Digital Microscopes

Observation and Measurement of Aerosol Spray Dispensers Using Digital Microscopes

An aerosol spray dispenser, also known as an aerosol spray can, is a container product that is filled with a propellant and a liquid and expels them in the form of mist or foam using the pressure of the propellant. Aerosol spray dispensers are used in a wide range of daily use items such as cosmetic hair spray, hair mousse, pesticides, and air fresheners. This section introduces examples of observation of aerosol spray dispensers using digital microscopes.

Advantages and Disadvantages of Aerosol Spray Dispenser Products

Aerosol spray dispenser products, which use gas pressure, have the following advantages and disadvantages.

Advantages of aerosol spray dispenser products

- Easy to use by simply pressing a button.

- Easy to carry around.

- Long-term storage is possible because contents do not become oxidized.

- Safe and sanitary due to dirt-free structures.

- Just the necessary amount can be used.

- It is possible to create finer mist or foam than pump-type dispensers.

Disadvantages of aerosol spray dispenser products

- Containers may burst when left in locations exposed to high temperatures.

- The gas pressure reduces at low temperature, preventing contents from being discharged powerfully.

- Aerosol spray dispensers need to be separated when they are discarded.

- Contents may be left inside when the gas is exhausted first.

Get detailed information on our products by downloading our catalog.

View Catalog

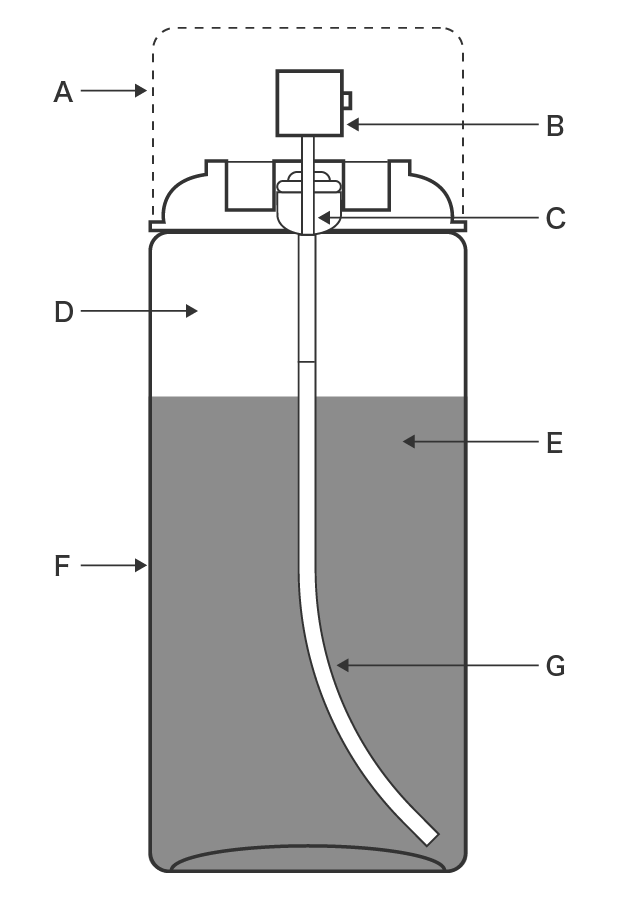

Aerosol Spray Dispenser Structure

Liquefied petroleum gas (LPG), dimethyl ether (DME), nitrogen (N2), carbon dioxide (CO2), or a similar gas is used as the propellant and a liquid is sprayed using its pressure.

A : Cap

B : Button

C : Valve

D : Propellant vapor (gas layer)

E : Propellant and liquid (liquid phase)

F : Pressure-resistant container

G : Dip tube

We’re here to provide you with more details.

Reach out today!

Differences between Products Shaken/Not Shaken Before Use

Some aerosol spray dispenser products are shaken before use and the others are not, which is determined by the type of liquid and propellant used.

Products shaken before use:

- Products that use liquefied petroleum gas (LPG) or dimethyl ether (DME) as the propellant

- Products in which the propellant does not dissolve in the liquid and thus there are three separate phases

- Products that contain an emulsified liquid

- Products that contain a liquid mixed with powders

Products not shaken before use:

- Products that use a compressed gas, such as nitrogen gas (N2) and carbon dioxide (CO2), as the propellant

We’re here to provide you with more details.

