100°C to +1372°C (−148°F to +2501.6°F) −200°C to −100°C (−328°F to −148°F) |

±0.05% of rdg ±0.6°C (±1.08°F) |

0.05°C (0.09°F) |

|||

|

J |

−100°C to +1200°C (−148°F to +2192°F) −200°C to −100°C (−328°F to −148°F) |

±0.05% of rdg ±0.6°C (±1.08°F) |

0.05°C (0.09°F) |

|||

|

E |

−100°C to +1000°C (−148°F to +1832°F) −200°C to −100°C (−328°F to −148°F) |

±0.05% of rdg ±0.6°C (±1.08°F) |

0.05°C (0.09°F) |

|||

|

T |

−100°C to +400°C (−148°F to +752°F) |

±0.05% of rdg ±0.5°C (±0.9°F) ±0.05% of rdg ±0.8°C (±1.44°F) |

0.01°C (0.018°F) |

|||

|

N |

0°C to 1300°C (32°F to 2372°F) |

±0.05% of rdg ±0.6°C (±1.08°F) |

0.05°C (0.09°F) |

|||

|

W |

1500°C to 2315°C (2732°F to 4199°F) 0°C to 1500°C (32°F to 2732°F) |

±0.05% of rdg ±1.1°C (±1.98°F) |

0.05°C (0.09°F) |

|||

|

R |

300°C to 1768°C (572°F to 3214.4°F) 0°C to 300°C (32°F to 572°F) |

±0.05% of rdg ±0.8°C (±1.44°F) |

0.05°C (0.09°F) |

|||

|

S |

300°C to 1768°C (572°F to 3214.4°F) 0°C to 300°C (32°F to 572°F) |

±0.05% of rdg ±0.9°C (±1.62°F) |

0.05°C (0.09°F) |

|||

|

B |

400°C to 600°C (752°F to 1112°F) |

±0.05% of rdg ±1.7°C (±3.06°F) ±0.05% of rdg ±1.0°C (±1.8°F) |

0.05°C (0.09°F) |

|||

|

Pt100 |

−200°C to +660°C (−4°F to +1220°F) |

±0.1% of rdg ±0.3°C (±0.54°F) |

0.02°C (0.036°F) |

|||

|

JPt100 |

−200°C to +510°C (−4°F to +950°F) |

±0.1% of rdg ±0.3°C (±0.54°F) |

0.02°C (0.036°F) |

|||

|

Buffer memory |

200k data |

|||||

|

Warm-up time |

30 minutes or more |

|||||

|

Power consumption |

1.2 W or less |

|||||

|

Ambient operating temperature |

0°C to +40°C (32°F to 104°F) |

|||||

|

Ambient operating humidity |

35 to 85% RH (no condensation) |

|||||

|

Weight |

Approx. 230 g (including approx. 100 g for the OP-51582 (NR-TH08 terminal block)) |

|||||

Scroll

We’re here to provide you with more details.

Reach out today!

Reliability During Temperature Data Collection

Since temperature data is generally collected over a long time, the reliability of data collection is an important factor in selecting a temperature data logger.

Operation at an Unexpected Power-off

When the power supply is turned off unexpectedly (such as due to an instantaneous drop in the power supply), it would be a big problem if the data you have measured so far is lost. To avoid this problem, select a temperature data logger that can protect the collected data, even in cases such as this.

The KEYENCE NR Series significantly improves the reliability of measured data saving with our unique algorithm and supercapacitor-based micro UPS circuit. This improved reliability ensures complete data saving to the SD card even if an unexpected power-off occurs. The NR Series features a highly reliable design that reduces the risks of data loss and file system damage.

Operation at Power Supply Recovery

It would be inconvenient if, after a power-off due to a problem such as a power supply disconnection, your measurement remains stopped even after the power supply recovers. This issue can be prevented by selecting a temperature data logger capable of automatically starting collection at power supply recovery.

The KEYENCE NR Series is equipped with an auto-start at power-on function. When this function is set to ON, data collection is automatically started at power-on.

Large-Capacity Memory

Collection of data for a long time leads to a huge volume of data.

Hence, select a recorder equipped with large-capacity memory or a recorder capable of recording data into external memory.

The KEYENCE NR Series is compatible with a 16 GB SD card.

As shown in the table below, this product enables you to collect data without worrying about the remaining memory capacity, even during long-time measurements.

| Sampling cycle | Sampling frequency | Collection period |

|---|---|---|

|

Sampling cycle

1 μs

|

Sampling frequency

1MHz

|

Collection period

1 hr 30 min

|

|

Sampling cycle

10 μs

|

Sampling frequency

100kHz

|

Collection period

15 hr

|

|

Sampling cycle

100µs

|

Sampling frequency

10kHz

|

Collection period

6 days 4 hr 30 min

|

|

Sampling cycle

1ms

|

Sampling frequency

1kHz

|

Collection period

61 days 20 hr 30 min

|

|

Sampling cycle

10ms

|

Sampling frequency

100Hz

|

Collection period

618 days 12 hr 30 min

|

|

Sampling cycle

100ms

|

Sampling frequency

10Hz

|

Collection period

6185 days 4 hr 30 min

|

|

Sampling cycle

1s

|

Sampling frequency

1Hz

|

Collection period

61851 days 20 hr 30 min

|

* Calculated by assuming a 15400 MB data area.

