Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Coding on Metal Materials

Coding on metal parts is vital to ensure traceability and quality control. The MK-G Series has a state-of-the-art automatic ink particle sensing system, ensuring the printer can maintain the best possible ink conditions and provide stable and high-quality printing on metal materials.

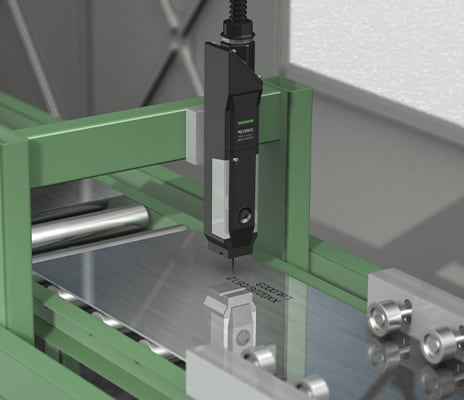

Lot/Part Number Coding on Metal Components

The MK-G Series is specifically designed for lot/part number coding on metal components. With their compact print head, they can easily be integrated into any production line, offering a flexible layout and installation. The printers use non-contact printing technology, ensuring that there is no damage to the metal surface during the marking process.

- Panels and Faceplates

- Flanges and Couplings

- Tubing and Piping Sections

- Brackets and Mounting Plates

- Handles and Levers

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Metal

Harsh Environments

Extreme temperatures and chemical exposure can cause traditional printing methods to fade, complicating tracking and identification. KEYENCE CIJs are built to endure these harsh conditions, ensuring clear and reliable marking.

High-Speed Lines

Steel materials are often manufactured on high-speed lines, posing challenges for consistent coding on construction and building materials. The MK-G Series delivers high-quality printing, ensuring reliable coding on metal parts for traceability.

Compliance with Industry Standards

Building materials must meet regulations for part and lot numbers, requiring clear and permanent markings. The MK-G Series exceeds these standards with automatic ink-particle optimization technology for stable printing.

Maintenance

Traditional printing solutions need frequent maintenance. The MK-G Series automates and simplifies this process, saving time and labor costs for uninterrupted production.

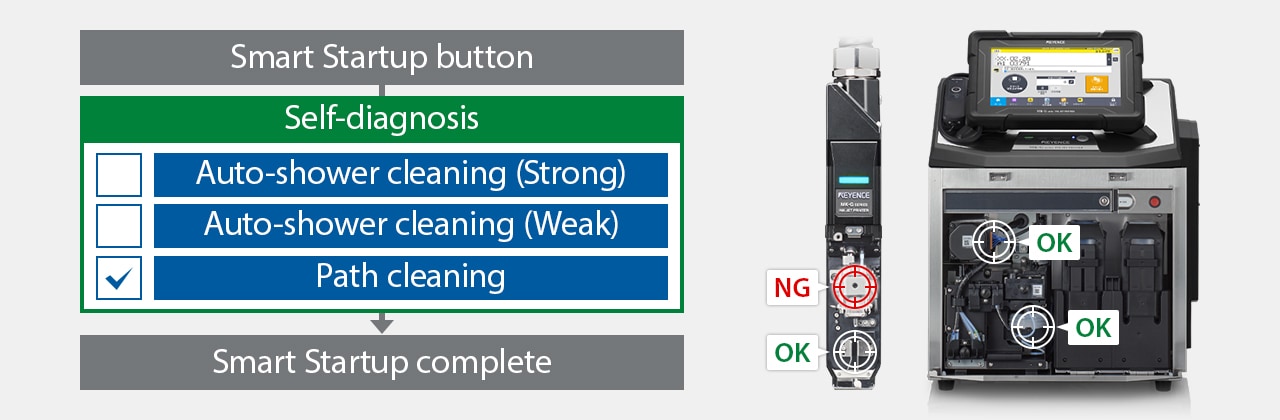

Self-Diagnosis Followed by Automatic Cleaning When Necessary

INDUSTRY FIRST Smart Startup

To start the MK-G Series, simply press the Smart Startup button. The printer will automatically obtain the device status and select the necessary cleaning method. Cleaning is performed only when required and the minimum amount of solvent is used, significantly reducing running costs.

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

CIJ for Metal and Steel Industry

Continuous inkjet printers are essential in the metal and steel industry, providing superior coding and marking on metal parts. With high-speed marking capabilities, they produce clear and durable codes on even the most challenging metal surfaces. Engineered with user-friendly interfaces and intuitive layouts, CIJs for industrial manufacturing reduce training needs and simplify operations. Automatic and intuitive troubleshooting features contribute to maintaining uninterrupted performance.

Industrial inkjet printers

like the MK-G Series are designed to boost production efficiency and ensure consistency in rigorous industrial environments, all while adhering to strict quality and compliance standards.

Both the head and the console comply with MIL Standard drop evaluation requirements.

INDUSTRY FIRST MIL Standard-Compliant Drop-Resistant Structure

The head and console—two components often picked up and moved—come equipped with a robust, dedicated jacket. The structure of these devices, as well as the Operation Assist Camera, can withstand accidental drops.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Marking and Coding on Metal Components

Why Is Lot and Part Number Coding on Metal Materials Important?

Lot and parts number coding on metal components ensures traceability, quality control, and compliance to identify track, and recall components efficiently for safety and accountability.

How Does Ink Viscosity Affect Lot and Part Number Coding on Metal Materials?

Viscosity affects flow and adhesion on metal surfaces. High viscosity may lead to poor print quality, while low viscosity can cause smudging.

How Does the MK-G Series Ensure Stable Coding on Metal Parts Despite Temperature Changes?

The MK-G Series uses advanced technology to optimize ink particle conditions, automatically adjusting itself 10 times per second to maintain stability.

How Does the MK-G Series Prevent Ink Dilution During Cleaning to Ensure Reliable Coding and Marking on Metal Components?

A closed-loop ink system minimizes exposure to cleaning solvent. This design maintains consistent ink concentration, ensuring print quality and reliable code and marking on metal parts.

How Does the MK-G Series Simplify Maintenance in Harsh Environments?

The MK-G Series printhead has an IP55 rating, so it's protected from dust, dirt, and debris. It also utilizes a self-diagnosing system, which helps troubleshoot any potential issues in challenging environments.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper