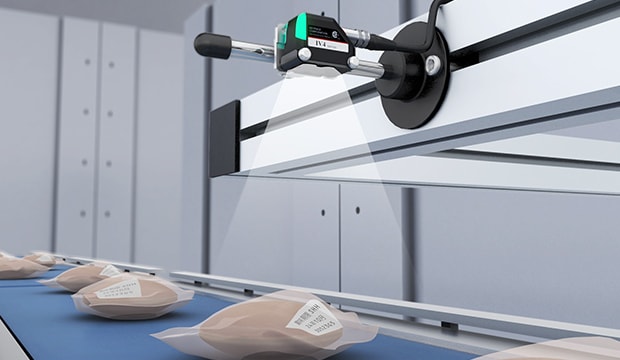

Vision Sensor with Built-in AI

IV4 series

Applications Vision Sensor with Built-in AI IV4 series

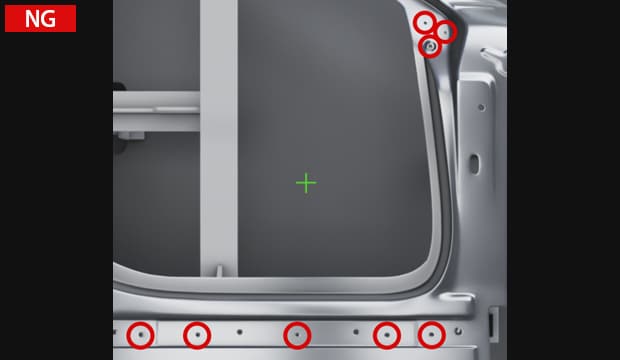

Presence/Absence-Based Identification

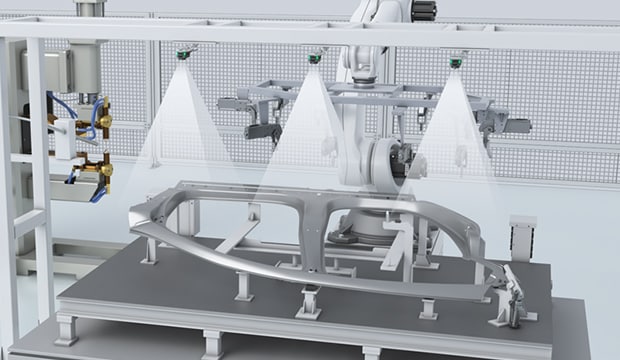

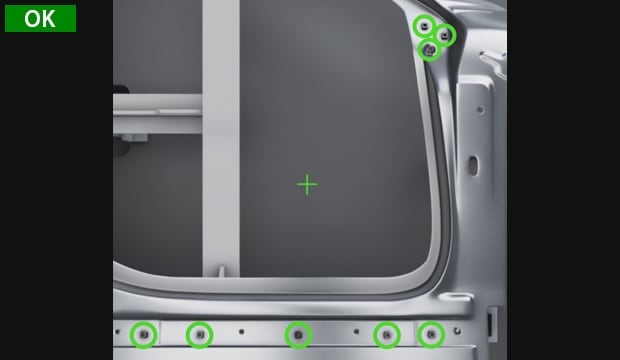

Automotive/Metal industries Nut Presence Detection

Inspection is performed to determine whether a nut is attached to the panel. Presence checking can be performed for multiple locations using just one device.

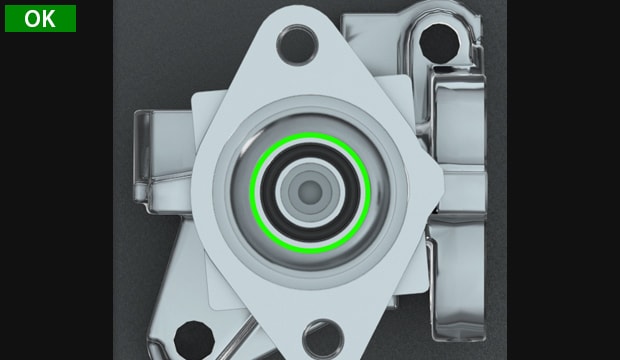

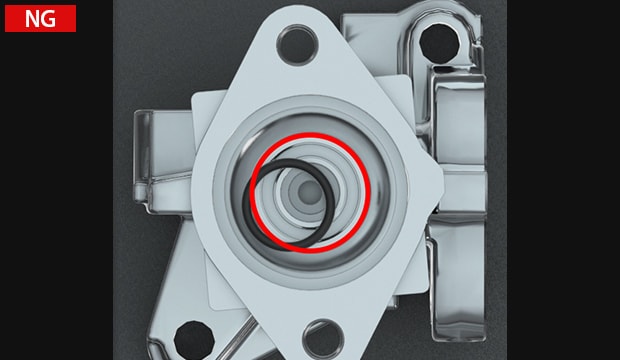

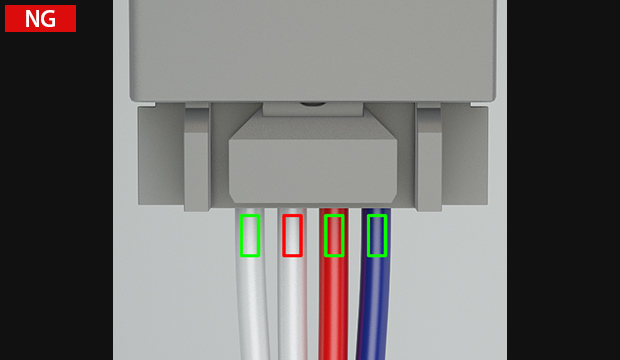

Automotive/Metal industries O-Ring Presence Checking

Presence checking is performed for O-rings. The IV4 Series can check not only for the presence of targets but also whether targets are set correctly.

Packaging/Food/Pharmaceutical industries Label Presence Checking and Misalignment Detection

In addition to checking for the presence of labels, checking for proper label alignment is also possible.

Color-Based Identification

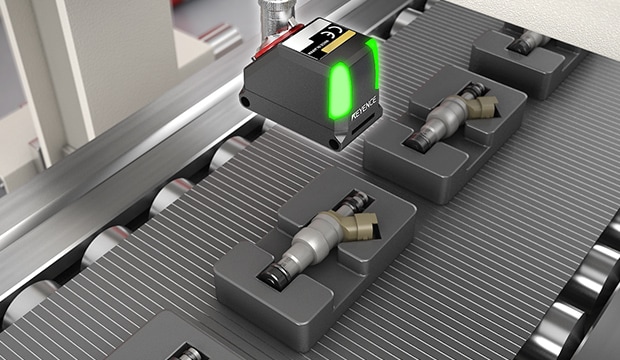

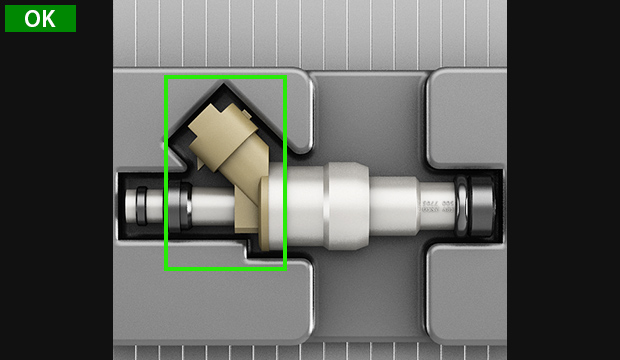

Automotive/Metal industries Injector Type Difference Checking

Injector product differentiation is possible based on color differences of the component parts. Tracking makes detection possible even if the detection position changes.

