Digital Microscopes

Observation and Measurement of Molds and Dies Using a Digital Microscope

Molds and dies are tools that are essential to mass production in present-day manufacturing. Both are key elements in manufacturing―for example, molds are used in injection molding to shape resin as well as in casting, and dies are used in stamping.

This section introduces observation and measurement examples of molds and dies using a digital microscope.

Advantages and disadvantages of using molds/dies

Advantages

- Fast mass production of products with the same shape.

- High-accuracy production with low variation.

- No special skills required with anyone able to perform operations easily.

- Minimal material waste and low processing costs.

Disadvantages

- Mold/die fabrication can be costly and time-consuming.

- High level of skill and experience required for mold/die fabrication.

Get detailed information on our products by downloading our catalog.

View Catalog

Types of molds/dies

Molds and dies are tools used to form and shape materials.

Dies are “open” in that they consist of top and bottom pieces that are not sealed.

Molds, on the other hand, are “closed”, and materials such as metal and resin are poured into a cavity to form a finished product.

Dies

- Press dies

Press dies are used to shape automobile bodies and other components. These are the most common type of die. Press dies can also be further categorized into punch dies, bending dies, and compression dies. - Forging dies

These dies are used to shape drive components for automobiles and other vehicles. The dies are used to hit a material and create a different shape. Parts requiring high strength are usually made with forging dies. There are two main forging methods: Hot forging, when the material is heated and softened before being struck, and cold forging, when the material is struck at room temperature.

Molds

- Molds for injection molding

These molds are used for molding plastic parts. A plastic material is heated in a heating cylinder and then pressurized and injected into a mold. The plastic then cools and solidifies. - Molds for die casting

Die casting molds are used for molding by injecting molten aluminum, magnesium, or other material into a mold under high pressure. This makes it possible to mass-produce casting products with high accuracy and high-quality surface conditions at high speeds. The term “die casting” is generally used to refer to both the casting method and the molded product. - Casting molds

Casting is done by heating cast iron, aluminum alloys, copper, brass, or other materials to high temperatures until they melt, and then pouring the molten material into a mold. The mold used for casting is called a casting mold, and the resulting product is called a casting. - Powder mold

Powder molds are used to form products by compressing and then hardening a metal powder.

We’re here to provide you with more details.

Reach out today!

Mold/die machining methods

- Cutting

Molds and dies can be machined using an edged tool to cut away the surface of a material. This cutting is most commonly done in a machining center. - Grinding

Grinding bits can also be used to machine molds and dies. This method makes it possible to machine hard materials that cannot be machined by cutting, including hardened steel and cemented carbide. Compared with cutting, this method allows for machining with higher accuracy and is commonly used for finishing. However, grinding also takes longer. - Wire electrical discharge machining

Wire electrical discharge machining is a method that uses brass wires to cut metal. With this method, machining is possible regardless of the hardness of the metal, enabling machining of hardened steel materials, cemented carbides, and other metals.

We’re here to provide you with more details.

Reach out today!

Observation and measurement examples of molds and dies using a digital microscope

The latest examples of observation and measurement of molds and dies using KEYENCE’s VHX Series 4K Digital Microscope are introduced below.