Reach out today!

Differences between Products That Can/Cannot Be Used Upside Down

Some aerosol spray dispensers have a structure that cannot be used upside down, while others have a structure that needs to be used upside down. There are also aerosol spray dispensers that can be used both upright and upside down.

Products that cannot be used upside down:

- Products that spray a contained liquid through a dip tube

This structure cannot be used upside down because the dip tube tip enters the propellant gas layer.

Products used upside down:

- Products that do not have a dip tube

This structure cannot be used upright because the propellant gas layer is on top.

Products that can be used upright and upside down:

- Products in which the dip tube is weighted.

The dip tube tip is always immersed in the liquid phase. - Products that have a mechanism to discharge a contained liquid not only from the dip tube but also from the hole on the valve side wall (vapor tap)

We’re here to provide you with more details.

Reach out today!

Observation and Measurement Examples of Aerosol Spray Dispensers Using Digital Microscopes

These are the latest examples of observation and measurement of aerosol spray dispensers using KEYENCE’s VHX Series 4K Digital Microscope.

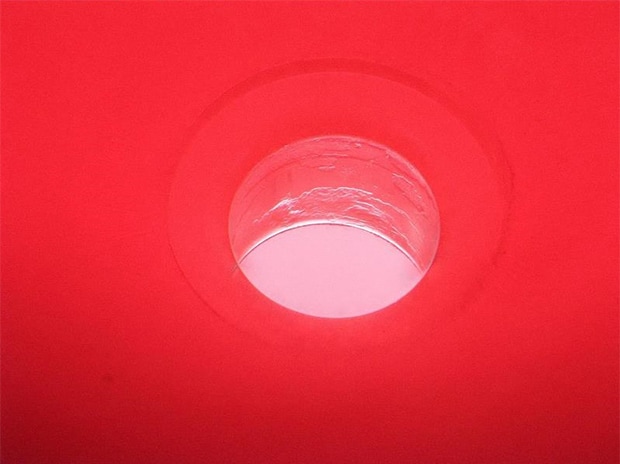

Tilted observation of a spray nozzle

VH-Z20, 200×, ring illumination

VH-Z20, 200×, ring illumination + backlight

Combination with a backlight allows for observation of the internal walls of nozzles.

Observation of a fracture spray nozzle surface

Using the HDR function allows for observation without glare.

An adjustable illumination attachment can be used to emphasize fracture surface irregularities.

ZS-20, 50×, coaxial illumination, normal image

ZS-20, 50×, image of coaxial illumination + HDR + adjustable illumination attachment

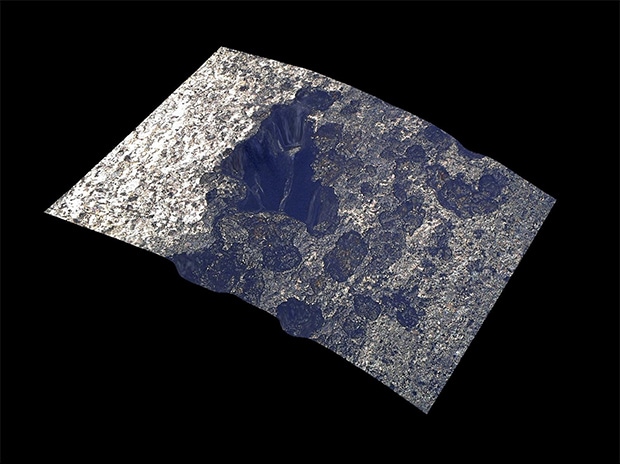

Corrosion condition observation of an aerosol spray can

Using the depth composition function allows for the inside of corrosion to be checked.

ZS-200, 300×, coaxial illumination

2D image

ZS-200, 300×, coaxial illumination

3D image

ZS-200, 300×, coaxial illumination

Curvature observation of a coated surface of aerosol spray dispenser

Get detailed information on our products by downloading our catalog.

View Catalog