Industrial Inkjet Printer Types

Mechanisms of print, a brief technical description of the most commonly used methods to generate ink droplets for various industrial inkjet printers. Understanding what each mechanism is used for and what industries and applications they are best suited for.

On-Demand Type

With this method, only the amount of ink particles necessary for printing is discharged.

The ink nozzles are arranged vertically within the printer. Ink particles are instantaneously discharged from the nozzle and are sprayed on the target. Piezo, thermal, and valve are the methods used to apply pressure to the ink particles and discharge them.

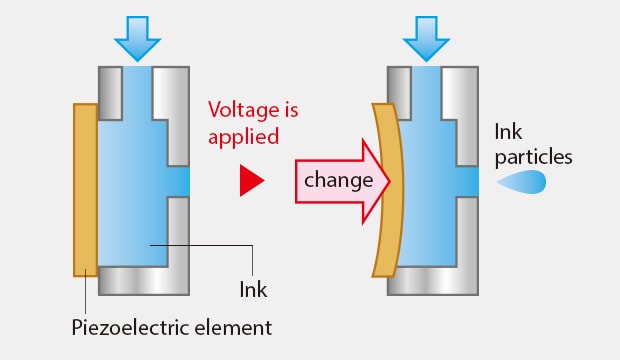

Piezoelectric Type (Office/Industrial)

In this method, a piezoelectric (piezo) element that changes its volume when voltage is applied, is used to discharge ink particles. This element is attached to the component that is filled with ink. Then, the volume deformations are used to apply pressure to the ink, which discharges ink particles from the nozzle.

Advantages

- The amount of ink discharged can be controlled with high accuracy by controlling the voltage.

- Because it does not apply heat to the ink, this method is highly durable and resistant to the influence of the operating environment.

Disadvantages

- Because a piezo element is required for each nozzle, the structure can become complicated.

- It is easy for nozzles to become clogged if air bubbles form in the ink.

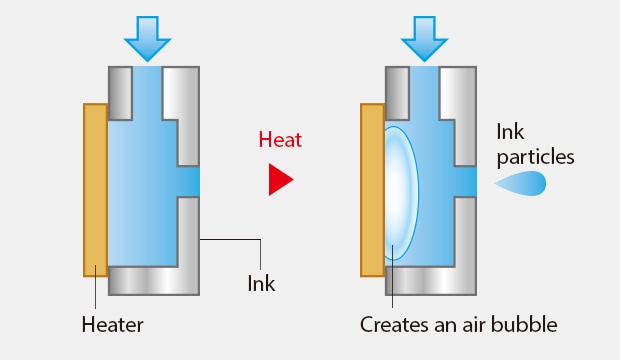

Thermal (Valve) Type (Office/Industrial)

In this method, a heating element is used to apply heat to the ink, which causes bubbles to form and discharge ink particles. The heating element is attached to the component that is filled with ink. Applying heat to the ink causes a bubble to form, which discharges ink particles from the nozzle.

Advantages

- The structure is comparatively simple, which makes it easy to miniaturize these printers.

- It is easy to improve the printing resolution.

Disadvantages

- It is easy for the ink to deteriorate due to the heat applied.

- Print heads have short service lives.

- Because moisture evaporates from the nozzles, it is easy for nozzles to be clogged due to drying out.

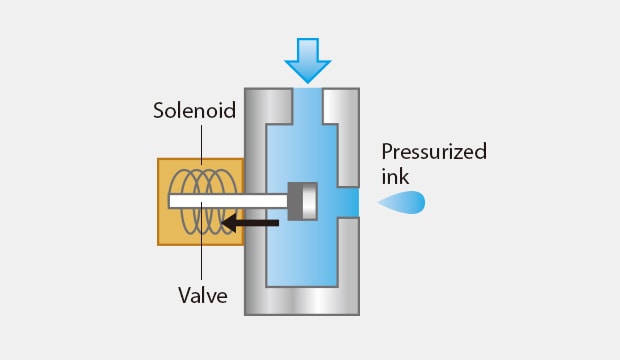

Valve Type (Industrial)

In this method, a solenoid is used to open and close the nozzle cover, which discharges ink particles.

By opening and closing the valve, the pressurized ink is discharged from the nozzle.

Advantages

- Because pressurized ink is discharged, it is easy to increase the distance from the nozzle to the target.

Disadvantages

- Because the ink particles are large, it is easy for the print quality to degrade.

We’re here to provide you with more details.

Reach out today!

