Optimization of Dimensional Measurement of Wooden Products

Wood has many advantages as a material for buildings, furniture, and even casting patterns and molds. Its advantages include its beautiful appearances, high processability, and abundant availability.

However, wood also has disadvantages. Wood has low fire resistance, varying strength according to the fiber direction, and it can shrink and deform due to warpage. However, its greatest disadvantage is variations in quality.

To maintain stable quality while making the most of wood’s advantages and minimizing its disadvantages, it is necessary to inspect it using appropriate dimensional measurement.

This section explains basic knowledge of wood and wooden products, such as deformation mechanisms, the necessity of dimensional measurement, and precautions for measurement. It also introduces the differences in measurement efficiency that arise from differences in measuring instruments and various examples for optimizing these measurements.

- What Is a Wooden Product?

- Causes of Warpage and Bending of Wooden Products

- What Is Precut Lumber?

- Necessity of Dimensional Measurement of Wooden Products

- Dimensional Measurement of Wooden Products

- Problems of Dimensional Measurement of Wooden Products and Their Solutions

- Optimization of Dimensional Measurement of Wooden Products

What Is a Wooden Product?

Wood from trees is used as a raw material or processed into lumber. The terms wood and lumber are often confused, but lumber is wood that has been cut into specified lengths and sizes to be used for constructing buildings or manufacturing products.

In addition to its sensory advantages, such as natural and pleasing textures, wooden products have characteristics that cannot be found in metal, plastic, or other materials, such as the ability to maintain a constant temperature and humidity, processability with high design flexibility, and high thermal insulation properties. Among these characteristics, humidity control, or maintaining a constant humidity, is a great advantage of wood because it absorbs moisture when humidity is too high and discharges moisture when the air becomes too dry.

Wood is also an eco-friendly resource because it can be recycled and resource cycles can be established by planting trees after cutting them down. Products made of wood which make use of the above advantages include not only widely known items such as furniture and pillars and beams for houses, but also wooden casting patterns and molds.

Causes of Warpage and Bending of Wooden Products

Wood has many advantages, but at the same time, it deforms easily, including warpage and bending, and has some other disadvantages. Wood warps and bends for various reasons, and one of the major factors is changes in the water content of wood.

Wood is always breathing. The water content of wood varies as wood repeats a cycle of water discharge and absorption like breathing. Typical wood expands when its water content is high and shrinks when its water content is low. Change in water content differs between heartwood from the center of a tree and sapwood from the outer layers, resulting in differences in expansion and contraction. Expansion and contraction also differ according to the grain direction. These differences in expansion and contraction cause warpage and bending.

Wood is most likely to warp or bend when its water content is 20% to 30%. To prevent these defects, wood is usually fully dried, its surface is coated, or other measures are taken. Additionally, wood that is not easy to warp or bend has been developed, such as processed wood, including plywood, and engineered wood* which includes laminated wood and cross-laminated timber (CLT).

- Engineered wood:

- Engineered wood is a type of wood developed to overcome the drawbacks of wood. Recently, technologies that compensate for the drawbacks, such as warpage, bending, and particularly large strength variations, by performing secondary processing on wood have advanced. Typical examples of engineered wood include laminated wood and CLT.

What Is Precut Lumber?

Precut lumber is wooden products that have been machined in factories. Processing of joints for horizontal and angled connections and metal fittings of pillars and beams used for wooden houses is typically performed manually by craftspeople such as carpenters. Mechanizing this work can improve parts processing accuracy, stabilize quality, reduce work at construction sites, shorten construction periods, and brings other benefits. Precut lumber is also used as a way to improve the added value of wooden parts, streamline distribution and sales, increase demand for wooden houses, and augment other benefits of wooden parts.

With the recent introduction of fully automated CAD/CAM using computers, it has become possible to machine pillars, beams, louver slats, panels, and other materials for wooden houses with high accuracy. Processing data of a wooden house created with CAD, such as 2D and 3D diagrams, is transferred to CAM which then automatically cuts lumber. Total management of housing construction processes, including quality control and standardization of wooden products, structural design, and construction, is becoming possible.

- Wooden framework construction method:

- This method combines pillars and beams to build a house. This is the method most commonly used in Japan.

Necessity of Dimensional Measurement of Wooden Products

Moisture-retaining properties and highly flexible processability of wood can cause dimensional errors. For this reason, wooden products need to be strictly inspected by measuring their dimensions.

Precut lumber

Precut lumber with highly accurate dimensions and shapes is manufactured by processing engineered wood, such as laminated wood that does not easily deform, with computer-controlled machine tools. However, machining failures can occur due to incorrect CAD data input or machine tool malfunctions. For example, a house cannot be built as designed using wooden products with incorrect dimensions. If the shape and dimensions of joints for angled connections have low accuracy, it needs to be corrected on-site. These problems will be the source of serious complaints.

Building materials and furniture

Wood may deform due to its nature, humidity, dryness, and other factors even after it is processed in many different ways. Deformation can occur anywhere wood is used, including house building and furniture, causing problems such as joint fit failures in horizontal and angled connections and metal fittings during construction or assembly. When this happens, on-site processing is required.

Wooden casting patterns and molds

Wooden casting patterns and molds support full-mold casting. The full-mold casting process is suitable for small numbers of products, including single products, and its high processing flexibility allows for casting of complex shapes easily at low cost. If wooden casting patterns and molds are deformed due to inappropriate storage or worn due to insufficient maintenance, all castings made with them will be defective. In casting, wooden patterns and molds are the most important parts that determine the dimensional accuracy of castings. Their dimensions must be measured before use.

Dimensional Measurement of Wooden Products

Unlike machined metal or resin products, high dimensional accuracy is not required for wooden products. However, wood deforms easily, so it requires inspection in some processes, such as drying, machining, and product manufacturing, by sequential measurement.

Dimensional measurement points of wooden products

For wooden products, warpage, distortion, and wear need to be checked by dimensional measurement. This section explains dimensional measurement of precut lumber, furniture, and wooden casting patterns and molds.

Warpage and distortion of precut lumber and dimensions of joints for angled connection

Precut lumber, which has been cut into required shapes in factories, is made of wood that does not easily deform even when exposed to humidity, but it can still warp or distort. Long pieces of precut lumber, in particular, are more likely to deform. This means that the dimensions of lumber must be measured before and after precutting. The shape and dimensions of joints for angled connection and the bolt hole dimensions and pitch of metal fittings also need to be checked because these elements greatly affect construction accuracy.

Warpage, distortion, and dowel positions of wooden furniture

Warpage and distortion of wooden furniture parts can cause strain during assembly. Warpage and distortion also affect durability, door opening and closing, and sealing performance, so the outer dimensions of assembled furniture are important measurement points in addition to dimensions of its parts. Dowel positions and dowel hole pitches are also essential measurement points.

Shape of wooden casting patterns and molds

Many wooden casting patterns and molds are automatically machined using CAD data. However, changes in dimensions after manufacturing, such as deformation due to humidity and wear caused during use, directly affect the dimensional accuracy of castings. Their dimensions are important measurement points that need to be compared with CAD data.

Problems of Dimensional Measurement of Wooden Products and Their Solutions

In the manufacturing of building parts and furniture parts, it is important to not only measure the dimensions of the parts but items such as the perpendicularity and parallelism after construction or assembly. Three-dimensional measurement is also required because many wooden casting patterns and molds have complex shapes.

These measurements are performed using calipers, tape measures, and similar tools. However, measurements of long parts require multiple workers, so their measurements and adjustments take a lot of time and effort, affecting the delivery date. This has been a problem.Also, it is not possible to directly measure 3D shapes with hand tools such as calipers and tape measures, so arm CMMs are used for these measurements. However, the operator performing the measurement needs to have detailed knowledge of measurement and to use arm CMMs. Additionally, arm CMMs need to have analysis functions such as output functions that enables comparison with CAD data and CAD data creation from measurement data.

To solve these problems, the latest CMMs are used in an increasing number of cases.

KEYENCE’s Wide Area Coordinate Measuring Machine WM Series enables high-accuracy measurement of pillars and beams multiple meters in length with the wireless probe. Even recessed areas of products can be reached with no movement restrictions within the measurement range, which allows for single-person measurement with the simple operation of touching targets with the probe. Unlike measurements using measuring instruments such as calipers and tape measures, results do not vary, enabling quantitative measurement. The WM Series is also equipped with functions that can compare measurement data with CAD data and create CAD data from measurement data.

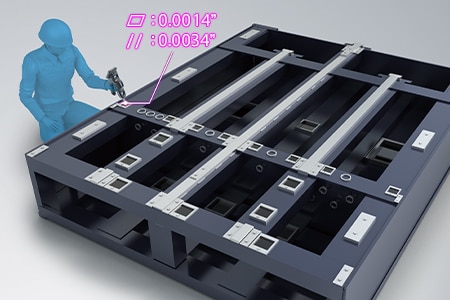

Warpage and distortion measurement of precut lumber and dimensional measurement of angled joints

Large-scale precut lumber dimensions and metal fitting positions and pitches are measured by multiple workers with tape measures. Warpage and distortion are measured with laser levels while the dimensions and flatness of joints for angled connection are measured with tape measures and angle gauges.

However, the large number of measurement points makes this work require a lot of time and measured values vary according to the angle and strength used when the operators apply measuring instruments to the target. It is also difficult to accurately grasp the inspection conditions and inspection points, which makes it difficult to manage measurement data and issue inspection reports.

The WM Series enables the operator to perform measurements by simply touching the probe to the positions to measure. Simply by touching the target with the probe, the operator can measure not just the outer dimensions of precut lumber but the positions and pitches of metal fittings and the dimensions and flatness of joints for angled connection as well. Also, it is also possible to directly measure 3D shapes such as warpage and distortion.

Furthermore, inspection reports can be automatically created with photos that allow you to understand measurement points at a glance. These inspection reports can not only gain you the trust of your business partners but also allow you to save measurement results as digital data, leading to higher efficiency of in-house data management.