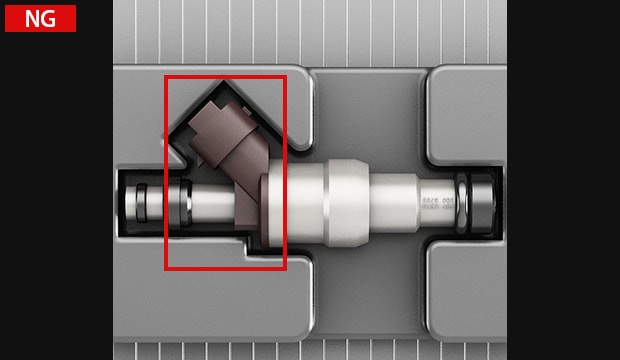

Electrical/Semiconductor industries Capacitor Orientation Detection

When differentiating between directional capacitors, accurate identification of differences that are not easy to spot with visual inspection is possible.

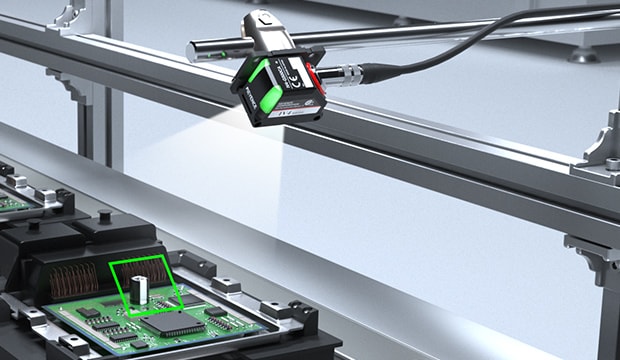

Electrical/Semiconductor industries Connector Cable Color Difference Check

Accurate detection is possible with a single unit even in locations where multiple sensors are required and there is the risk of target displacement.

Shape-Based Identification

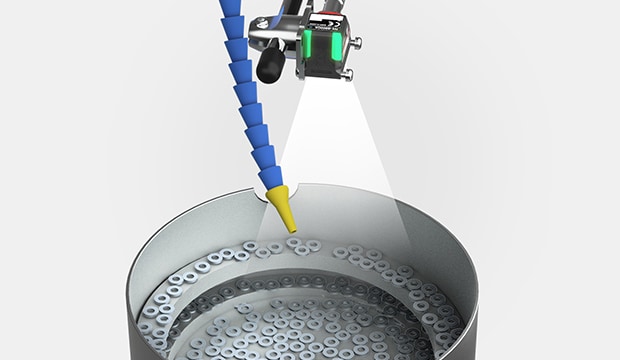

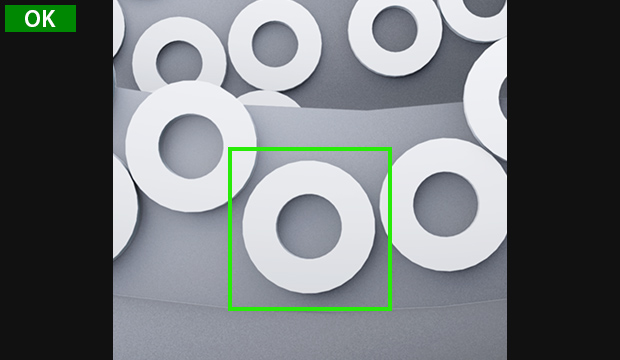

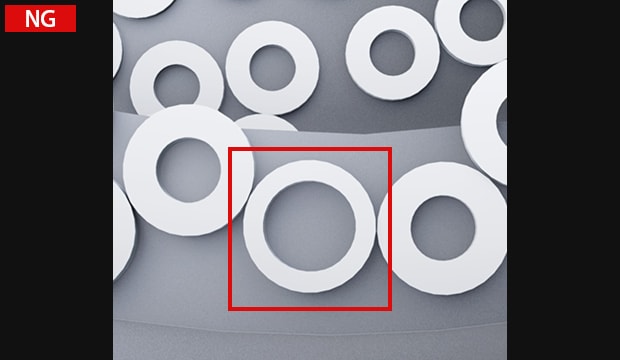

Automotive/Metal industries O-Ring Type Difference Checking

Product type differentiation can be performed directly from the parts feeder with accurate identification of shape differences even in targets of the same size.