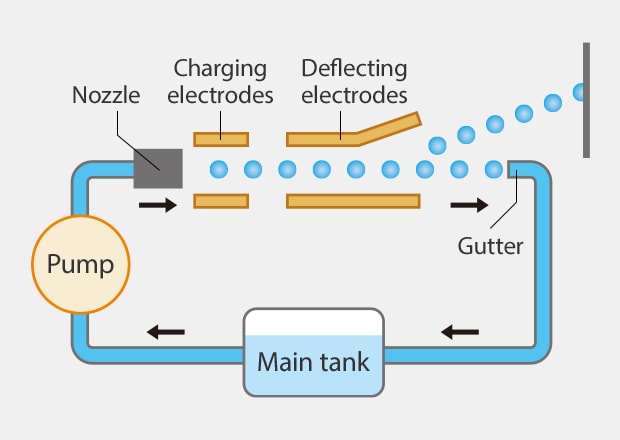

Continuous Type

In this method, ink particles are continuously discharged from the nozzle. The ink particles are charged with electrostatic, and deflecting electrodes are used to deflect the ink particles so that they are sprayed on the printing surface.

Ink particles that are not deflected are collected, returned to the ink tank, and reused. Even when printing is not being performed, ink is continuously discharged at all times, which is why they are called continuous-type printers. This is the most commonly used method among industrial inkjet printers.

Advantages

- Because the ink is discharged at high pressure, highly viscous ink can be used.

- Because ink is discharged continuously, quick-drying ink can be used.

Disadvantages

- Due to the large-scale structure, it is difficult to miniaturize these printers. These printers are not suited for office use.

Discover more about this product.

Click here to book your demo.

Applications of Different Types of Inkjet Printers

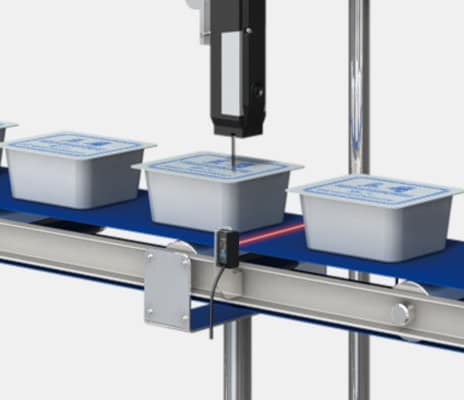

Inkjet printers are generally divided into two main categories: continuous inkjet (CIJ) printers and on-demand inkjet printers. CIJs are ideal for high-speed, non-contact printing on various substrates, such as metals, plastics, and glass. They use a constant stream of ink droplets to create characters and images on the product's surface.

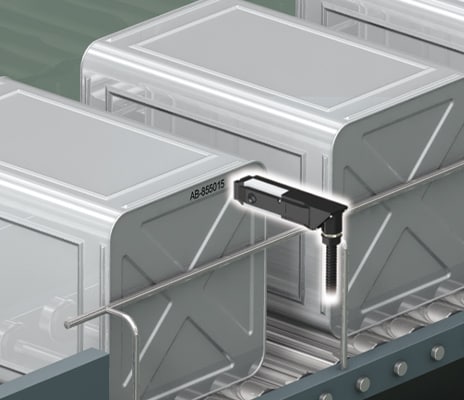

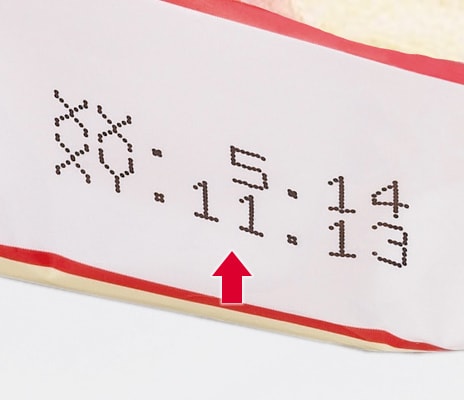

These printers are often used for applications such as date coding, lot coding, expiration dates, and other essential information that needs to be printed at high speeds with precision and accuracy. They can also be mounted on a rotary machine that will replace conventional stamp marking with inkjet printing.

