Continuous Inkjet Printers / Case Coder

Coding on Lumber and Wood Products

Coding on lumber & wood products is crucial for efficient tracking and delivery of products, helping to prevent mix-ups. However, it can be challenging due to uneven textures and moisture levels.

The MK-G Series CIJ for industrial manufacturing features non-contact printing and advanced sensors that adjust ink droplet size for clear, precise printing on wood, ensuring legible and durable product codes in varying environments.

Lot/Date Coding on Lumber and Wood Products

Lot and date coding on lumber & wood products is essential for traceability and compliance with regulations. The MK-G Series continuous inkjet printer offers flexible printing options, including sequential numbering, expiration dates, and batch codes, to meet various industry requirements. With its self-troubleshooting capabilities, the printer can also detect and alert for any errors in code printing to prevent costly mistakes.

- Dimensional Lumber

- Timber

- Plywood

- Oriented Strand Board (OSB)

- Medium-Density Fiberboard (MDF)

- Particleboard

- Hardwood Lumber

- Softwood Lumber

- Wood Veneer

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Lumber and Wood Products

Uneven Surface

Lumber and wood products have uneven surfaces, which can hinder lot/date coding on lumber & wood products. The MK-G Series addresses this by using a non-contact method of printing.

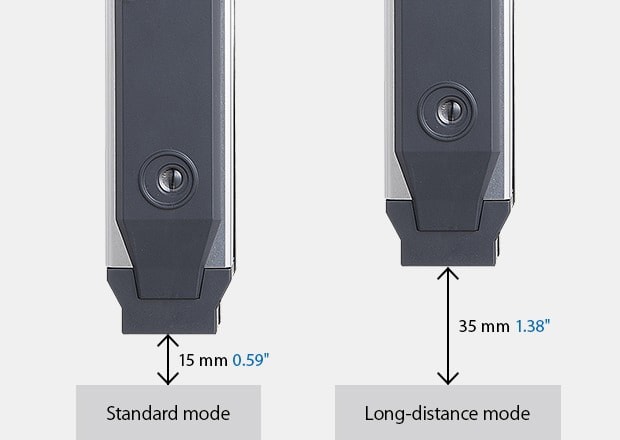

Long-distance mode:

Printing can be performed with the print head located up to 35 mm 1.38″ away from the target. This makes it possible to perform stable marking that isn’t affected by variations in the thickness of printing targets and reduces the risk of print head collision.

Fluctuating Temperatures

Temperature and humidity fluctuations can affect traditional inkjet printers, causing smudged codes. The MK-G Series uses internal sensors to help adjust the ink particles when temperature and viscosity levels change to ensure print quality consistency.

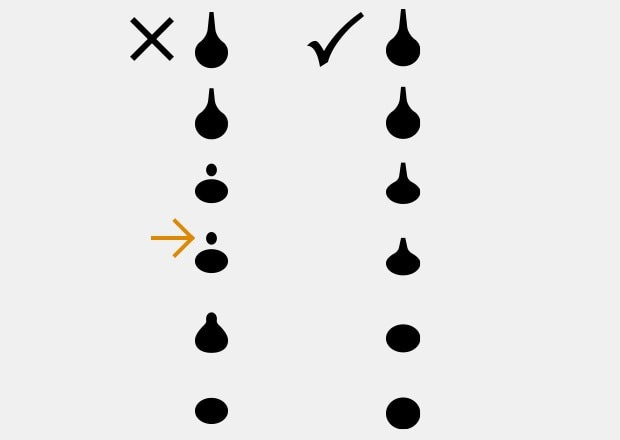

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Automatic ink particle optimization:

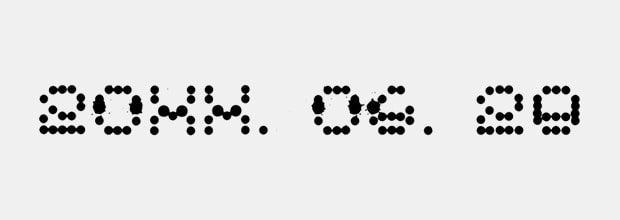

The surrounding environment, temperature, and ink viscosity all have an effect on the condition of ink particles and their suitability for printing. The MK-G Series senses the ink particles 10 times per second, which enables automatic adjustment to ensure the best conditions. This allows the device to provide superior printing at all times, regardless of the environment.

Less-than-optimal state of particles

Optimal particle state

Wood Dust

Lumber production facilities often have high dust levels, affecting printer performance. The MK-G Series features an IP55-rated print head design that keeps dust out, ensuring reliable printing.

Curious about our pricing?

Click here to find out more.

CIJ for Wood Product Industry

Manufacturers in the lumber and wood products industry often struggle with coding due to the absorbent nature of wood, which complicates traditional printing methods. The MK-G Series industrial inkjet printer employs non-contact printing technology to spray tiny ink droplets, producing clear, durable codes on uneven surfaces. It also offers fast printing speeds and can print multiple lines of code simultaneously, making it ideal for high-volume production lines in this sector.

Discover more about this product.

Click here to book your demo.

FAQs about Marking and Coding in the Wood Product Industry

How Does the KEYENCE MK-G Series Ensures Accurate and Durable Coding on Lumber and Wood Products?

The MK-G Series uses continuous inkjet technology to spray tiny ink droplets onto wood, producing clear, long-lasting coding on construction and building materials.

What Is the Role of the Conditioning Tank in Maintaining Stable Marking and Coding on Lumber and Boards?

The conditioning tank is vital for stable coding on lumber & wood products, collecting solvent during the cleaning process to prevent ink dilution and maintain consistent viscosity.

How Does the MK-G Series Handle Rough or Uneven Surfaces When Coding on Lumber and Boards?

The MK-G Series uses advanced technology to spray tiny ink droplets for precise codes on uneven surfaces, and its high-speed printing allows for multi-line coding on lumber & wood products.

Why Is Accurate Lot/Date Coding on Lumber and Composites Crucial for Inventory and Traceability?

Accurate coding and marking on lumber and composites is crucial for inventory traceability, supply chain management, and identifying potential issues for quick resolution.

How Can the MK-G Series Help Reduce Downtime on Production Lines for Coding and Marking Lumber and Wood Products?

The MK-G Series minimizes production line downtime with quick maintenance, fast and easy consumable part replacements, and high-speed printing. It also features automatic cleaning to reduce manual labor and streamline operations.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.