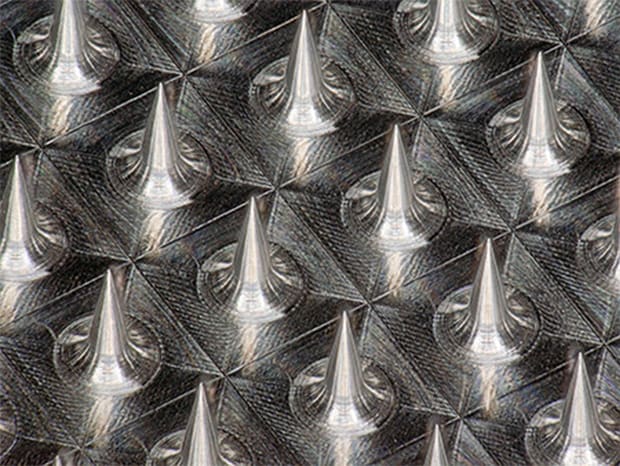

Depth composition image of a microneedle mold

VH-Z20, 100×, ring illumination

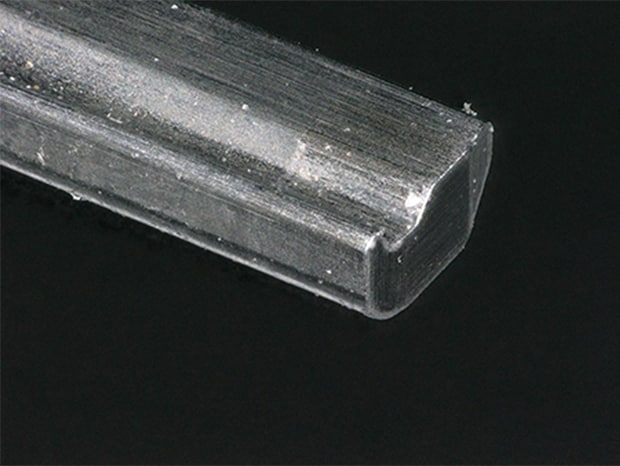

Depth composition image of a punch die

VH-Z20, 100×, ring illumination

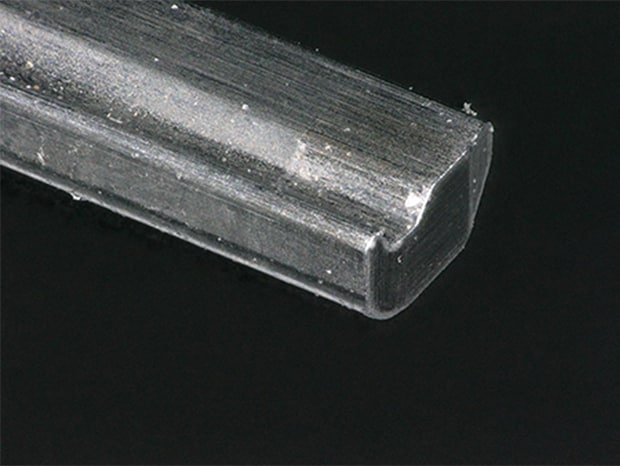

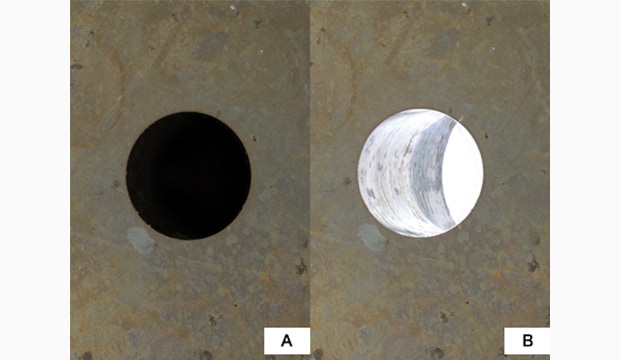

Observation image of the inner wall of a mold

VHX-E20, 20×

A: Without backlight B: With backlight

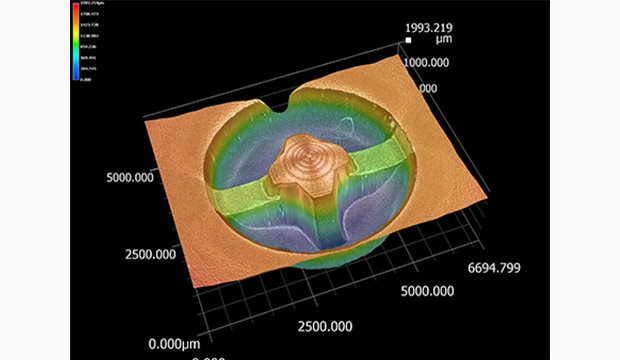

3D image of a screw mold

ZS-20, 50×, ring illumination

Comparison image of the surface texture of a product

ZS-200, 1500×, coaxial illumination

Managing wear is possible by measuring products in 3D.