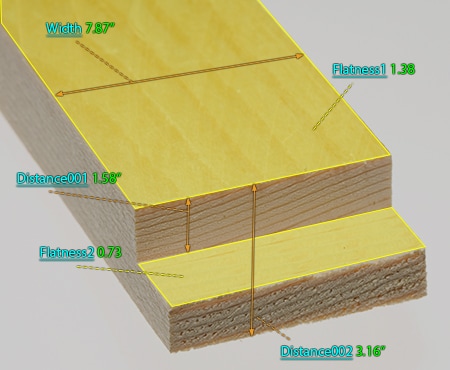

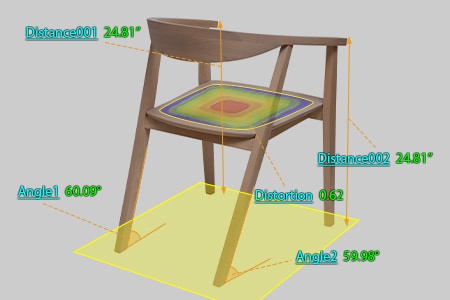

Dimensional, warpage, and distortion measurement of wooden furniture

The dimensions, angles, warpage, distortion, and dowel positions of wooden furniture parts affect the assembly accuracy. Therefore, dimensional inspections are important not only during manufacturing but after assembly as well.

The dimensions, angles, and dowel positions of wooden furniture parts are measured with tape measures. However, multiple workers are required for such measurements, making them inefficient. What’s more, it was difficult to convert warpage and distortion to values.

The WM Series enables single-person measurement of the dimensions, angles, warpage, and distortion of wooden furniture parts by simply touching the probe to the positions to measure. The measured warpage and distortion as well as dimensions can be converted to values as flatness, and the distance between virtual lines can also be visualized. Furthermore, it is also possible to easily measure virtual distances and 3D dimensions such as the dowel positions and pitches and the distance from the center of a door to an edge face.

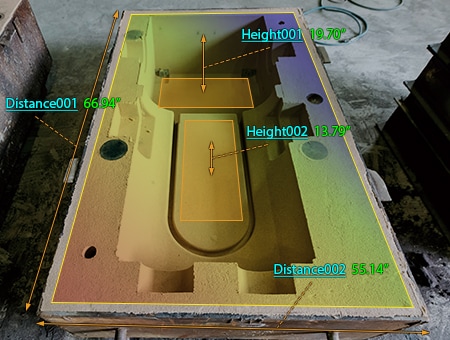

CAD comparison of the shape of wooden casting patterns and molds

Wooden casting patterns and molds are created larger than the actual size by the amount of contraction that occurs when melted metal solidifies. This amount is considered to be approximately 9/1000 to 12/1000 in many cases, and the dimensions of a wooden casting pattern or mold created by adding this amount greatly affects the accuracy of castings. It is essential to measure the dimensions of the parts of wooden casting patterns and molds. However, measured values vary according to the position at which a hand tool, such as a caliper or tape measure, is applied to the target, which makes it impossible to prevent variations in measured values among operators. It is also difficult to measure virtual distances and perform 3D measurements. When an arm CMM is used, the measurement range is limited due to its small movement range. Furthermore, only highly skilled operators can perform measurement with this measuring instrument.

With the WM Series, it is possible for a single person to accurately measure a wide area with the simple operation of touching measurement points with the probe. The WM Series is equipped with a function that enables measurement at the same point according to a memorized measurement procedure, allowing anyone to obtain the same measurement data.

Simply by touching with the probe, the operator can measure not only basic outer dimensions but also complex shapes formed with free curves. Even 3D position coordinates can be measured. Deviations from designed tolerances can also be judged instantaneously. The measured elements can be checked with CAD data and exported as a STEP/IGES file. These features enable the creation of accurate wooden casting patterns and molds and also 3D CAD data based on the measurement results of an actual product, even if no drawing is available.

Optimization of Dimensional Measurement of Wooden Products

The WM Series enables single-person measurement of large-scale wooden products with the simple operation of touching the wireless probe to the measurement point. In addition to the features introduced above, the WM Series has the following advantages.

- High-accuracy measurement over a large area

- A wide measurement range up to 25 m (82.0'′) can be measured with high accuracy. The WM Series is equipped with the navigation measurement mode, which enables measurement at the same point according to a memorized measurement procedure, allowing anyone to obtain the same measurement data.

- The portable body can be placed on-site

- The main unit can be carried around on the cart. The WM Series can be brought into worksites and immediately measure the status of work.

- Easy-to-understand interface

- CMM interfaces are often a mess of complex and unfamiliar commands. The WM Series provides intuitive operation using images and icons, so anyone can easily understand how to operate the system.

- Statistical Analysis function for summarizing data

- Measurement results from guided measurement will be automatically saved to the hard disk drive. Saved data can then be extracted for use with various statistic analyses such as checks of the statistical values, trend graphs, and histograms.

The WM Series strongly supports post-measurement work, such as comparison with 3D CAD data and inspection report issuance, as well as dimensional measurement of wooden products. It dramatically improves the efficiency of a wide variety of work for wooden products such as manufacturing, dimensional check after assembly, and quality control.