Installation Examples

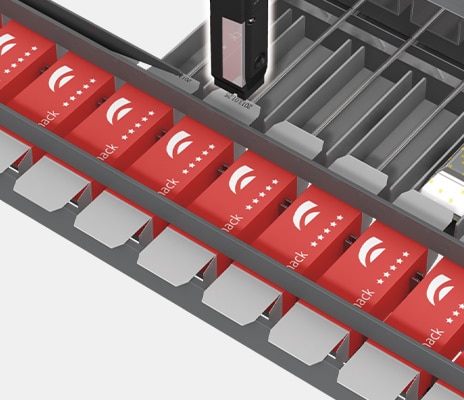

Vertical form-filled packaging machine

Cartoner

Grip conveyor

Line conveyor

Designated conveyor

Sealer

Heat sealer

Hopper labeler

Defect inspection printing

Extrusion molding machine

Conveyor (diagonal application)

Conveyor (horizontal application)

KEYENCE's MK-G Series is a continuous inkjet printer designed specifically for date coding and lot coding applications. Print quality is essential in these applications, as the printed information needs to be clear and readable at high speeds.

A common issue with CIJ printers is inconsistent droplet placement, resulting in blurry or distorted characters. The MK-G Series offers advanced features such as auto-shower cleaning, effectively cleaning the entire ink path, and other necessary components to maintain print quality. The built-in blower also automatically dries the print head after cleaning, reducing odors and ensuring efficient operation, while a conditioning tank collects the solvent after cleaning for consistent droplet placement and reduces the risk of clogging or smudging.

CIJ printers often operate in dirty or wet conditions. This creates problems for the machines as the ink can get contaminated, the machine itself can get damaged, and the print quality can suffer. The MK-G Series is especially adept at operating in these environments, as it has an IP55 structure all around, making it highly resistant to water and dust. Additionally, the head and console of the printer are MIL Standard drop resistant, which is an industry first.

The MK-G Series is rated IP55, making it both waterproof and dustproof.

No Need to Worry About Water Exposure

IP55-rated head & controller

In addition to the controller and console, which were rated IP55 in previous models, the new MK-G Series incorporates an all-around IP55 structure, including the head, the MK Dock, and the Operation Assist Camera. The head is rated IP55 when not ejecting ink.

Both the head and the console comply with MIL Standard drop evaluation requirements.

Solid Jacket Provides Superior Fall Protection

INDUSTRY FIRST:

MIL standard-compliant drop-resistant structue

The head and console—two components often picked up and moved—come equipped with a robust, dedicated jacket. The structure of these devices, as well as the Operation Assist Camera, can withstand accidental drops.

Get detailed information on our products by downloading our catalog.

View Catalog

Choosing the Right Type of Inkjet Printing Technology

Choosing the right type of inkjet printing technology can significantly impact productivity, print quality, and overall cost-effectiveness. Several factors should be considered when determining which industrial inkjet printer type is best for your application.

One of the most critical considerations is the type of product material and environment in which the printer will be used. CIJ printers are suitable for a wide range of materials, including plastic, glass, metal, and paper. They can also be used in various environments, from clean production facilities to harsh industrial environments.

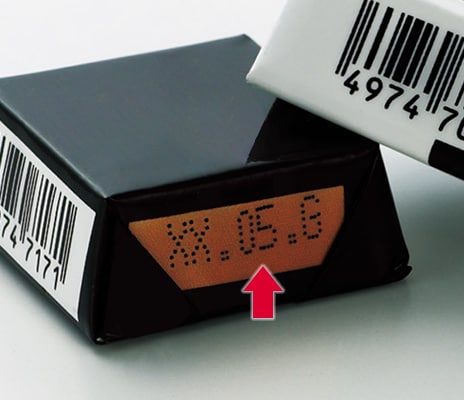

Marking Examples

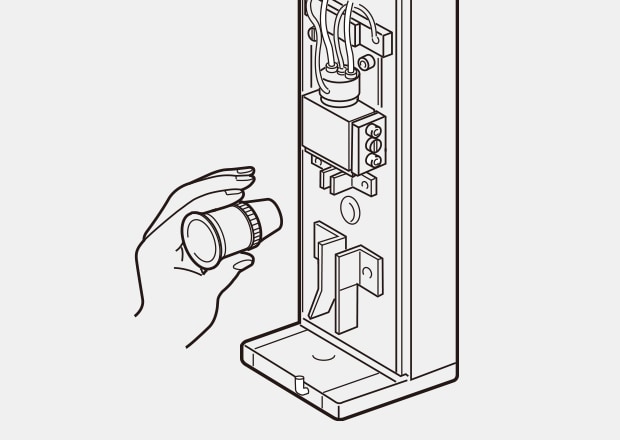

KEYENCE's MK-G Series is more suited to industrial environments than typical CIJ printers as it is highly resistant to water, dust, and impact. This makes it an excellent choice for industries such as food and beverage, pharmaceuticals, and electronics manufacturing. The unique features of the MK-G Series, such as auto-shower cleaning, performance analytics, and one-touch nozzle replacement, make it stand out from its competitors for industrial inkjet printing.

