Laser Marking Systems / Laser Markers

Laser Etching

Laser etching machines are revolutionary tools that open up amazing possibilities in creating, crafting, and even manufacturing objects with highly intricate and detailed designs. By harnessing the power of laser technology, many industries are transforming a wide variety of materials, ranging from organic products like wood to metals, into breathtaking pieces of art or useful industrial products.

In the following, we will learn about laser etching machines, the materials used, common laser etching applications, and the types of laser etching solutions KEYENCE provides to help improve processes.

What is Laser Etching

Laser etching is a process of using a laser to remove material from a surface. By running the laser beam along the desired path, the workpiece is etched in the desired pattern. The etching depth and type of marking can also be controlled by changing the laser parameters. It can be used for a variety of purposes, including engraving, cutting, and marking. Laser etching is a very precise process, and it can be used to create detailed designs or patterns on a wide range of materials, including glass, wood, metal, and plastic.

Laser etching is becoming increasingly popular for a number of reasons. First, it is a very efficient and cost-effective way to produce high-quality results. In addition, laser-etched designs are highly resistant to wear and tear, making them ideal for products that will be used frequently.

The combination of an adaptable design, a non-contact approach, and improved results makes the technology a contender to alternative methods. Aside from the technology’s capabilities, it’s essential to look at it from a competitive standpoint.

In many ways, laser etching is a win-win for the manufacturer, the end user, and everyone in between. It delivers benefits to individual parts, employees on the ground floor, and the consumer. Considering the many materials laser etching machines are compatible with, it has become a no-brainer in the world of modern manufacturing.

Steel etching

Aluminum etching

Glass etching

We’re here to provide you with more details.

Reach out today!

Laser Etching Process

During the laser etching process, the laser beam melts the material, vaporizing it or evaporating it. The process is quick and precise, making it ideal for creating high-quality marks on products.

The first step in creating a laser-etched product is to create a design. This can be done using software such as Adobe Illustrator or Photoshop. Once the design is complete, it is saved as a vector file. This file is then imported into the laser etching machine. The machine will read the file and follow the vectors to create the desired shape or design.

The next step is to select the material that will be used for the project. This can be anything from wood to metal to glass. Once the material is selected, it is placed in the machine and secured in place. Then, the machine settings are adjusted according to the type of material being used and the desired results.

Finally, the laser is turned on and directed at the material. The beam will etch the material, following the path of the vector file. As the laser moves over the material, it will gently remove small amounts of material, creating text, images, or patterns on the surface. Laser etching is a quick and easy way to create high-quality products with a unique look.

Discover more about this product.

Click here to book your demo.

Key Features of Our Laser Etching Machines

As a whole, Laser marking systems are an extremely adaptable technology that can work with a long list of materials and product types. This even translates into the realm of laser etching or laser engraving machines, but it depends on the type of technology, technique, and settings you apply.

Whether you’re focused on fabric laser etching or hard metals, here are a few key features of KEYENCE laser etch machines:

- Customizable depth control

- Extremely efficient beam delivery system

- Impressive automation capabilities

- Unmatched precision

- Data-driven analytics for quality control

- Lower maintenance requirements

The variations in different types of laser heads and their material use cases mean the technology can be applied to a seemingly endless list of industries. Due to this fact alone, many manufacturers are considering making the switch from traditional production techniques and associated technologies. Understanding the true depth of applications behind a laser engraving etching machine can open a whole new world of business opportunities.

We’re here to provide you with more details.

Reach out today!

Applications of Our Laser Etching Machines

Laser etching has continued to play a pivotal role in manufacturing and product design. This process is providing precision and high-contrast markings on many types of materials. This, along with the fact that it enhances product quality, aesthetics, and traceability, makes it an attractive option. The benefits provided, along with the cost-effectiveness, have led to many use cases across a variety of industries.

In the automotive industry, laser etching is necessary, as it is used for marking vehicle identification numbers (VINs) and labeling all types of components. This ensures traceability and quality control, which are essential in this sector where precision and safety are critical.

Gear

Engine block

Similarly, the aerospace industry relies on laser etching to mark specific components, such as turbine blades and connectors. Marks include part numbers and serial information, maintaining rigorous quality standards.

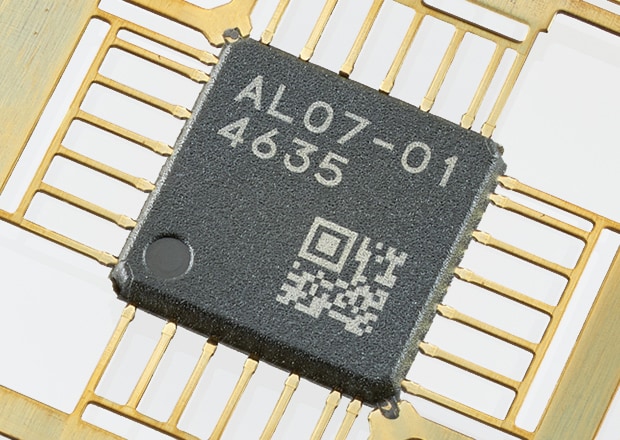

Take a look at the electronics in your household, and you can find products that were laser etched. As an example, most laptops are etched with logos, brand names, serial numbers, and more. This process is invaluable for printed circuit board labeling and marking small electronic components with precision. It is also a popular choice for creating logos, serial numbers, and branding on consumer electronics.

