Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

The Evolution and Impact of Machine Vision in Factory Automation

Automation has become an unavoidable trend for achieving low costs and high quality in manufacturing. From simple tasks to assembly and inspection processes that require advanced techniques, this work is rapidly being automated, and productivity has come to rise to levels greater than before.

In this resource, we will explore a brief history of machine vision, as well as the various benefits and applications.

What Is Factory Automation?

Factory automation is the use of machine equipment, control systems, and software to complete industrial tasks with little to no human intervention.

Importance of Machine Vision in Factory Automation

Aside from automating many routine and manual tasks in manufacturing plants, machine vision systems help with quality control, process optimization, data collection with analysis, traceability, and safety efforts.

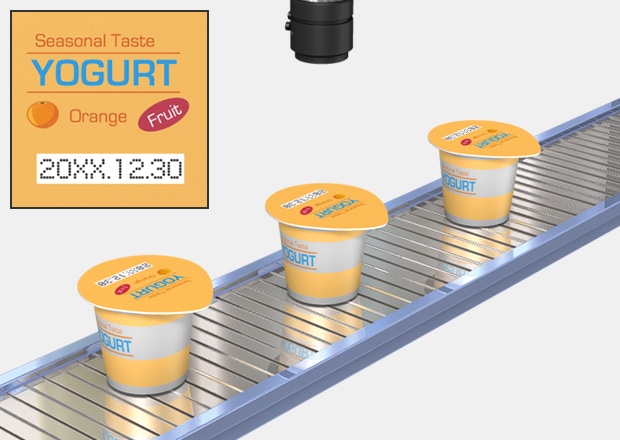

For example, machine vision systems used in product packaging inspections help identify defects, dimensional inaccuracies, and flaws like scratches in products, ensuring only high-quality items are delivered to customers.

High-quality cameras, image processing filters, vision software, and many other components help machine vision technology capture and process image data for processing and defect identification.

Applications of Machine Vision in Factory Automation

Machine vision systems are used in different aspects of today’s automation-focused manufacturing processes:

- In robot guidance, machine vision is used to direct robots in tasks such as picking and placing items, welding, and assembly.

- In quality control, vision systems are deployed to check and monitor defective items and other deviations from production standards.

- In packaging and labeling efforts, machine vision is used to read barcodes and QR codes. This application is required to track and identify products during recalls, returns, and internal product documentation.

Traditionally handled by human workers, these efforts become machine-automated, leading to greater accuracy and production efficiency.

Advances in Machine Vision and Factory Automation

Many efforts predate today’s advanced machine vision systems. For example, in the 1950s, psychologist James J. Gibson introduced the concept of optical flow. Optical flow is a machine vision technique for tracking movement by identifying pixel patterns between frames. It's commonly used in sports broadcasting to track players on the field or court or to identify objects as they move along a conveyor belt. In response, researchers started to create mathematical models for computing optical flow on a pixel-by-pixel basis.

In the 1960s, Larry Roberts’ PhD thesis at MIT explored the possibility of extracting the 3D geometry of objects from 2D representation. This prompted further research and developments in stereo vision and other 3D techniques.

In the late 1970s, through MIT's Artificial Intelligence Lab’s machine vision course, David Marr discovered a framework for analyzing raw image data and gradually building up a more abstract scene understanding. This framework is known as the bottom-up approach to scene understanding, inspiring more subsequent machine vision research.

The trade group Automated Imaging Association (AIA), founded in 1984, pioneered the movement to promote the use of machine vision technology and a platform where industry professionals can network and share knowledge.

By the 1990s, vision systems started to become commonplace, with many manufacturers adopting them in their operations.

Modern machine vision systems are well-formed and capable of handling simple to complex industrial tasks. They offer incredible speed and accuracy. To meet the ever-growing automation needs of industries, machine vision is continuously evolving for even greater flexibility.

Step Into the Future of Factory Automation With Our Advanced Machine Vision Systems

For decades, KEYENCE has provided futuristic vision system solutions for manufacturing lines. These vision solutions are designed for industrial plants and lines looking to automate manual tasks or upgrade their factory automation systems.

Some of the industries using vision systems from KEYENCE are medical, pharmaceutical, food and beverage, and automotive. Our systems are equipped with powerful, high-res cameras, vision software, AI capability, and enduring hardware enclosure.

For more information on how our machine vision systems can help boost your factory automation solutions, contact us today.

Related Downloads

![A Technical History of Image Processing Vol.1 [Camera]](/img/asset/AS_46814_L.jpg)

An Introduction to the History of the Camera and the Image Processing Advancements Achieved, From the Birth of the Camera to the Current Digital Cameras.

![A Technical History of Image Processing Vol.2 [Lenses]](/img/asset/AS_46815_L.jpg)

An Introduction to the History of the Lens from Its Origins Over 2000 Years Ago to the Historic Changes in Materials & Designs.

![A Technical History of Image Processing Vol.3 [Illumination]](/img/asset/AS_46816_L.jpg)

An Introduction to the History of Illumination from the Early Days of Open Fires and Torches to the Advanced Technological Developments with LED Lighting Today.Back-issues of This Series Are Currently Available to the Public as Well.

![A Technical History of Image Processing Vol.4 [Factory Automation & Image Processing]](/img/asset/AS_46817_L.jpg)

We Have Compiled Information That Will Show You How FA Has Come to Change. Feel Free to Take a Look at These Materials.Back Issues Are Also Available!

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

![A Technical History of Image Processing Vol.5 [Traceability]](/img/asset/AS_52287_L.jpg)