Contact-type Surface Roughness

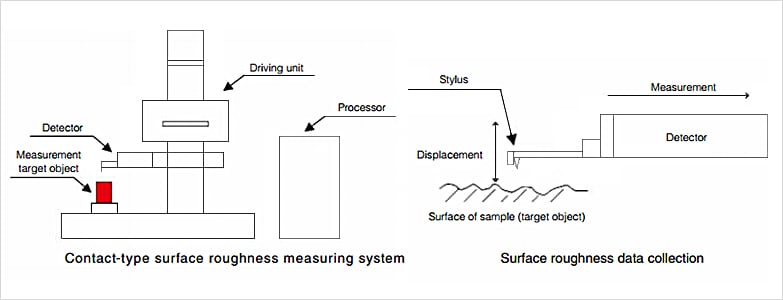

With contact-type surface roughness instruments, a stylus tip makes direct contact with the surface of a sample. The detector tip is equipped with a stylus tip, which traces the surface of the sample and electrically detects the vertial motion of the stylus.

The electrical signals go through an amplification and digital conversion process to be recorded.

To precisely measure delicate shapes and roughness with a contact-type surface roughness tester, the radius of the stylus tip must be as small as possible with low contact pressure.

Styluses are made of sapphire or diamond, and their tip radius is usually about 10 μm 0.39 mil or smaller. A conical shape with a ballpoint tip is considered ideal for a stylus.

Tip radius: r tip = 2 μm 0.08 mil, 5 μm 0.20 mil, 10 μm 0.39 mil

* Cone taper angle: 60º, 90º

* Unless otherwise specified, cones measuring instruments have a 60º taper.