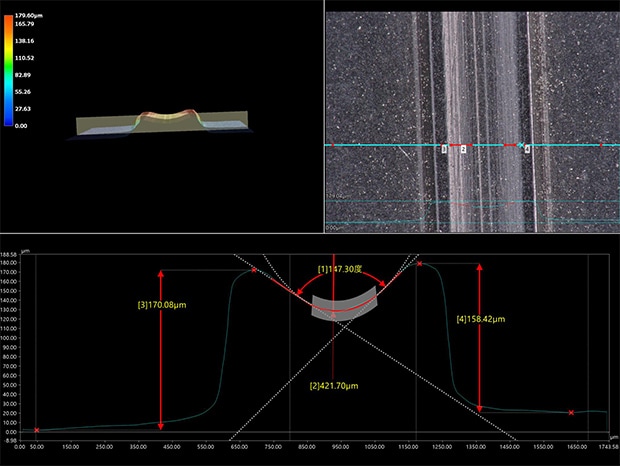

3D measurement image of the cutting edge of a die

VH-Z20, 200×, ring illumination

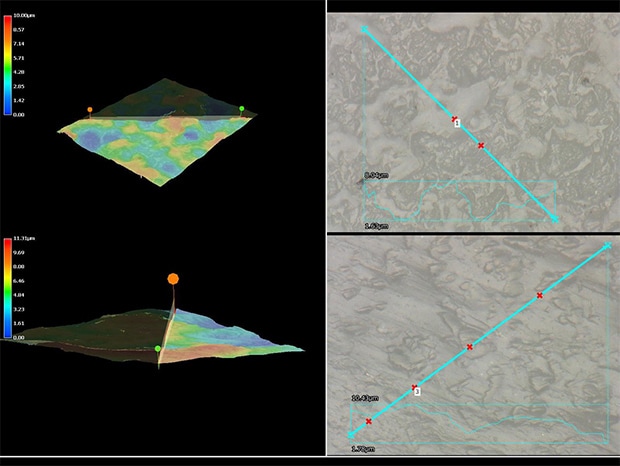

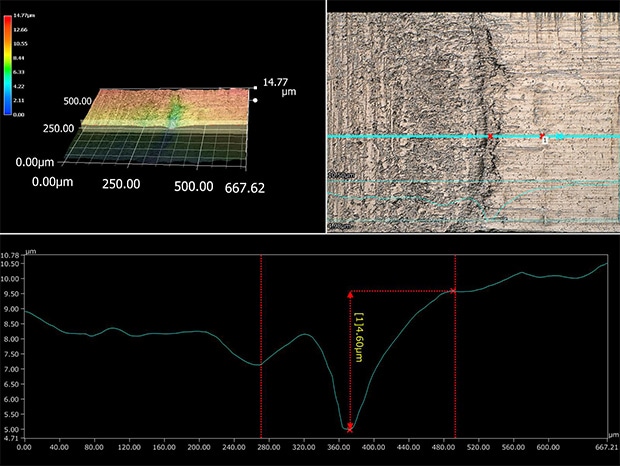

3D measurement image of surface defects

ZS-200, 500×, coaxial illumination

Defects that cannot be captured with a roughness meter can be clearly identified.

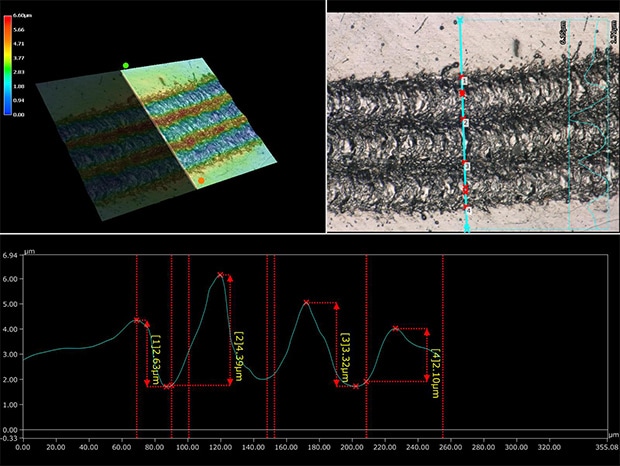

3D measurement image of marking on a mold

ZS-200, 1000×, coaxial illumination

Observation image of the sliding parts of a mold

VH-Z20, 100×, ring illumination (normal image)

Optical Shadow Effect Mode image

Optical Shadow Effect Mode can be used to visualize microscopic irregularities.

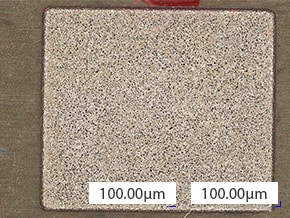

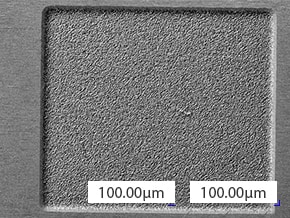

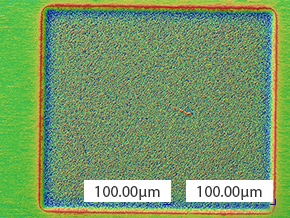

Surface observation image after electrical discharge machining

VHX-E20, 50×, ring illumination (normal image)

Optical Shadow Effect Mode image

Optical Shadow Effect Mode can be used to visualize satin surface patterns.

Optical Shadow Effect Mode color map image

Get detailed information on our products by downloading our catalog.

View Catalog