Detections of seal lip peeling and scratches

-

Industry:

- Metals

-

Products:

- Measurement Sensors

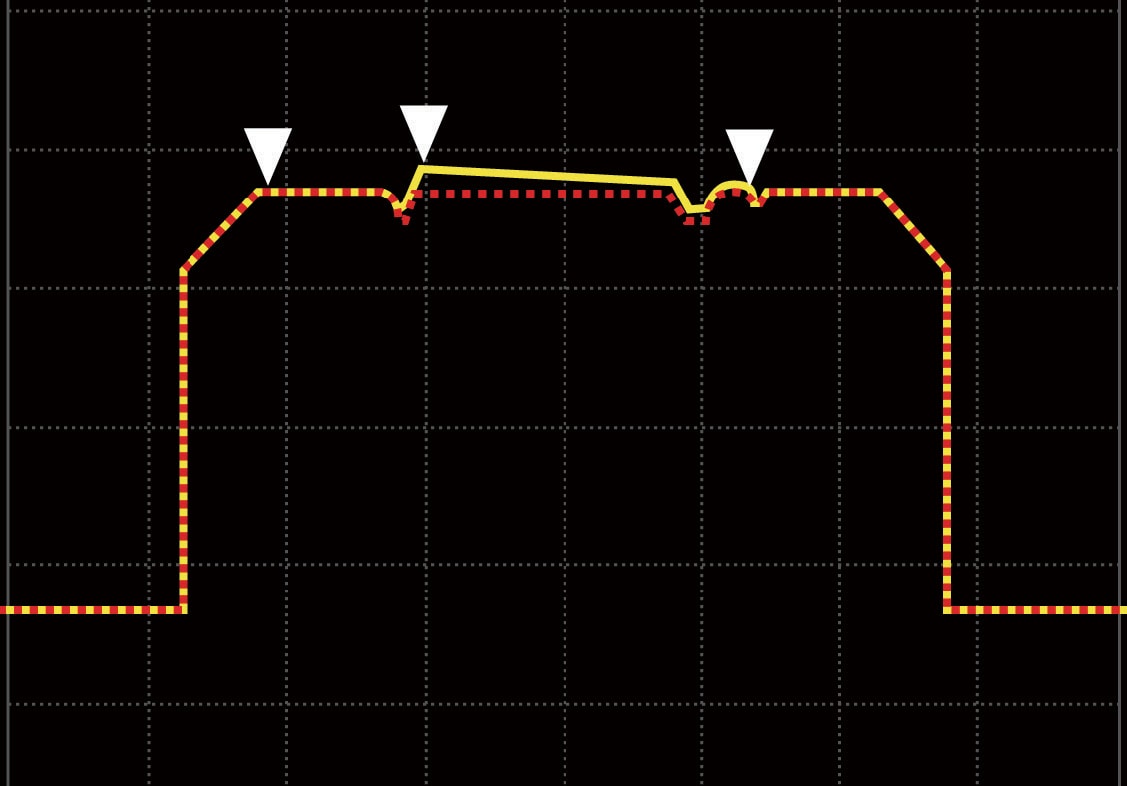

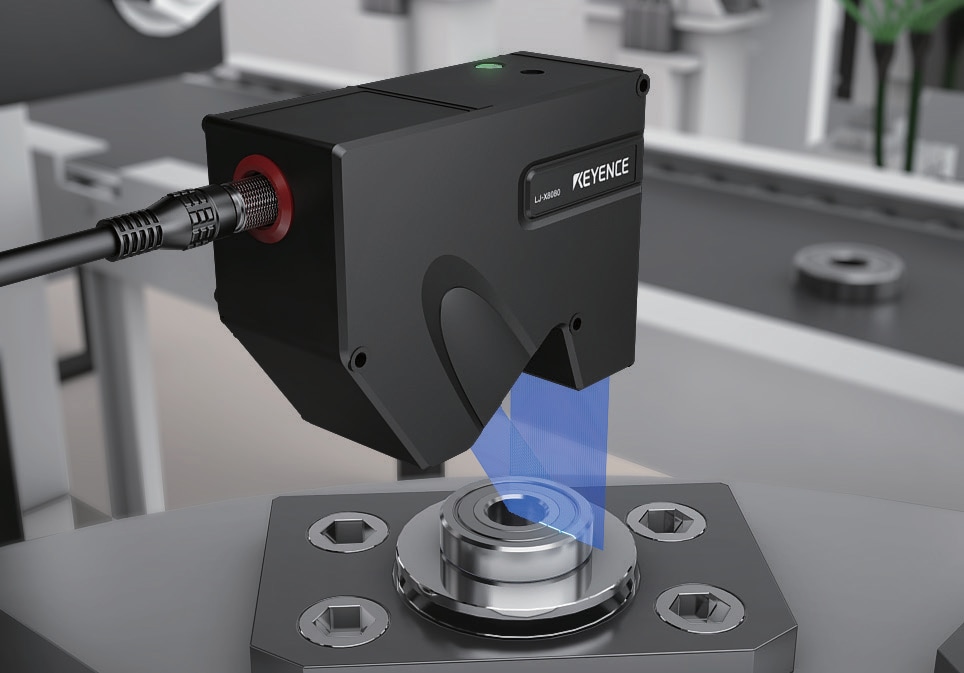

The lip part of seals can peel off easily, so the LJ-X is used to inspect for this problem. Since the location where the peel started is unknown, the bearing must be rotated to inspect its entire circumference. Due to the miniaturization of bearings and the increase in the number of bearings produced, there are demands for both improved inspection time and improved inspection capability. The LJ-X Series can perform ultra-high-resolution measurements with 3200 points/profile, and its lineup also includes an ultra-fast measurement head capable of speeds up to 64000 profiles/second. Also, the rich variety of measurement and inspection tools can be used to simultaneously perform a variety of inspections, such as measurements of the overall height and shape of the seal and the surface runout of the inner and outer races.