Deflection and Decentering

When choosing a sensor to measure runout or deflection, you'll need to consider both accuracy and speed because the sensor needs to be responsive enough to capture the change. You can browse some options below, or request a free consultation with a local specialist.

High-speed thrubeam sensors can measure runout and ovality of rotors accurately and repeatably.

High-speed optical micrometer

LS-9000 series

Measure drill bit diameter, wear, and eccentricity with a single 2D thrubeam sensor.

Telecentric Measurement System

TM-X5000 series

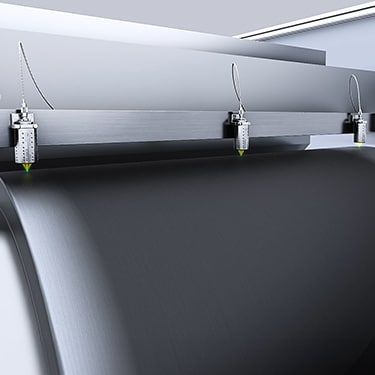

Measure roller runout using confocal sensors with high stability on reflective surfaces.

Confocal Displacement Sensor

CL-3000 series

2D silhouette-based measurements make it possible to accurately inspect the shape of the target. This provides a reliable solution for both multi-point inspection (such as coaxiality) or runout measurement.

Telecentric Measurement System

TM-X5000 series

Thermal expansion and runout of rolls for electrode shaping can be measured. The high heat resistance allows for highly accurate measurement even of rolls heated to 200°C.

Confocal Displacement Sensor

CL-3000 series