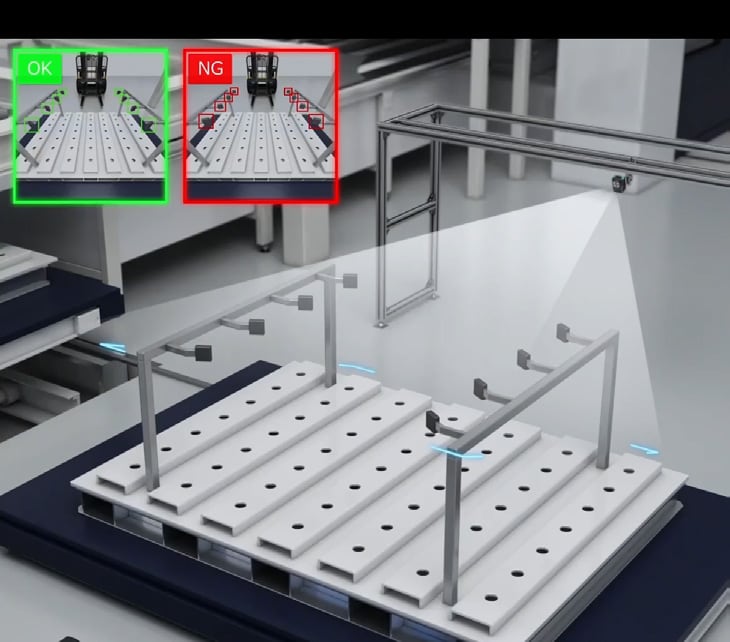

Reverse Set Detection of Hanger Before Installing Panel

-

Industry:

- Automotive

-

Products:

- Machine Vision

This allows users to avoid long-term line stoppages. A pallet set in the reverse direction with a forklift may cause interference with equipment or line stoppages when it moves on to the next process (panel installation). Advance detection with the IV Series can prevent a piece that has been incorrectly set from advancing on to the next process. This was determined with a color sensor in the past, but there was a possibility of erroneous detection due to factors such as dust or dirt, and individual differences. Pallets are made up of outer pallets and inner pallets, and there are cases where only the inner pallet was set in reverse during the previous process. This means that human visual inspection will not be enough to identify pieces set in reverse.