- Barcode Reader.com >

- Applications by Product

Applications by Product

Examples of Our Powerful and Versatile Barcode Readers

-

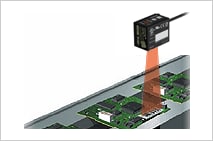

Serial control of printed-circuit boards

The SR-700 can stably read different colored boards due to its multiple parameter banks and ability to choose the correct one.

-

Traceability control of HDD parts

The space-saving SR-700 can read codes on HDDs, automatically controlling the manufacture / inspection records of all inventory.

-

Automatic reading of Kanban

The SR-700 reads 2D codes for Kanban applications. Thanks to its excellent angle characteristics, it can even read inclined codes.

-

PC board : Traceability

The SR Series can read barcodes printed on PC board regardless of vibration or irregular code location.

-

Wafer carriers management

Thanks to the AGC function, the BL-1300 can reliably read PFA-coated barcode labels even at extreme angles.

-

Verification of test tubes

With its compact body and high speed reading capability, the BL-1300 can easily read the barcodes on medical test tubes.

-

Wafer Carriers

The Auto Gain Control function (AGC) ensures that even Teflon® coated bar codes are reliably read.

-

Wafers

A stable reading is ensured even for bar codes on ceramic labels or those written by a laser marker.

-

Automatic sorting

Reliably reads barcodes printed on cardboard boxes of different sizes or those with low print contrast.

-

Engine block

The Auto Gain Control function (AGC) guarantees a reliable read even if the bar code labels are dirty or dusty.

-

CRT production process

Code reading is reliable even when barcodes are on curved surfaces due to geometric correction.

-

Medical applications

Despite the ultra-small body, just half the size of a business card, the BL-180 Series offers a wide reading range. It can reliably read bar codes on specimen containers.

-

Shelf management

The compact body can be mounted easily anywhere on the shelf.

-

Automatic slip reading

Item slips are automatically read when they are inserted in the case. Workability is greatly improved.

-

Simple Changeover

The BL-N70 Series and DV-90 ID controller can simplify product changeover and eliminate the need for complex PLC programming.

-

Component Assembly

Using the BL-N70 Series barcode data can be sent directly to a PLC or DV-90 to determine correct component selection.

-

Ensuring Proper Mixture of Chemicals

BL-N70 and DV-90 can scan up to 3 different batch components to match a single recipe. An alarm indicates incorrect chemicals.

-

Package Check

Preventing different products from being mixed in a packaging machine.

-

Assembly Instructions

Giving assembly directions in an assembly process.

-

Checking for the mixing of different products

The bar code data is compared with the preset data, and a "matched" or "unmatched" signal can be output without a PC.

-

Changeover

The bar code data can be sent directly to a PLC.

-

Operator Instructions

The bar code data can be sent directly to a PLC without any complicated communication programming.

- PLEASE

CONTACT US -

Ask an Expert

Ask an Expert Price Inquiry

Price Inquiry Experience Demo / Test

Experience Demo / Test Free Trial Unit

Free Trial Unit 1-888-KEYENCE

1-888-KEYENCE

( 1-888-539-3623 )