High-Accuracy High-Speed Sensing Ionizer

SJ-Q series

High-Accuracy High-Speed Sensing Ionizer SJ-Q series

New High-performance Static Elimination with No Maintenance Required

- Maintenance-free elimination with new Inside Supersonic probe structure

- Ion balance +/- 3 V means highly reliable static elimination

- Reduce static as quickly as possible with a static elimination speed of 0.1 sec

The High-Accuracy High-Speed Sensing Ionizer SJ-Q Series provides 10 times the static elimination performance of conventional models (ion balance: ±3 V, static elimination speed: 0.1 s). This greatly reduces conventional static eliminator problems: risks as well as time and effort related to electrode probe cleaning and wear. This product provides completely maintenance-free reliable static elimination. Conventional electrode probes must be replaced every 1 to 2 years, but with this product they do not need to be replaced for 10 years. The electrode probe cleaning that had to be performed every 2 to 4 weeks also only needs to be performed once a year. The result is a major decrease in ionizer running costs. The world’s first Inside Supersonic structure will change the way you think about static electricity countermeasures.

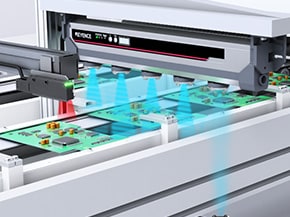

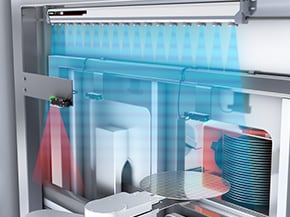

Applications

Features

Maintenance-Free

No Electrode Probe Replacement Required for 10 Years

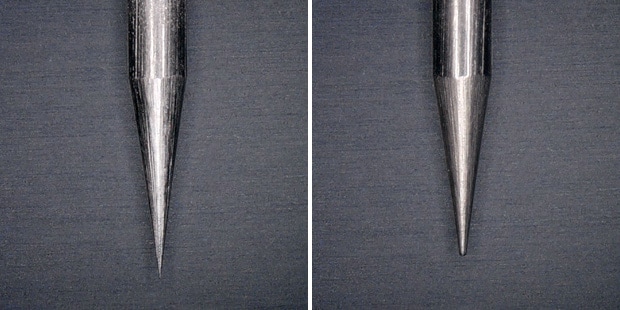

Accurate static elimination is provided even with probe wear. The Hi-Power I.C.C. system monitors the ion generation status at all times. The applied voltage is automatically increased as the probe wears down.

Operating period and static elimination time

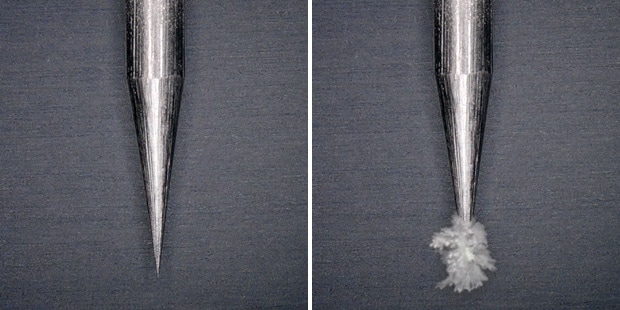

Left: New electrode probe

Right: Worn electrode probe

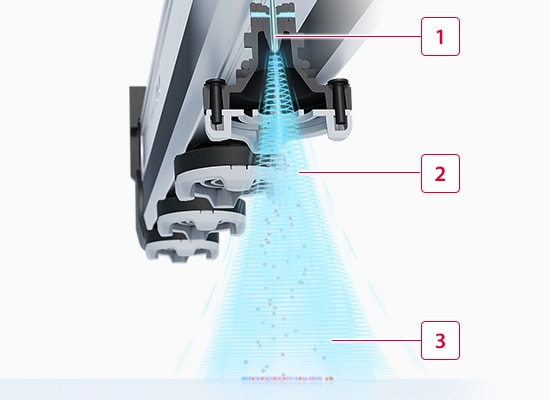

No Electrode Probe Cleaning Required for 1 Year*

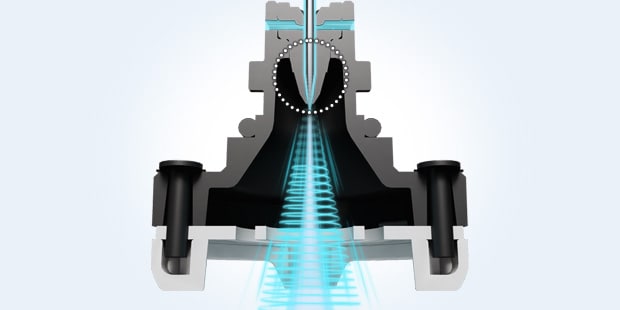

Probes are protected from dust and other debris to provide accurate static elimination for as long as possible. Supersonic air is sprayed coaxially onto the electrode probe, enveloping it and repelling dirt from outside air.

* The cleaning frequency may be higher depending on the usage environment.