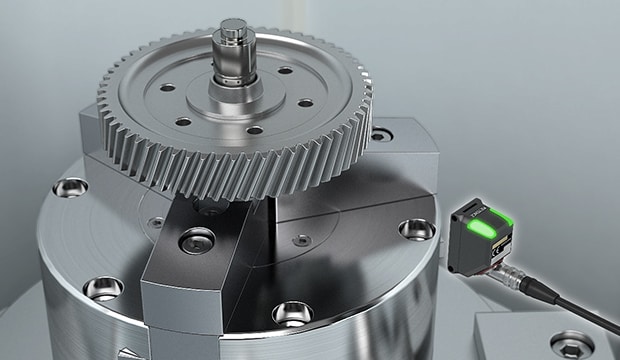

Automotive/Metal industries Gear Type Difference Checking

The IV4 Series can determine whether gears are set correctly by accurately identifying differences that are not easy to see with visual inspection.

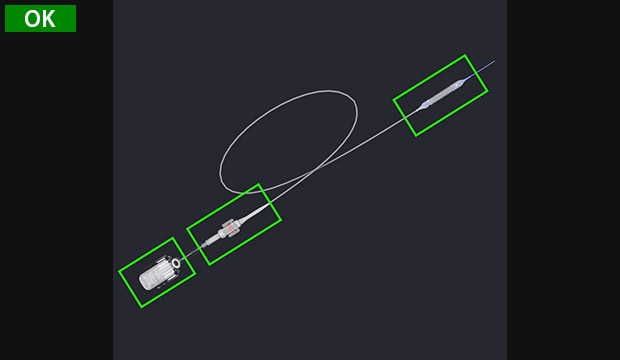

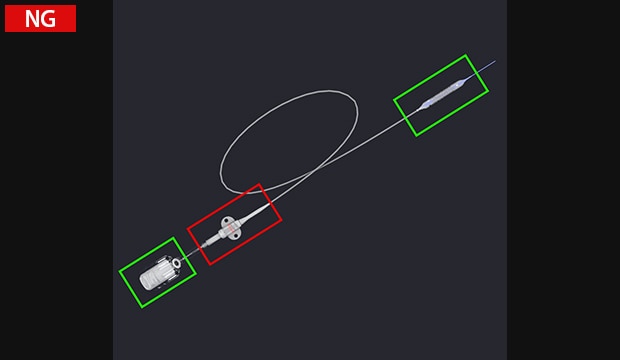

Packaging/Food/Pharmaceutical industries Tube-Based Pharmaceutical Product Assembly Check

Identifying the different shapes of products even if the position or orientation varies makes it possible to ensure medical tubing is installed correctly.

