Data Acquisition (DAQ)

How to Measure Torque: A Complete Guide

-

Tags:

- Current , Data Acquisition , Voltage

Measuring torque involves specialized tools such as torque sensors and torque transducers, which apply and measure specific amounts of rotational force (torque). These devices provide torque readings by converting mechanical rotation or static systems, such as engines and robotic arms, into electrical signals, which can be displayed digitally and recorded for analysis.

What is a Torque?

Torque is measured by the amount of force it takes to rotate an object about an axis. It is essential to any mechanical system and heavily influences how objects rotate and spin.

When it comes to how to measure pressure, the unit of torque in the international measurement of units (SI) is the Newton meter (Nm). The magnitude of the force and the distance from the axis of rotation heavily influence the torque. In short, the measurement of how much force is applied to an object and how far that forces us from the axis of rotation is torque.

Why Does It Matter?

It is used to define performance, efficiency, and friction coefficients. Torque plays a crucial role in both our everyday activities and complex engineering feats.

- Everyday Life: You apply torque to the doorknob to open the door by rotating it. You also apply torque to the wrench to tighten a bolt and to the pedals to rotate your wheels for your bike on your early morning workouts.

- Engineering: To design engines that are functional and effective, you need to understand the power output, which requires knowledge of how to measure pressure and torque. In the field of robotics engineering, torque is used to control the movement of rotation in the arms and joints of a robot.

- Physics: Understanding rotational motions is pivotal in physics, as it helps explain how levers, gears, and pulleys provide a mechanical advantage.

We’re here to provide you with more details.

Reach out today!

Common Tools and Methods for Measuring Torque

Depending on the specific application and industry, some of the common tools used to measure torque are:

Torque Wrenches: There are several types of torque wrenches:

- Click Type - generates an audible click when the desired rotation or torque is reached.

- Beam Type - A visual indicator to show applied torque.

- Digital Type - Provides precise numerical reading on a digital display.

These are all applied in the automotive, manufacturing, and construction industries.

Dynamometers: Measure pressure and the torque produced by rotating a shaft or machine.

- Static Type - Measures torque while the machine is stationary.

- Dynamic Type - Measures during operation, and the absorption which absorbs and measures torque produced by the machine.

- Transmission Dynamometer - Measures torque transmitted through the shaft or coupling.

Strain Gauges: Measure the deformation of a material that is related to torque. This applies to or is used hand-in-hand with torque transducers to measure the pressure in rotating shafts.

Torque Transducers: These devices convert torque into an electrical signal that can be measured.

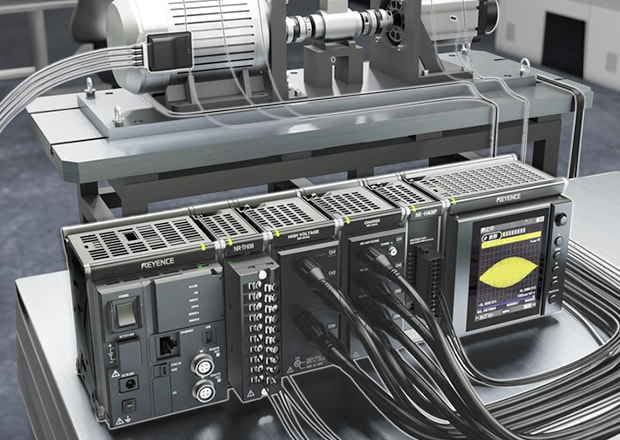

There are several torque devices and methods, but it all depends on the suitability of the required accuracy, range, or application. For this, we recommend the KEYENCE Measurements Data Logger NR-X. Measurements of pressure—in this case, torque —can be used for a wide range of measurements, from simple measurements to multi-aspect, multi-channel measurements.

Get detailed information on our products by downloading our catalog.

View Catalog

Steps to Measure Torque Accurately

These are the steps to measure the amount of torque accurately:

1. Select the Appropriate Method: Thorough research is needed to ensure that the instrument to measure is the right one. After selecting the tool, the method to measure torque depends on the industry, the range of torque, and the accuracy of the measurements you wish to get.

2. Prepare the Equipment: This means ensuring that the machine is properly calibrated, ready to be used in measuring, has been properly attached, and all sensors are working perfectly. Ensure that there are no environmental factors, such as noise or vibrations from other equipment, that may disturb the accuracy of the reading.

3. Apply the Torque: The torque must be applied in a controlled manner. Carefully avoid sudden or excessive forces and apply them in the correct direction.

4. Record the Measurements: This entails using the manufacturer’s guidelines. To get precise and reliable torque measurement, KEYENCE measurement DAQ systems have accurately provided high-performance and versatile solutions for various measurement applications.

5. Analyze Data in the Correct Unit of Measurement: After getting your precise calculations from the torque, analyze the patterns, trends, and anomalies. Ensure to also calculate it in the correct unit, the Newton-meter (Nm).

Torque Measurement Solutions and Applications

The solutions for torque measurements vary per application:

- Rotary Torque Sensors: These are applied in the automotive industries, wind turbines, electric motor performance, and so forth. The rotary sensors are used to measure the force of the torque in rotating systems such as motors and engine output shafts. They provide real data to ensure the system is operating within safe parameters.

- Reaction Torque Sensors: Reaction torque sensors measure torque in static or non-rotating applications where the shaft is stationary. They are applied to tighten torque in assembly lines and machine calibration.

- Contactless Torque Sensors: As the name implies, they only use magnetic or optical principles to measure the torque. It is accurate and even better for systems.

- High Speed: Used on high-speed machines like jet turbines.

The ultimate solution is the KEYENCE torque measurement data acquisition system, which provides eight different measurement units. This series can be used for a wide range of measurements, from simple measurements to multi-aspect, multi-channel measurements.

The compact size makes it possible to carry the device directly to the measurement site, eliminating the need for storage space. The software is also easy to set up and use right away, even for first-time users. Collected data can be exported to Excel with just one click.

Discover more about this product.

Click here to book your demo.

Industries That Rely on Accurate Torque Measurement

Accurate torque measurements are crucial in various industries, ensuring the proper function and efficiency of mechanical systems. Here are some of the industries that rely on precise torque control:

- Automotive: Assembly of vehicle parts

- Manufacturing: Assembly lines

- Aerospace: Jet engines, turbines

- Energy: Turbines for hydroelectric energy

- Robotics: Robot arms and joints

- Medical: Medical devices like surgical robots and prosthetics

Enhancing Efficiency with Torque Measurement

To improve the accuracy of torque measurements, real-time torque monitoring with a proper data measurement system is needed. Some of the processes to enhance efficiency include:

- Check and optimize the machine or equipment for energy efficiency.

- Integrate torque sensors with automation systems.

- Use torque data for predictive maintenance like the KEYENCE DAQ NR-500 Series.

- Automate data collection and analysis.

- Calibrate equipment regularly to avoid interference with the reading.

Conclusion

Understanding how to measure torque, why the concept of torque is important, and having a proper guide can help you solve problems involving rotational motion and forces. But more importantly, having the right tool will help you properly secure your system and enhance its functions.

Ready to take your torque measurements to the next level? Check out the KEYENCE line of data loggers and data acquisition systems today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us