Inside Supersonic structure

Left: New electrode probe

Right: Dirty electrode probe

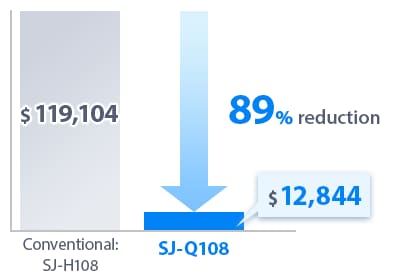

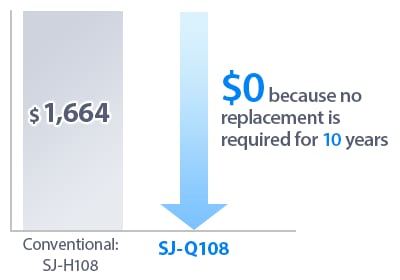

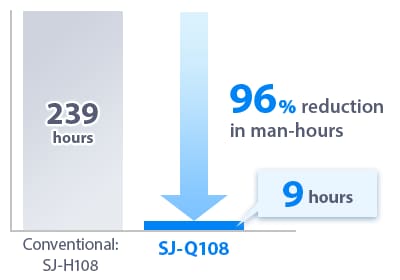

Reduced Operating Costs Over 10 Years of Use

* Annual electricity bill calculated at 0.18 $/kWh. Comparison of simulations when supplying 0.5 MPa 72.52 PSI CDA to the SJ-Q108 for 10 years and 0.5 MPa 72.52 PSI CDA to the conventional SJ-H108 for 10 years.

Example of Factory Air Costs for Ionizers

Example of Electrode Probe Costs

Example of Labor Hours Required for Cleaning Electrode Probes

A World First High-Speed Static Elimination as Fast as 0.1 Sec

The Inside Supersonic structure allows for faster static elimination than conventional models.

Not only does this reduce static elimination time, but also makes it possible for a single unit to handle targets being transported at high speeds, which conventionally required multiple units.

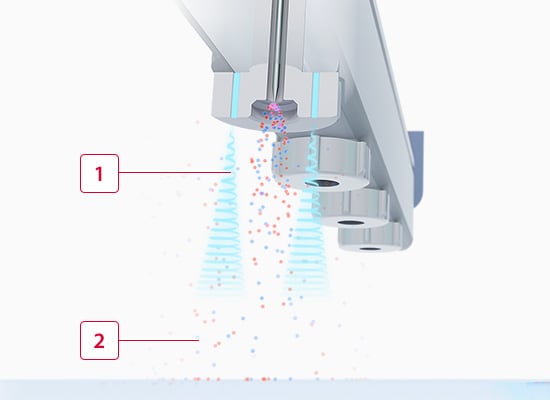

Standard Ionizer

Required ions do not reach their target

-

1Slow air

-

2Neutralized ions

SJ-Q Series

Ultra-high-speed coaxial air

Required ions reach their target

-

1Inside Supersonic structure

-

2Fast air

-

3Ions reach the target without being neutralized

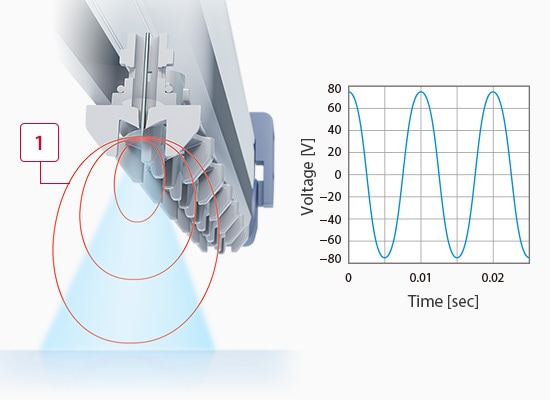

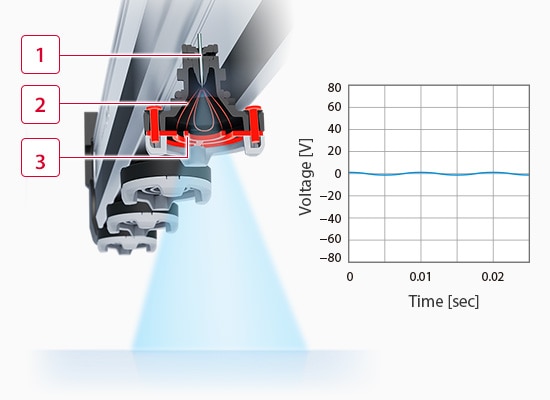

A World First Ion Balance ±3 V

The effect of the electric field from the electrode probe is reduced, minimizing voltage swing.

The result is an ion balance 10 times better than conventional models, enabling highly accurate static elimination and minimizing problems caused by electrostatic damage and the risk of foreign contamination.

General-Purpose Ionizer

Voltage of target fluctuates due to electric field

-

1Electric field affects target

SJ-Q Series

Electric field shielding technology

Almost no fluctuation as there is no electric field

-

1Inside Supersonic structure

-

2Confined electric field cannot affect target

-

3GND plate

Safety Bar Type Ionizer

A Safe Bar-Type Ionizer That Does Not Give Off a Discharge Even if Touched

Increased Safety With the Inside Supersonic Mechanism

The tip of the electrode probe is covered by a GND plate, so it won't give off a discharge even if touched. You can use this device safely and with confidence of reduced risk of any discharge occurring when contact is made with the ionizer during maintenance or equipment inspections.