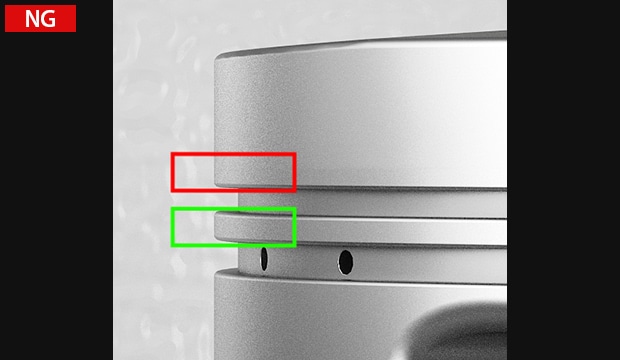

Dimension/Edge-Based Identification

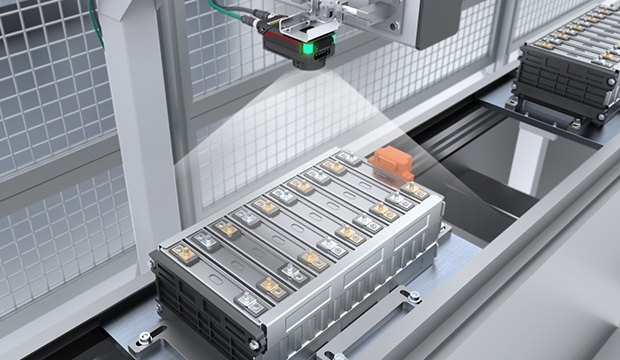

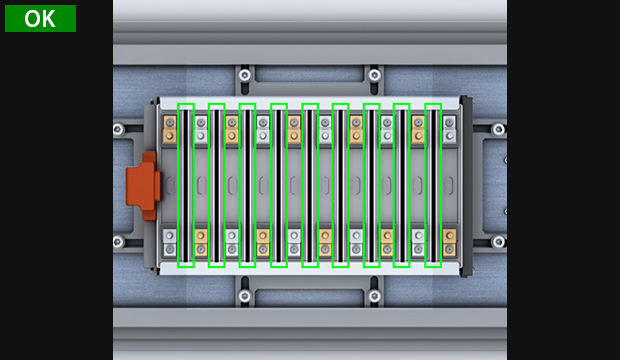

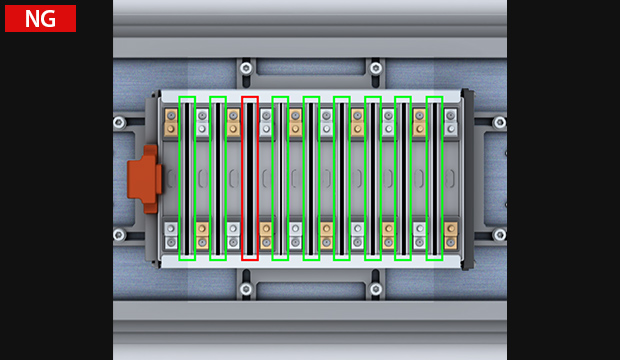

Automotive/Metal industries Assembly Gap Detection

To detect gaps during battery assembly, the width dimension is measured to determine whether the gap is within the acceptable specifications.

