Continuous Inkjet Printers / Case Coder

Coding on Extrusions

Extrusion efficiently produces uniform items like pipes and tubes, but coding on extrusions is challenging. Lubricating oils can cause smudging, and high temperatures may affect code clarity, complicating operations.

The KEYENCE MK-G Series automates maintenance and troubleshooting, simplifying coding on extrusions without the need for technical expertise, reducing the risk of errors even in harsh environments.

Date Coding and Marking on Extrusion Material

The MK-G Series provides durable, fade-resistant printing, making it ideal for challenging conditions. With non-contact continuous inkjet technology, the MK-G Series is designed for continuous operation, perfect for high-volume production and coding on construction and building materials such as:

- Pipes

- Tubes

- Cables

- Framing

- Railings

- Panels

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking Extruded Materials

Extreme Heat

High extrusion temperatures can reduce print quality and increase maintenance. The MK-G Series senses ink particles 10 times per second and adjusts to ensure optimal printing in varying conditions.

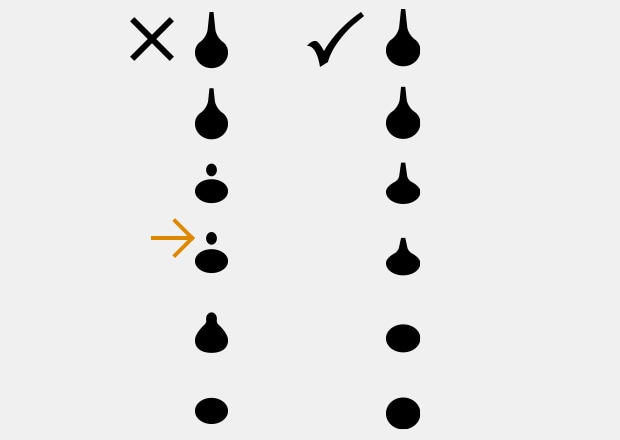

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Eliminate Temperature-Based Printing Problems

Automatic ink particle optimization:

The surrounding environment, temperature, and ink viscosity all have an effect on the condition of ink particles and their suitability for printing. The MK-G Series senses the ink particles 10 times per second, which enables automatic adjustment to ensure the best conditions. This allows the device to provide superior printing at all times, regardless of the environment.

Less-than-optimal state of particles

Optimal particle state

Vibrations

Extruder vibrations can impact code quality, while falling objects may damage printing equipment. The MK-G Series print head and touch console feature durable MIL Standard-compliant construction for reliable vibration and drop resistance.

Durability of Codes

Plastic pipes and cables face harsh conditions. Our MK-10 ink, used in the MK-G Series, delivers clear black printing with a rapid one-second drying time, which prevents smudging.

High-Speed Production Lines

Coding and marking extruded materials is challenging due to high speeds and constant production. The MK-G Series features automatic maintenance, ensuring uptime and consistency.

Curious about our pricing?

Click here to find out more.

CIJ for Extrusion Molding Pipes

Continuous Inkjet Printers technology has transformed the manufacturing of extrusion-molded pipes. Unlike slower, error-prone traditional methods, CIJ offers a faster, more reliable solution, making it the top choice for manufacturers worldwide.

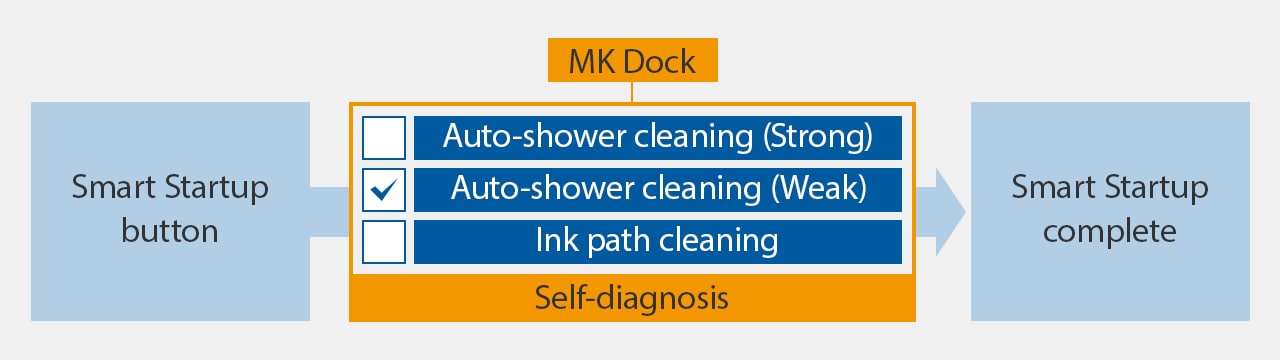

Just placing the print head in the MK Dock starts optimal cleaning of the main head parts.

The MK-G Series CIJ for industrial manufacturing revolutionizes coding on extrusions with its ability to print seamlessly on curved surfaces. Its self-diagnostic features cut labor costs by reducing the need for specialized technicians, while the automatic cleaning system prevents inkjet clogging, ensuring consistent, high-quality printing.

Discover more about this product.

Click here to book your demo.

FAQs about Date Coding in the Extrusion Industry

How Does CIJ Technology Ensure Durable and Legible Coding and Marking on Extrusion Molding Pipes?

The CIJ MK-G Series uses self-diagnostics to detect issues like low ink or print head malfunctions, ensuring reliable coding with less downtime.

How Do the MK-G Series CIJ Printers Ensure Accurate Coding and Marking on Curved or Irregular Extrusion Surfaces?

KEYENCE’s MK-G Series features advanced non-contact printing technology, with sensors monitoring key parameters like temperature, ink viscosity, and droplet size.

Why Is MK-G Series CIJ the Preferred Solution for Coding and Marking Extrusions in Harsh Manufacturing Environments?

The MK-G Series head and controller feature IP55-rated construction for strong protection against dust, water, and other environmental challenges.

How Does CIJ Coding Adapt to the High-Speed Production Lines Used in Extrusion Manufacturing?

MK-G Series CIJ uses fast-drying inks designed for accurate, reliable coding, even at high production speeds.

What Are the Maintenance Requirements for CIJ Coding and Marking on Extrusion Molding Pipes?

The MK-G Series is designed for automated self-maintenance, reducing the need for manual intervention and freeing up operators to focus on higher-priority tasks.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.