Epoxy package

Crystal oscillators

In the medical device industry, laser etching helps with marking surgical instruments, implantable devices, and medical packaging. These etchings provide legible, tamper-resistant information like lot numbers and expiration dates.

Steel instruments

Medicine bottles

As one last example, jewelry and luxury goods designers also benefit from laser etching. They use it for intricate designs and personalized messages on precious materials. For example, a jeweler can laser etch a wedding ring with floral patterns, initials, or even a wedding anniversary date. These etchings add both aesthetic value and authenticity to products.

It should be highlighted that many of these examples helped to pioneer laser etching and bring it to the world stage. However, many other industries have yet to experience the benefits of modern laser etching technology. While most are familiar with the process of chemical etching, this is quickly becoming seen as outdated compared to what a laser machine for etching can accomplish.

While there are plenty of current applications, you’ll find there’s still room for innovation in using this technology with existing and new products alike. As you see, laser etching continues to prove itself as an indispensable tool in manufacturing.

Curious about our pricing?

Click here to find out more.

Laser Etching Machine

A laser etching machine is the force and brains behind the process. These machines are widely used in manufacturing and throughout many of the top industries. Although a laser etching machine can be manufactured with different options and features, some have a few key benefits over others.

KEYENCE offers a variety of laser etching machines that can be used to improve processes and create designs or patterns on a variety of materials. Our laser etching machines are available in numerous sizes, wavelengths, and power levels to meet the needs of any business or application. We are dedicated to supplying laser etching machines that are easy to use and offer a variety of features to meet the needs of any business.

KEYENCE’s laser etching machines and laser marking systems are not only innovative but reliable, bringing you the latest in marking technology. Contact us today to learn more about laser etching equipment and how it can improve your operations.

3-Axis Hybrid Laser Marker MD-X Series

The 3-Axis Hybrid Laser Marker MD-X Series combines the strengths of a conventional fiber laser with those of a YVO4 system. Fiber lasers are designed for long service life and high output power, granting high-speed marking and system longevity. YVO4 lasers are designed for high quality, delicate marking, and increased depth of focus for flexibility. Together, these lasers create the MD-X with high peak power and a short pulse laser.

Combining these two laser types creates a system that is powerful enough to meet stringent cycle time requirements but also robust enough to achieve quality markings on any metal. Paired with KEYENCE's 3-Axis control, full field auto-focus, and automatic position adjustment, the MD-X Series is ideal for any metal marking need.

3-Axis UV Laser Marker MD-U Series

The 3-Axis UV Laser Marker MD-U Series is the world's first 3-Axis UV laser marker. The shorter wavelength (355 nm) allows for cold marking and processing that can be performed with minimal heat stress, so it’s often referred to as "damage-free.” The KEYENCE MDU is internally air-cooled and numerous patents contribute to this unit's industry-leading lifetime.

The MD-U's shortened wavelength and resulting increased absorption rate arm it with best-in-class versatility of material suitability. Dramatic increases in both contrast and marking quality, reduced surface damage, and the ability to overcome pesky material inconsistencies make the MD-U the most capable laser etching machine available.

Get detailed information on our products by downloading our catalog.

View Catalog

Technical Specifications of Laser Etching Machines

Understanding the capabilities of etching laser machines is helpful, but grasping the technical specifications is just as crucial. Not to be confused with laser etching vs engraving, etching does consider the use of different types of laser mediums. Even more so, the type of laser used and its specifications can come with quite a few unique details about the end results.

At a glance, some of these technical specifications include:

- Laser types such as CO2, UV, and fiber designs

- Power output and marking speeds can vary

- Software-driven control systems

- Precise and effective beam quality

No matter which angle you look at it, whether it's laser etching machine cost, maintenance, or output capability, the technology soars with flying colors. It comes down to understanding how it all works and where you can integrate it into your current production needs.

Discover more about this product.

Click here to book your demo.

Enhance Your Manufacturing with KEYENCE Laser Etching Machines

For those who are ready to take their manufacturing processes and expand, laser etching machines can help you get it done. It’s helpful to work alongside the experts to ensure you get the right laser technology for the job. KEYENCE is just a click away with the answers you need to upgrade your manufacturing processes, impress your clients, and expand your market reach.

We’re here to provide you with more details.

Reach out today!

Related Downloads

2D codes have become a near-universal standard for traceability. This must-read document covers everything from code scanning principles, laser installation, predictive maintenance, and more.

Some laser marking applications require integration with multiple devices. KEYENCE provides a total marking solution, from X/Y stages and indexing systems to head traversal systems. Learn more in this brochure.