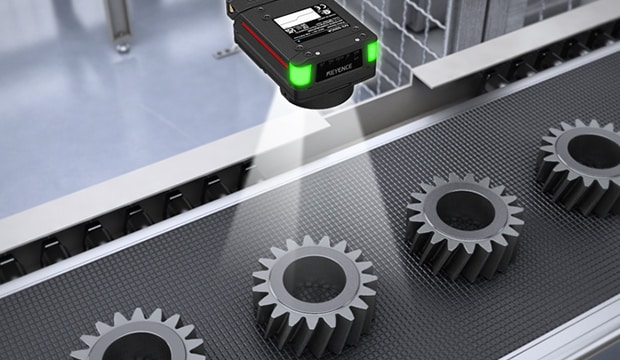

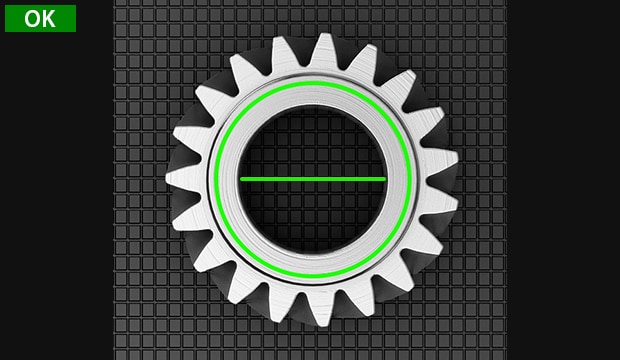

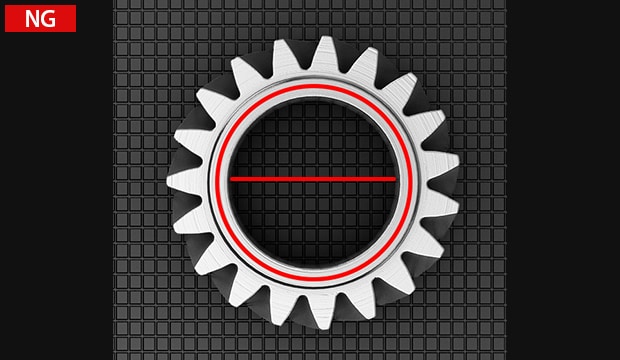

Automotive/Metal industries Gear Size Difference Checking

During gear transferring, the IV4 Series can determine if the gear is oriented correctly. Differentiating between gear sizes is also possible by looking at the inner diameter (dimension).

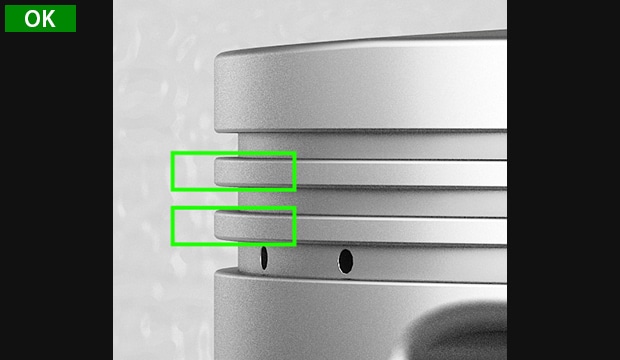

Automotive/Metal industries Piston Type Difference Checking

To check for different piston types, the number of grooves (edges) on the target product are counted.

OCR-Based Identification

Automotive/Metal industries Confirmation of Printing on Rubber Parts

The IV4 Series can check markings on rubber parts, and detection is stable even if the characters are the same color as the background.

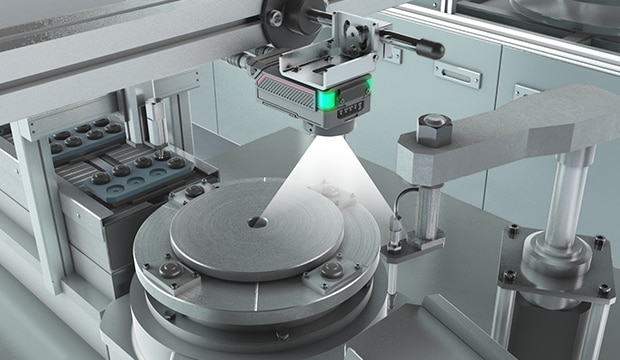

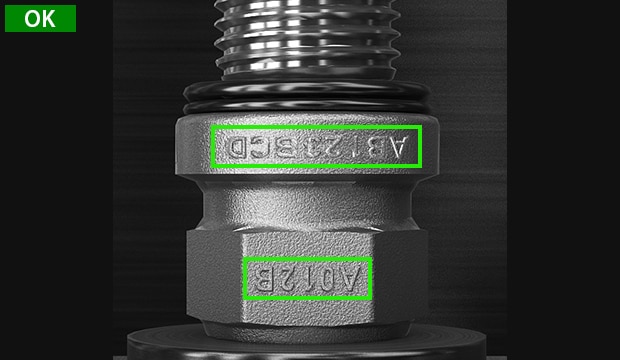

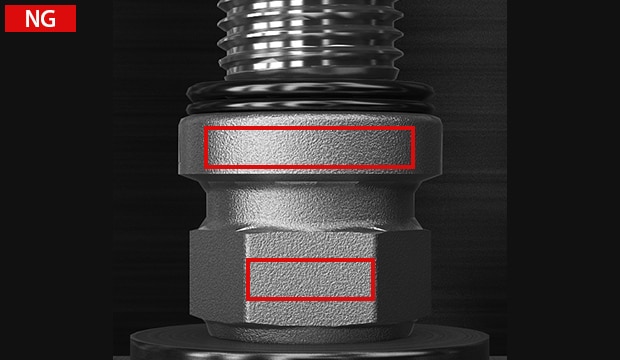

Automotive/Metal industries Spark Plug Marking Checking

Reliably checking for marking on spark plugs is possible even for targets with troublesome surface conditions.

Electrical/Semiconductor industries Confirmation of Printing on Wafers

The IV4 Series can identify engraved characters on wafers and ensure reliable detection even with SEMI standard fonts.

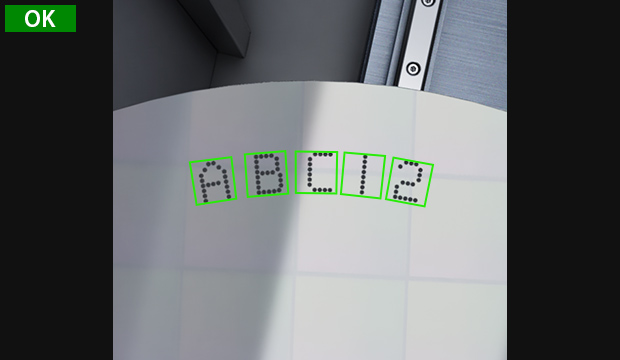

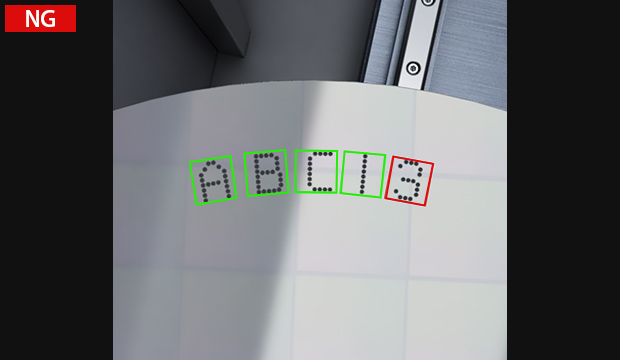

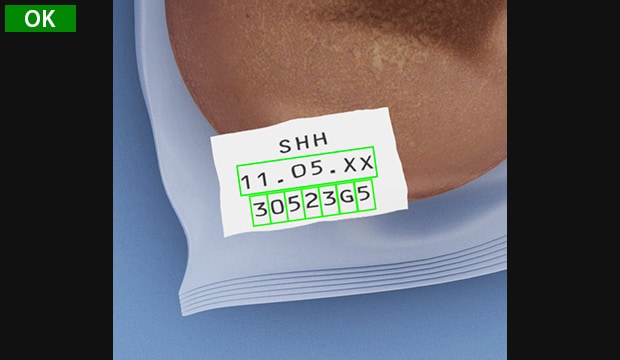

Packaging/Food/Pharmaceutical industries Best-Before Date Printing Check

Checking expiration dates is possible even if the bag is tilted or wrinkled.

Count-Based Identification

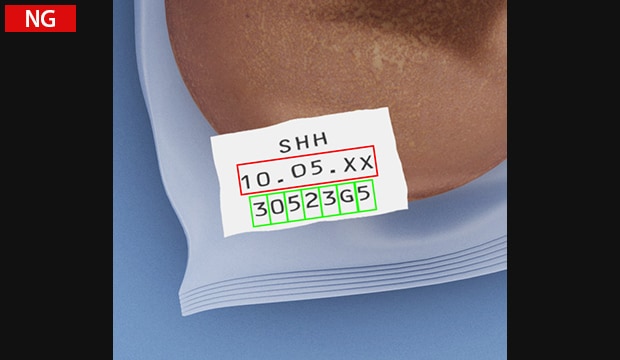

Packaging/Food/Pharmaceutical industries PET Bottle Count Checking

The IV4 Series can check for missing PET bottles by counting the number of bottles in the case.

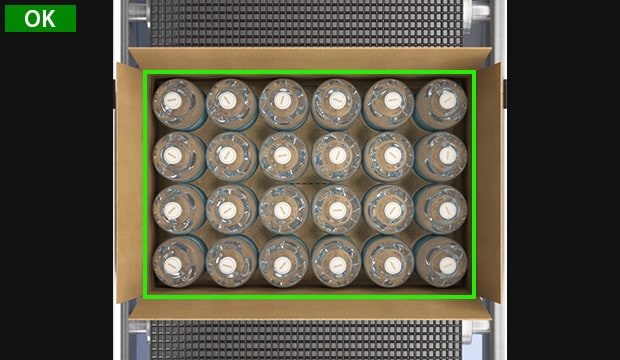

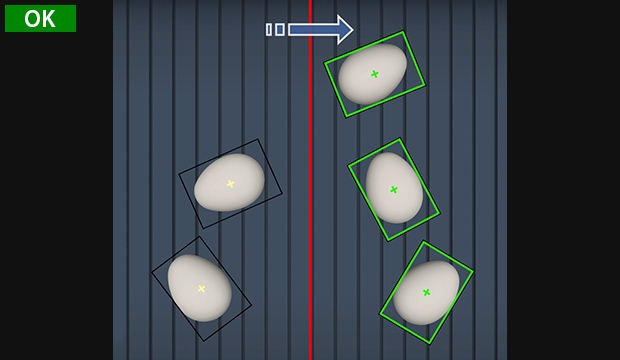

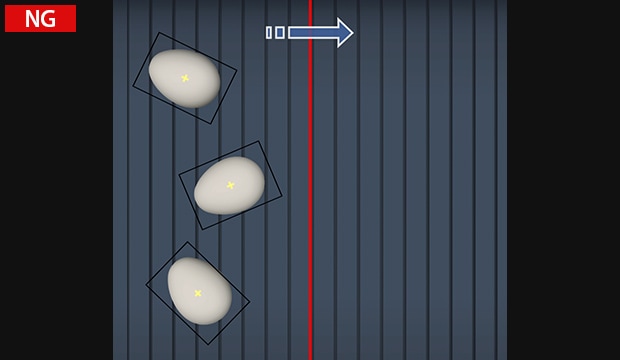

Packaging/Food/Pharmaceutical industries Quantity Check for Egg Shipments

Reliable counting of eggs passing on a conveyor is possible regardless of the position or orientation of the eggs.

3 pcs

0 pcs

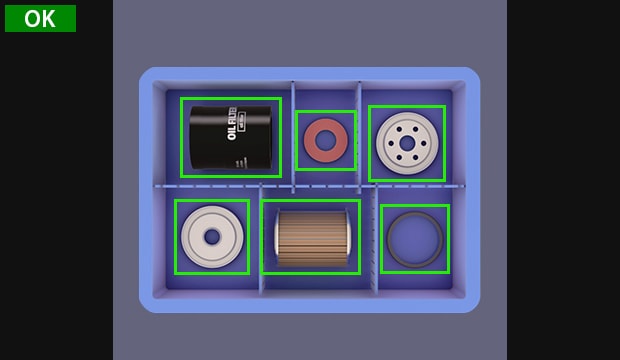

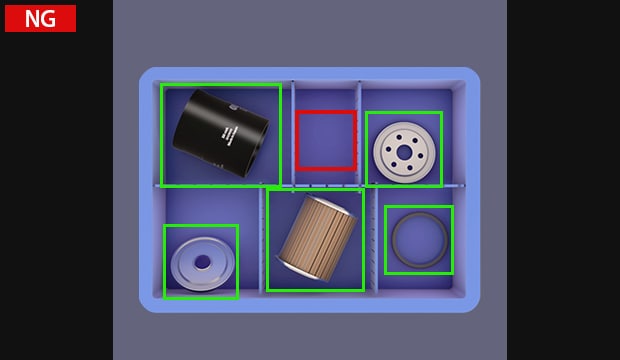

Automotive/Metal industries Parts Check Before Oil Filter Assembly

Kitting inspections are possible to ensure the correct parts are included in packages, with accurate counting even if the position and orientation of the parts vary.