* All calculated with the number of channels set to 1.

* Be sure to use a genuine SD card from KEYENCE.

* For the NR-EN16, a collection period of approximately 60% is assumed.

* For the NR-C512, a collection period of approximately 30% is assumed.

Get detailed information on our products by downloading our catalog.

View Catalog

How to Process Temperature Data after Collection

Collected temperature data is meant to be analyzed.

In addition to measurement functions, important factors in selection also include how easy it is to create reports and similar factors, such as whether the necessary analysis functions are provided.

Easy Report Creation

Ultimately, the collected temperature data is meant to be summarized in a report for analysis. It would be desirable if you could minimize the time spent creating reports, thereby enabling you to focus on data analysis. For this purpose, select a temperature data logger that is highly compatible with PCs (that allows for easy report creation).

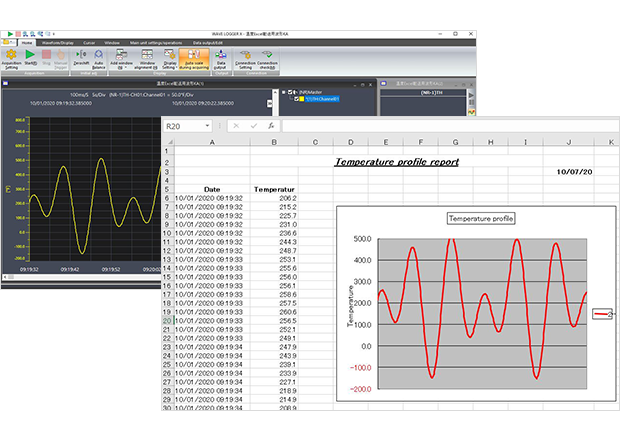

The KEYENCE NR Series is equipped with a real-time Excel transfer function that helps you create reports. At the same time that data is collected, it is directly written into the regular Excel format you usually use. After collection is completed, a report is automatically created, thereby making it easy for you to edit the data or create another report.

Curious about our pricing?

Click here to find out more.

What Are Temperature Data Loggers?

Temperature data loggers such as KEYENCE NR Series, also known as temperature data loggers, are specialized devices used to monitor and record temperature data over some time. This data is subsequently stored and processed on the device and made available for further analysis and interpretation.

These devices, when paired with adequate sensors, can be used to monitor and record temperature data of virtually any object, save for gases. They’re most commonly used in a variety of applications that include perishable goods and/or those applications that demand strictly and precisely controlled temperature environments.

Temperature data loggers are typically small, compact, and battery-powered for easier portability and reliability. They’re usually composed of a main computing unit, one or more temperature sensors, and an internal memory for recording temperature data over time.

It’s important to note the importance of these devices over a wide range of industrial applications, in which temperature monitoring is an essential component of maintaining product quality—at any point during the production and logistics phases.

Get detailed information on our products by downloading our catalog.

View Catalog

Different Types of Data Recorders

All data recorders are the same, as they perform the same function—only the external design and extra features might be different. Modern data records are quite compact and portable and can be used with a wide variety of input transducers, which makes them nearly universal for measuring and recording the temperatures of solids and liquids.

As such, they’re typically categorized by sensor type into thermocouples, thermistors, resistance temperature detectors, and infrared sensors.

Thermocouples are incredibly common in metrology, as they’re capable of operating in a vast temperature range from -200°C to 1700°C. Thermistors, on the other hand, have a non-linear response to temperature change, which makes them perfect for precise temperature measurements in a limited temperature range. Resistance temperature detectors, also known as RTDs, are incredibly accurate over a reasonable temperature range, and the same applies to infrared temperature sensors—the latter has to be calibrated for a specific range for higher accuracy.

Discover more about this product.

Click here to book your demo.

What Is the Science of Measuring Temperatures Called?

The science of measuring temperature is called thermometry, and it’s a really important branch of metrology with vast applications across scientific research and practical, everyday applications. Thermometry is a rather dynamic field that’s completely based on the understanding of temperature and the physical properties of objects.

The purpose of thermometry is to determine the relative thermal properties of objects and environments and compare them to a thermal reference point, 0°C and 20ºC, which is crucial for many everyday processes in both personal and industrial applications.

Besides just measurements, the field also includes the development, calibration, and use of various measuring devices ranging from traditional mercury- and gallium-filled to modern and digital thermometers—such as resistance temperature detectors, thermistors, and infrared sensors.

Given that temperature measurements play a crucial role in controlling diverse processes, ensuring the precision and accuracy of equipment and metrology methods becomes the foremost priority in thermology. That’s why researchers in thermometry constantly engage in improving the methodology of thermometry and the sophistication of measuring equipment.

Ready to elevate your temperature measurements, taking your precision and accuracy to the next level? Contact us to learn more about KEYENCE's range of advanced equipment.

We’re here to provide you with more details.

Reach out today!

![Temperature Measurement Basics [Temperature Recorder Selection Edition]](/img/asset/AS_118849_L.jpg)