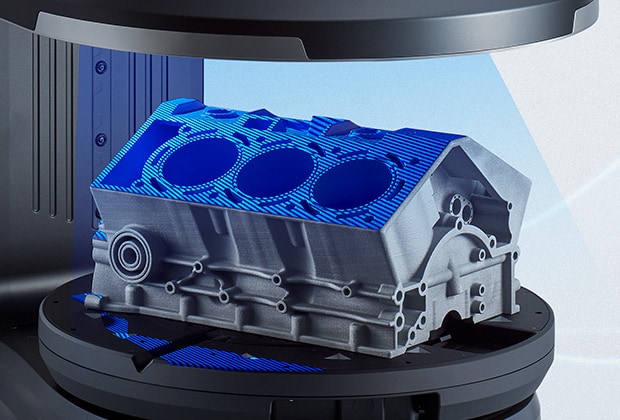

What is a Structured Light Scanner?

Structured light scanners are measurement devices that utilize a structured pattern of light projected onto an object's surface to capture its precise 3D shape. The basic principle involves projecting a known pattern, often a grid or a series of stripes, onto the object being scanned. This pattern deforms as it interacts with the contours of the object. A camera or sensor then captures images of the deformed pattern from different angles.

How does a Structured Light Scanner work?

The deformation of the projected pattern contains valuable information about the object's shape and depth. By analyzing the distortions in the pattern, sophisticated algorithms reconstruct a highly accurate 3D model of the object. This process is known as triangulation, where the scanner calculates the position of each point on the object's surface by comparing the angles and positions of the projected pattern in the images captured by the camera.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

What Are Structured Light Scanners Used For?

Structured light scanners have application across a wide array of industries and fields, owing to their ability to capture detailed 3D data with remarkable accuracy and efficiency. Some common applications include:

- 1.Quality Control and Inspection:

- In manufacturing, structured light scanners play a crucial role in quality control processes. They can quickly and precisely measure the dimensions and tolerances of manufactured parts, ensuring they meet the required specifications.

- 2.Reverse Engineering:

- Engineers and designers use structured light scanners to create digital models of existing objects or components. These models can then be modified, analyzed, or replicated with precision, facilitating the reverse engineering process.

- 3.Medical Imaging:

- In the field of healthcare, structured light scanners aid in the creation of detailed 3D models of anatomical structures, such as bones or organs. These models are invaluable for surgical planning, prosthetics design, and patient education.

- 4.Virtual Reality and Animation:

- Structured light scanners contribute to the creation of lifelike 3D models for use in virtual reality simulations, video games, and animated films. By capturing real-world objects and environments, scanners help blur the lines between the physical and digital realms.

- 5.Artifact Digitalization and Archiving:

- Recording and understanding objects from our ancient past can be difficult or impossible with tactile technology. 3D structured light scanners provide the ability to create renderings and measurements of these objects without the potential for damage.

We’re here to provide you with more details.

Reach out today!

Benefits of Structured Light Scanners

Structured light scanning technology can offer many benefits to industries and businesses seeking precision, efficiency, and innovation:

- 1.High Precision

- Structured light scanners can capture detailed 3D data with sub-millimeter accuracy. This level of precision is essential for applications where minute deviations can have significant consequences.

- 2.Speed and Efficiency

- Compared to traditional measurement techniques, structured light scanners offer rapid data acquisition, enabling faster workflows and reduced time-to-market for products and designs.

- 3.Non-contact Measurement

- Unlike traditional methods such as coordinate measuring machines (CMMs) or calipers, which require physical contact with the object being measured, structured light scanners can capture data without touching the surface. This not only preserves delicate or sensitive objects but also minimizes the risk of damage or distortion.

- 4.Versatility

- Structured light scanners are highly versatile tools that can be adapted to various applications and environments. Whether scanning small mechanical parts, large architectural structures, or human bodies, these scanners offer flexibility without compromising on accuracy or detail.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

From revolutionizing manufacturing processes through precise quality control and reverse engineering to enhancing medical imaging for surgical planning and prosthetics design, structured light 3D scanners have become indispensable tools in modern workflows. Their non-contact nature preserves the integrity of delicate objects while their speed and accuracy expedite workflows, unlocking a world of possibilities across a multitude of industries and applications.

Get detailed information on our products by downloading our catalog.

View Catalog

Related Downloads

Related Products

Scroll