Another essential factor to consider is the type of information that needs to be printed. CIJ printers are capable of printing alphanumeric text, logos, barcodes, and other variable data such as expiration dates, lot codes, and serial numbers. This versatility makes them suitable for a wide range of applications, from product packaging to hopper labelers.

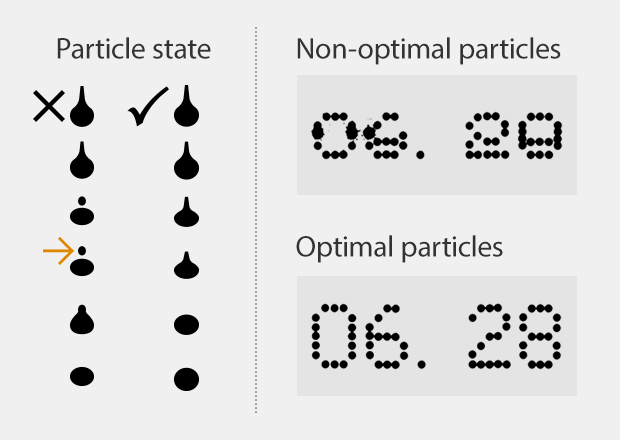

The MK-G Series provides superior print quality over other CIJ printers using advanced technology, such as automatic ink particle optimization. This ensures consistent and clear printing by sensing the ink particles 10 times per second. Additionally, the series offers print inspection equipment connectivity for real-time monitoring of print quality to ensure 100% accuracy and consistency.

Another factor is the required print quality. CIJ printers are known for their high-speed printing capabilities but may not always provide the best resolution for intricate designs or small fonts. In contrast, TTO printers excel at printing high-resolution graphics, making them suitable for applications that require crisp and clear images.

With conventional CIJ printers, an operator uses a magnifying glass to check the shape of the ink particles visually. It is difficult to determine the proper state, so adjustment has to be repeated several times. The MK-G Series automatically senses the ink particles 10 times per second to maintain the optimal state at all times.

Conventional

Adjustment with a magnifying glass

MK-G Series

The printer senses the particle state to maintain the optimal state at all times

Curious about our pricing?

Click here to find out more.

Industrial Inkjet Printer Types FAQs

What Are the Main Types of Inkjet Printers?

There are two main types of inkjet printers: continuous inkjet printers and on-demand inkjet printers. Continuous inkjet printers are ideal for high-speed printing applications and can produce a large number of low-resolution prints quickly. On the other hand, on-demand inkjet printers are better suited for printing high-resolution graphics and text for barcodes and product identification.

Are There Specific Considerations When Choosing Types of Inkjet Printing Technology for Packaging Applications?

Several considerations come into play when choosing the industrial inkjet printer for your packaging application, particularly if we’re discussing industrial, high-volume use. Substrate compatibility is the main consideration when choosing the printer for packaging applications.

Print speed and volume are the second most important factors, and CIJ printers are ideal for high-speed, high-volume packing lines where downtime needs to be reduced.

Lastly, consider the initial investment versus operational costs. This includes the initial purchase price, maintenance costs, ink consumptions, and any other print-specific consumables. Continuous inkjet printers might feature a heftier price tag initially, but they offer lower per-print costs at high volumes, which benefits your bottom line.

What Are the Maintenance Requirements for Different Types of Inkjet Printers?

Different industrial inkjet printer types feature their own maintenance requirements. Fortunately, the KEYENCE MK-G Series performs most of the maintenance on its own, including self-cleaning the ink path and the print head while also circulating the solvent into the conditioning tank. This is particularly helpful when undergoing employee changeover. Inexperienced operators will be able to easily follow the on-screen instructions, minimizing disruption to workflow.

Are There Environmental Considerations When Choosing Between Industrial Inkjet Printer Types?

Yes, there are certain environmental considerations one must take into account when choosing an industrial inkjet printer or coder. Those considerations include the type of environment the printer will operate in, as well as any potential environmental regulations or restrictions that may apply. Ink composition, biodegradability, energy consumption, and waste generation must also be considered.

If you want to upgrade your industrial printing, KEYENCE offers comprehensive industrial printing and print quality assurance solutions, so don’t hesitate to contact us!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Inkjet Printer Tech Guide [BASIC KNOWLEDGE EDITION]](/img/asset/AS_139230_L.jpg)