Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

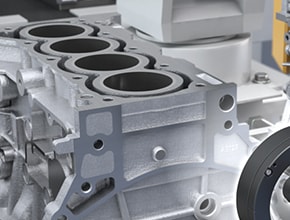

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

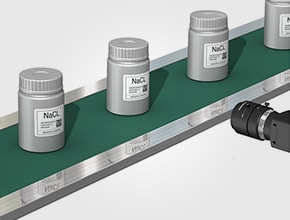

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

What is Machine Vision?

Machine vision, or computer vision, is a technology that enables computers to analyze and interpret visual data from images or videos. It’s an automated system designed to "see" and understand surroundings to perform tasks.

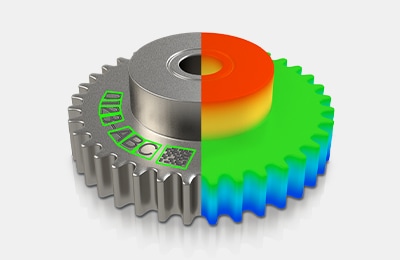

These systems use high-resolution cameras and algorithms to analyze data like shape, color, texture, and size. They detect patterns, trigger actions, and perform advanced tasks such as 3D modeling, motion tracking, and object recognition.

This technology offers diverse applications of machine vision systems across industries. In manufacturing, they optimize automated inspection and quality control. In healthcare, they support medical imaging and diagnostics, and for self-driving vehicles, they enhance object detection and navigation.

How Does Machine Vision Work?

Machine vision mimics the human visual system using cameras for image capture and advanced software for interpretation. It consists of four key components: lighting, optics, image sensors, and processing algorithms. Each element is crucial for capturing high-quality images and accurate interpretation.

Lighting

Lighting is crucial in industrial machine vision, affecting image quality, contrast, color fidelity, and texture. Proper lighting ensures images have enough contrast and detail for accurate analysis by the system. Types of lighting used include ambient, area, backlights, ring lights, and infrared.

Optics

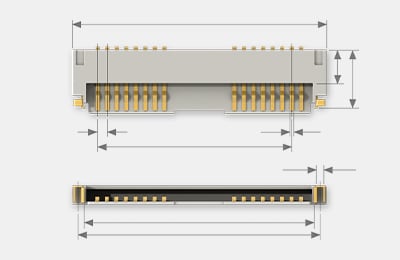

The second component of a machine vision system is optics, which includes lenses or mirrors that focus light onto the image sensor. Optics selection affects the field of view, focal length, and depth of field. A larger field of view captures more data at once, while a smaller one offers higher magnification but less information per frame. Focal length dictates the detail visible, and depth of field pertains to the range of distances in focus.

Image Sensors

Image sensors are electronic components that act as the visual interface of a machine vision system, converting light into electrical signals processed by algorithms to create images. The two main types are complementary metal-oxide-semiconductor (CMOS) sensors and charge-coupled devices (CCDs). CCDs are more sensitive and faster, while CMOS sensors generally offer better image quality.

Processing Algorithms

The final component of a machine vision system is a suite of processing algorithms for analyzing images and extracting valuable information. These use mathematical techniques like pattern recognition, edge detection, and segmentation to identify objects, measure dimensions, detect defects, or make decisions based on criteria. The complexity varies with the application of the machine vision system and desired outcomes.

We’re here to provide you with more details.

Reach out today!

The Benefits of Machine Vision

Machine vision technology uses cameras, computers, and software to automate visual tasks in industrial settings. It offers significant benefits to manufacturing, such as improved product quality, increased efficiency, reduced labor costs, and minimized waste.

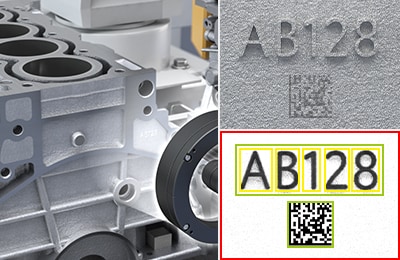

- Improving Product Quality: Manufacturers can detect minor defects during production, allowing for real-time adjustments and reducing the number of defective products.

- Increased Efficiency: As machines take over repetitive visual inspection tasks, production becomes more efficient and consistent, reducing human error and improving accuracy.

- Reduced Labor Costs: Machine vision automates manual tasks, allowing workers to focus on complex tasks needing human decision-making.

- Minimized Waste: Real-time visual feedback allows machines to adjust during production, minimizing scrap and conserving time and resources.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Industries That Use Machine Vision

There are many industries using machine vision, with applications broadening as technology advances and becomes more cost-effective. From automotive manufacturing to logistics, it demonstrates value in enhancing efficiency, accuracy, and productivity across various sectors. Below is a closer look at how machine vision is being utilized.

Discover more about this product.

Click here to book your demo.

Applications of Machine Vision Systems

Machine vision system applications have transformed how industries handle inspection and quality control. Their rapid image capture, data analysis, and decision-making capabilities have made them essential in many industrial applications:

See the benefits firsthand by signing up for a free trial now.

Free Trial

Latest Machine Vision Technologies

Pattern Projection Lighting

Simultaneous 2D and 3D imaging for all standard vision applications.

LumiTraxTM Lighting

Directional lighting enhances height features and reduces glare, while minimizing the effect of ambient light.

Multi-Spectrum Lighting

Versatile lighting with 8 available colors to account for part variation with LumiTraxTM compatibility in all colors.

LED Lighting

High-intensity lighting to ensure high quality image capture every time.

3D Vision-Guided Robotics

Automated, high performance 3D bin picking. Quick and easy to deploy with Auto-Calibration, Robot Path Planning, and Picking Simulator.

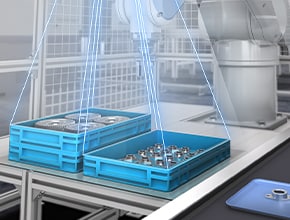

2D Vision-Guided Robotics

Machine vision systems for pick and place applications, with direct connection and automatic calibration for most major robot manufacturers.

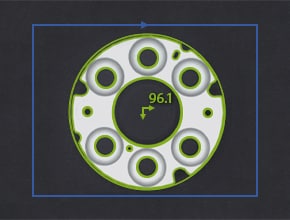

Inline 3D Cameras

High-accuracy appearance and dimension inspection for products and materials of all types.

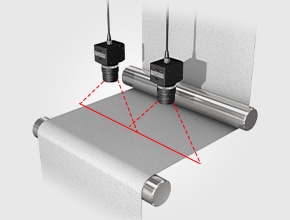

Line Scan Cameras

High-speed cameras for inspection and defect analysis on large parts, continuous webs, and cylinders.

Curious about our pricing?

Click here to find out more.

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace