Digital Microscopes

Cutting Tool Types and Observation and Inspection Using a Digital Microscope

The pursuit of higher strength, greater accuracy, and lighter weight has led to increasing demand for workpieces in difficult-to-cut shapes made from hard-to-cut materials, such as cemented carbide, hard brittle materials, and quenched stainless steel. Hard-to-cut materials put a large strain on cutting tools, so particular attention is required to monitor wear and chips (defects) on the edges of cutting tools. This section introduces types of cutting tools along with examples of observing and analyzing them using our digital microscope.

What is Cutting?

Cutting refers to processing that cuts metal and other materials using tools such as blades.

Another metal processing method, called grinding, scrapes surfaces using a grindstone.

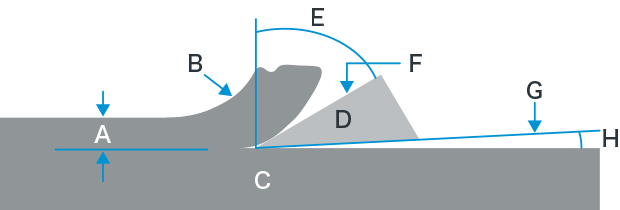

A: Uncut chip B: Chip C: Workpiece D: Tool E: Rake angle F: Rake surface G: Relief surface H: Relief angle

Principle of cutting

A cutting tool continuously chips the target material and generates chips.

In the ideal scenario, chips are generated in a continuous and smooth manner.

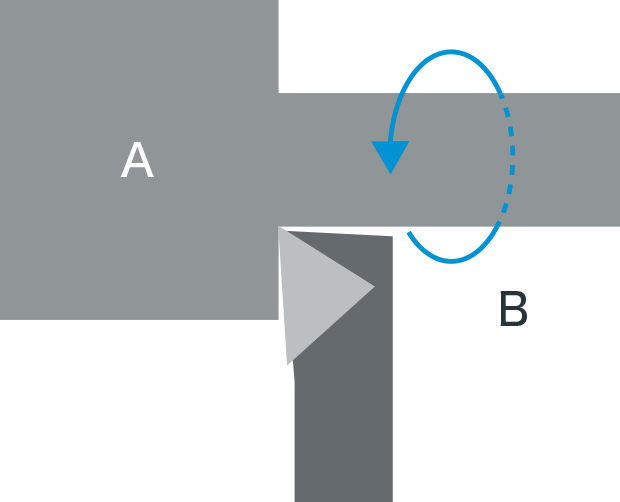

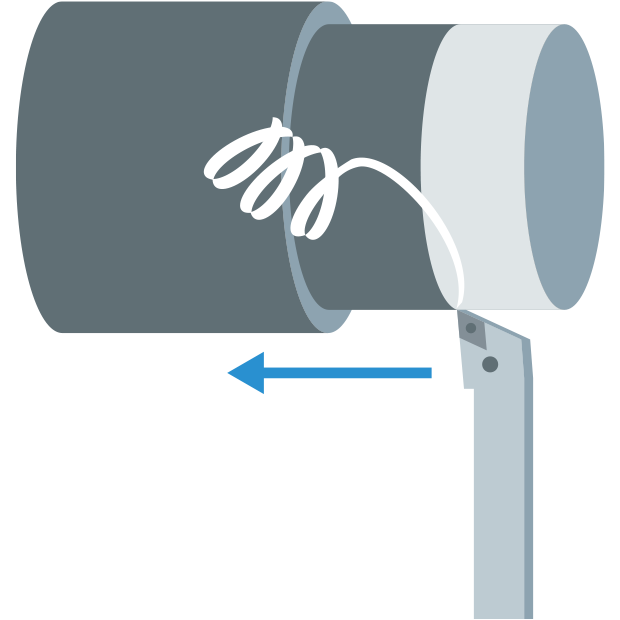

A: Workpiece B: Distance cut per minute

Cutting conditions

The cutting speed, feed speed, and cut amount are all important factors for proper cutting.

Cutting speed = Distance cut per minute (m/min)

Cutting speed (m/min) refers to the distance that a tool cuts per minute.

The faster the cutting speed, the higher the productivity, but the shorter the service life of the tool.

The faster the cutting speed,

the higher the productivity,

but

the shorter the service life of the tool.

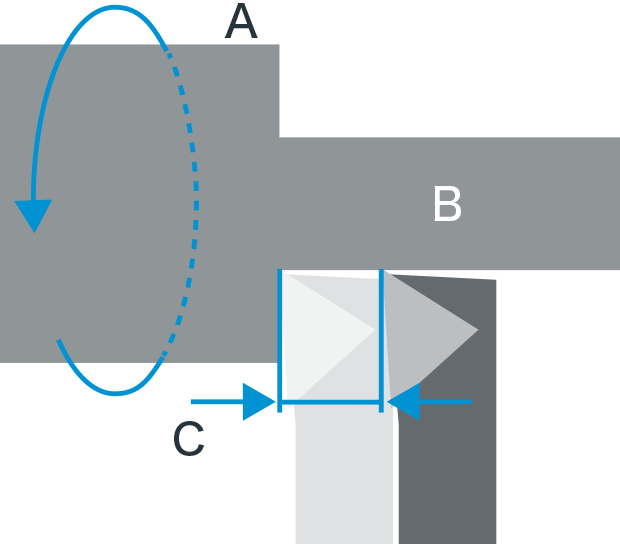

A: One revolution B: Workpiece C: Distance travelled per revolution

Feed speed = Distance to travel per revolution (mm/rev)

The feed speed (mm/rev) refers to the distance that a tool travels per revolution.

As the feed speed increases, productivity increases but so does the roughness of the cut surface.

As the feed speed increases,

productivity increases

but

so does the roughness of the cut surface.

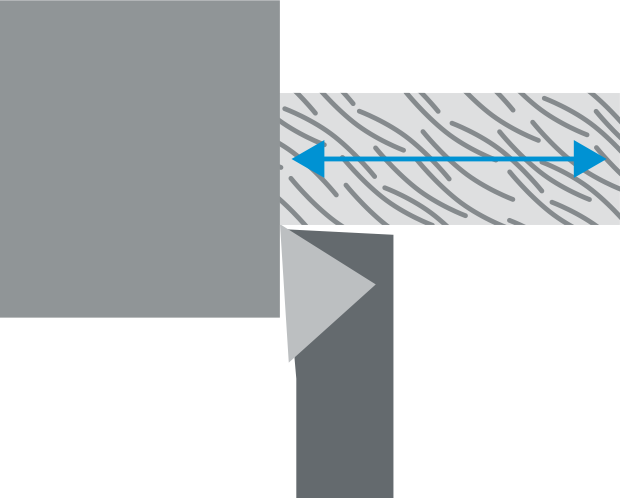

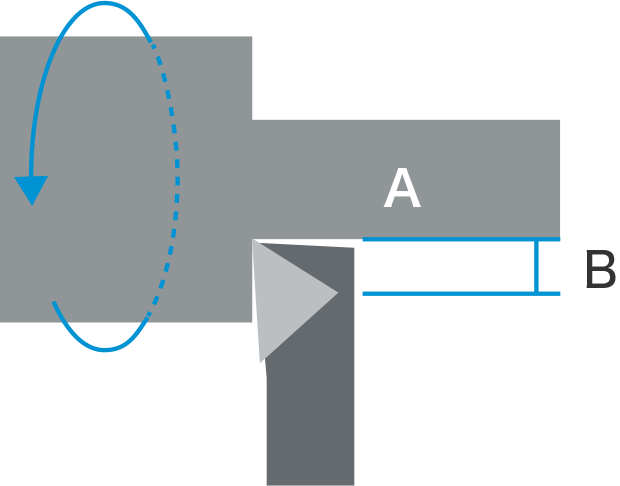

A: Workpiece B: Cut amount

Cut amount = Distance to cut into the workpiece

The cut amount refers to the distance that a tool cuts into the workpiece.

The greater the cut amount, the higher the productivity, but the ideal cut amount is determined by the type and material of the tool.

The greater the cut amount,

the higher the productivity,

but

the ideal cut amount is determined by the type and material of the tool.

Get detailed information on our products by downloading our catalog.

View Catalog

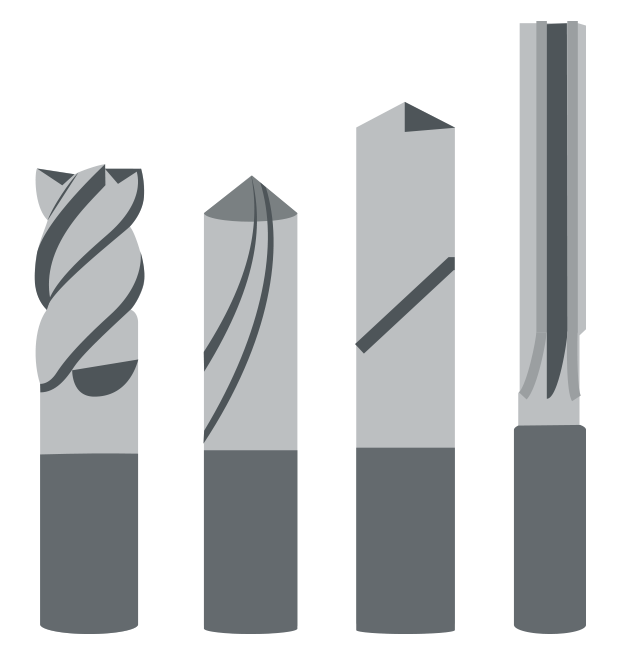

Typical Cutting Methods and Cutting Tools

This section describes typical cutting methods, their characteristics, and the cutting tools that are used.

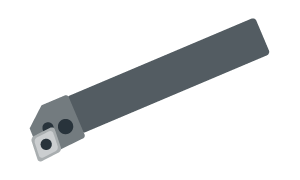

- Turning

Generally, this method cuts cylindrical or discoidal workpieces into round shapes by turning them.

Machine name: Lathe

Cutting tool: Tool bit

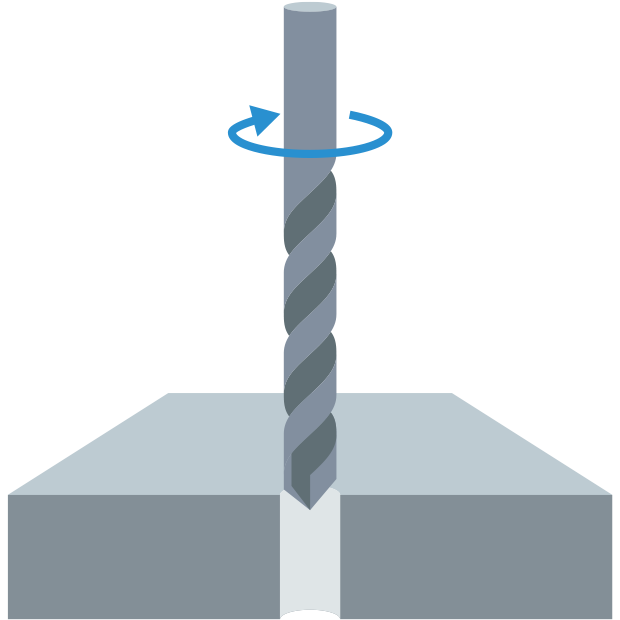

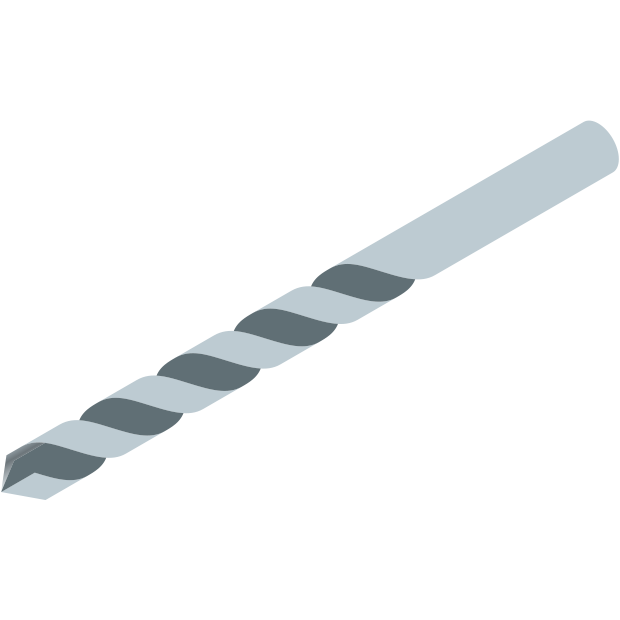

- Drilling

Tools rotate to make holes in surfaces of workpieces.

Machine name: Drilling machine

Cutting tool: Drill

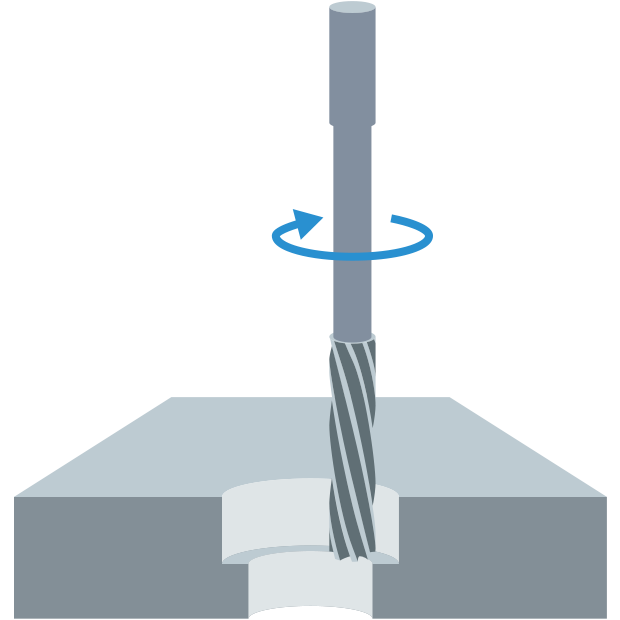

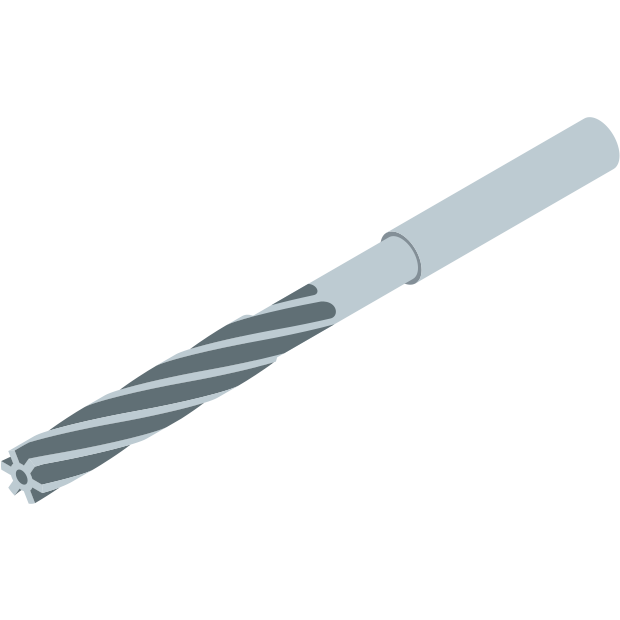

- Boring

Tools rotate and machine the inside of drilled holes with high accuracy.

Machine name: Boring machine

Cutting tool: Reamer

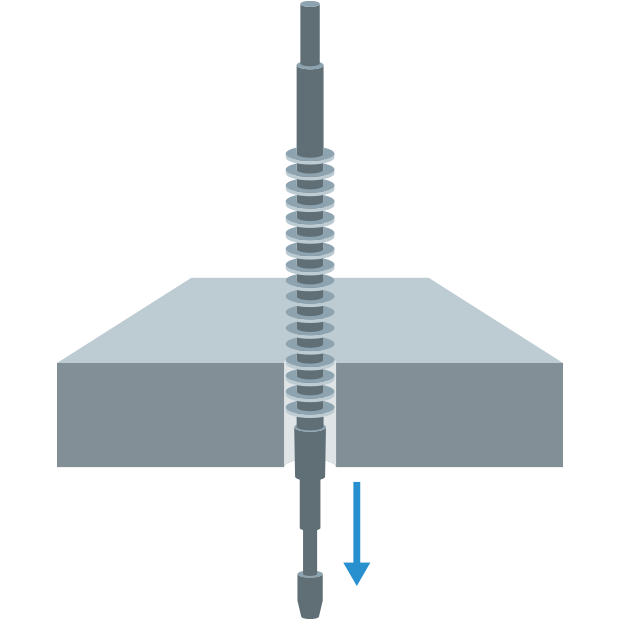

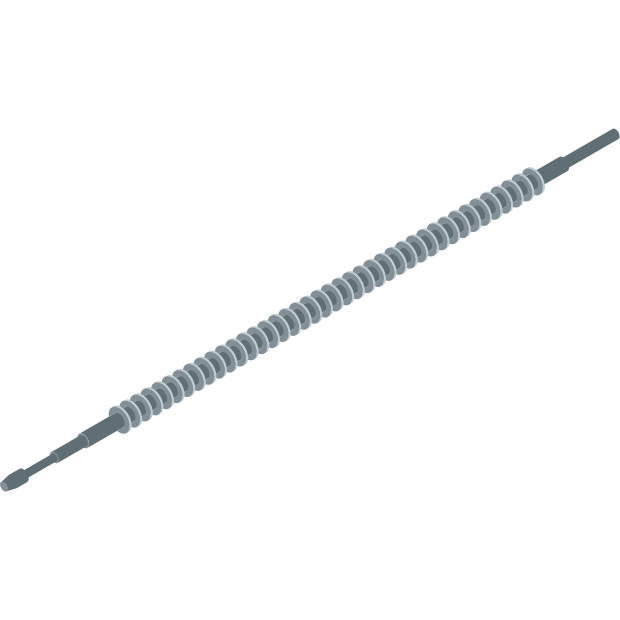

- Broaching

Broaches (tools to finish holes) cut workpieces by moving linearly. Broaching can perform a whole process (through to finishing) with one machine, and it’s easy to estimate the service life of tools. These factors make broaching attractive to the automotive industry where mass production is necessary.

Machine name: Broaching machine

Cutting tool: Broach

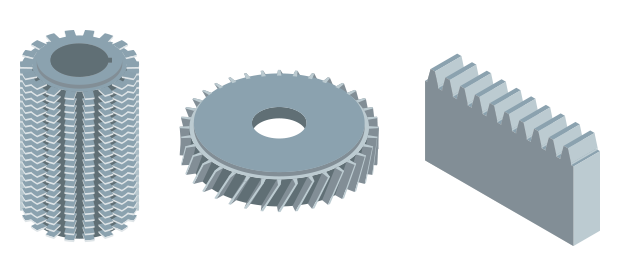

- Gear cutting

Gears are cut with a rotating cutter.

Machine name: Gear cutting machine

Cutting tool: Hob cutter, pinion cutter, rack cutter

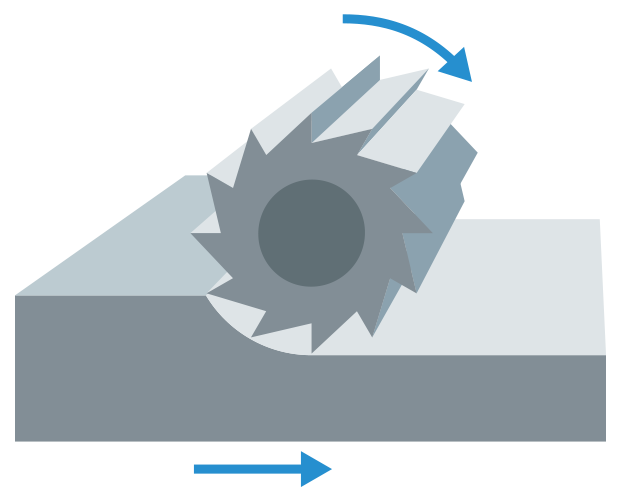

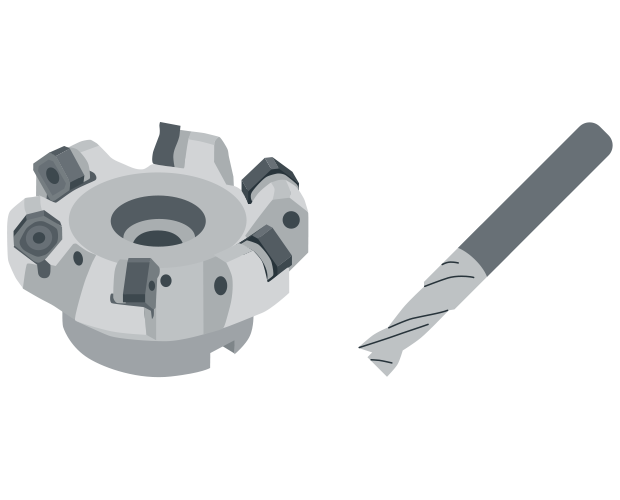

- Milling

Milling removes material by turning a tool called a milling cutter. Milling machines are used to shave surfaces and make grooves. There are generally 2 types: face milling cutters for surface machining, and end mills for grooving.

Machine name: Milling machine

Cutting tool: Face mill, end mill

We’re here to provide you with more details.

Reach out today!

Typical Tool Materials and Features

This section describes the materials and features of typical cutting tools.

- High-speed steel

Metals, including tungsten, chromium, vanadium, and molybdenum, alloyed with an iron base

Advantage Excellent toughness

Disadvantages Lower heat and wear resistance

Target materials: Carbon and alloy steel - Cemented carbide

Alloys of titanium carbide and tantalum carbide that are added to tungsten carbide powder and then sintered using cobalt.

Advantages Excellent balance of toughness, high hardness, and wear resistance

Target materials: Carbon steel, alloy steel, stainless steel, and other cutting resistant materials - Ceramic

Hard materials, including aluminum oxide, titanium carbide, and silicon nitride, that are sintered.

Advantages Excellent heat and wear resistance

Disadvantages Poor toughness and chip easily

Target materials: Cast iron, heat-resistant alloys, quenched steel, and tool steel - Diamond

Molded material made from diamond monocrystal (the hardest material)

Advantages Excellent heat and wear resistance, and suitable for mirror face cutting

Disadvantages Poor toughness and chips easily

Target materials: Non-ferrous metals including aluminum - Sintered diamond

Polycrystalline body made by adding cobalt to fine diamond powder and sintering.

Advantages Excellent heat and wear resistance, and higher toughness than diamond

Disadvantage Hard to make sharp edges

Target materials: Non-ferrous metals, cemented carbide, ceramics - Cermet

Nickel and other materials are added to titanium carbide and titanium nitride and then sintered.

Advantages A type of cemented carbide. Excellent wear and corrosion resistance compared with normal cemented carbide. It is often used for finishing steel.

Target materials: Carbon and alloy steel

We’re here to provide you with more details.

Reach out today!

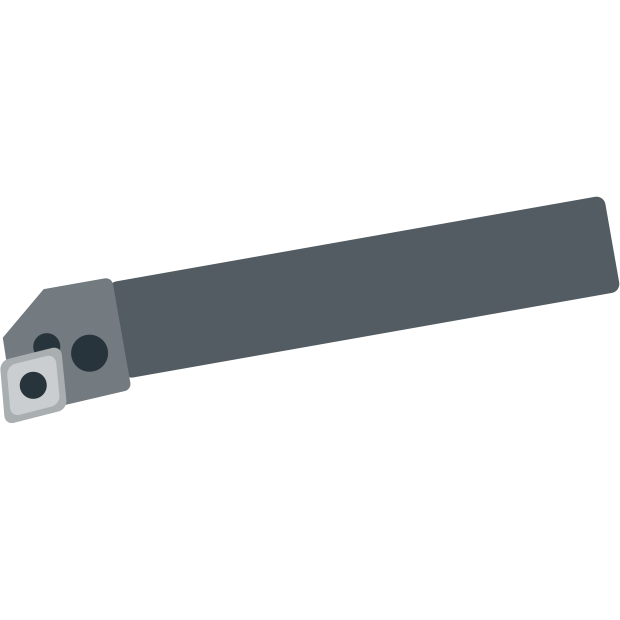

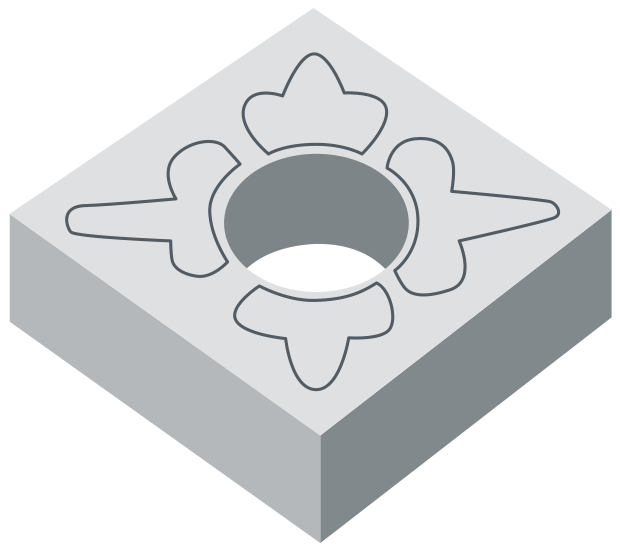

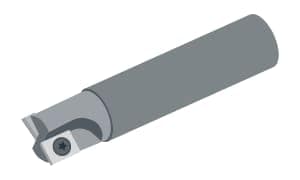

Throwaway Tips

The benefit is that the edge is replaceable and it can be used immediately after replacement.

Throwaway tips are mechanically fixed in holders with screws before use. The material for the edge is generally cemented carbide and the shapes are defined by the ISO (e.g., equilateral triangle, square, rhomboid, and circle).

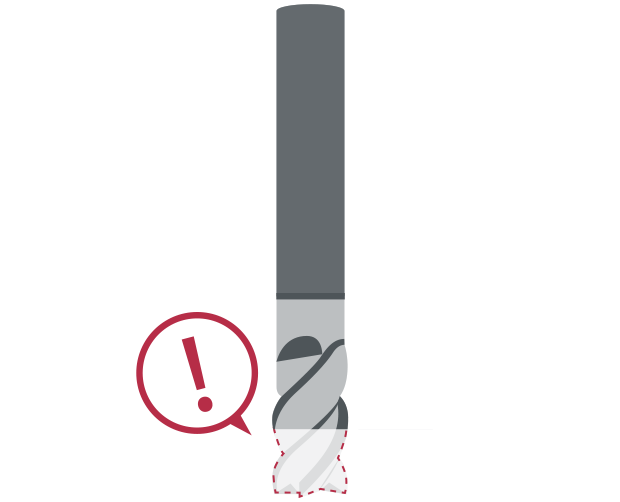

End mill

Face mill cutter

Tool bit

We’re here to provide you with more details.

Reach out today!

Examples of Observation and Inspection of Cutting Tools Using a Digital Microscope

The latest examples of observation and inspection images of cutting tools using KEYENCE’s VHX Series 4K Digital Microscope are introduced below.

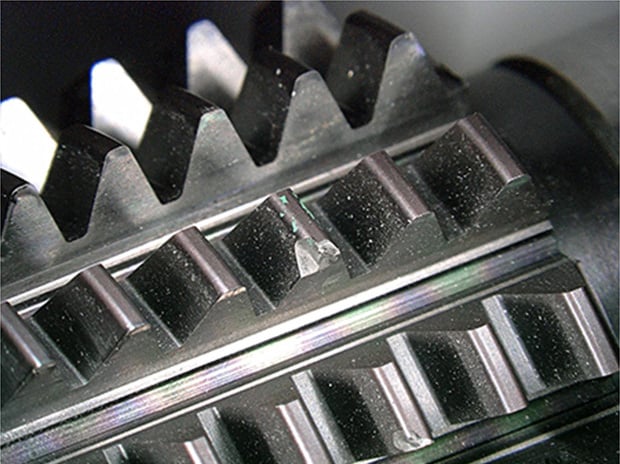

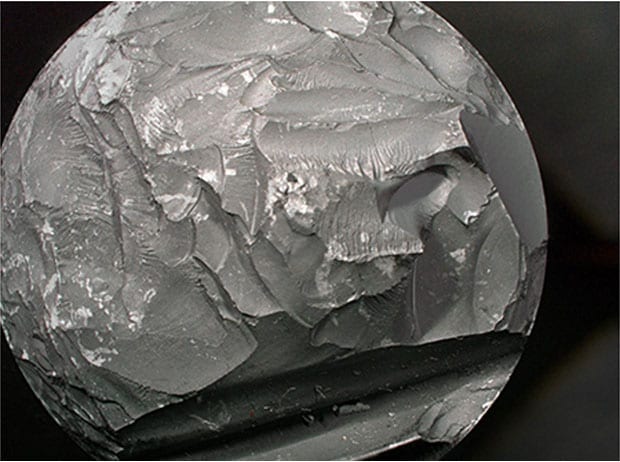

Chipping on a hob cutter edge

20×, ring illumination

100×, ring illumination

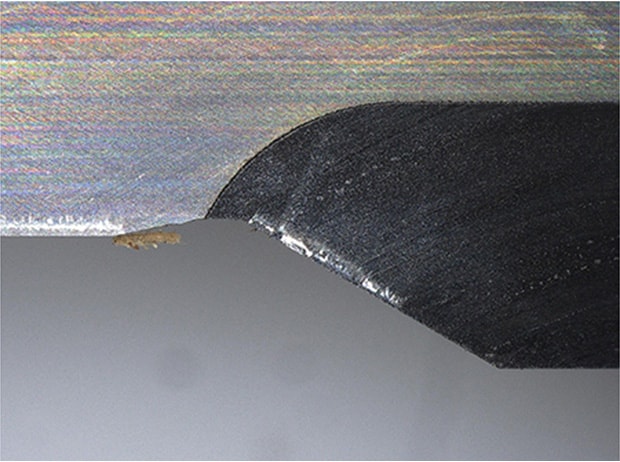

Pinion cutter wear, coating peeling

20×, ring illumination

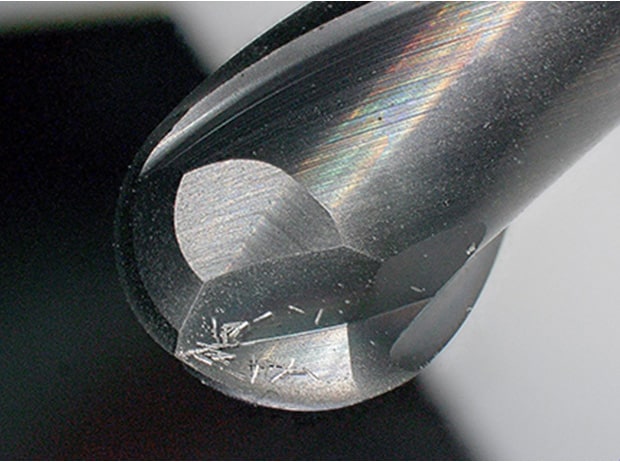

Observation of a reamer edge

20×, ring illumination

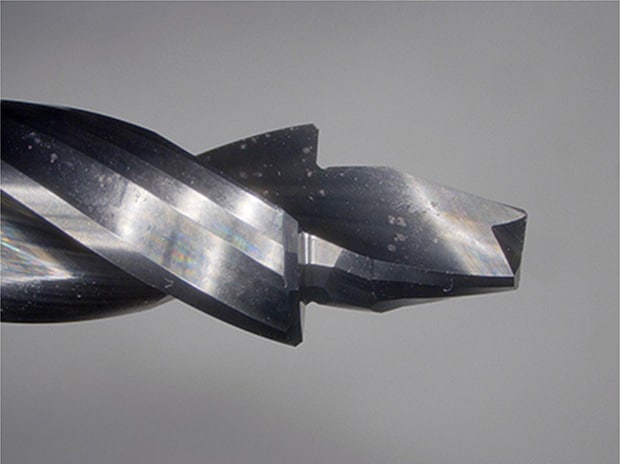

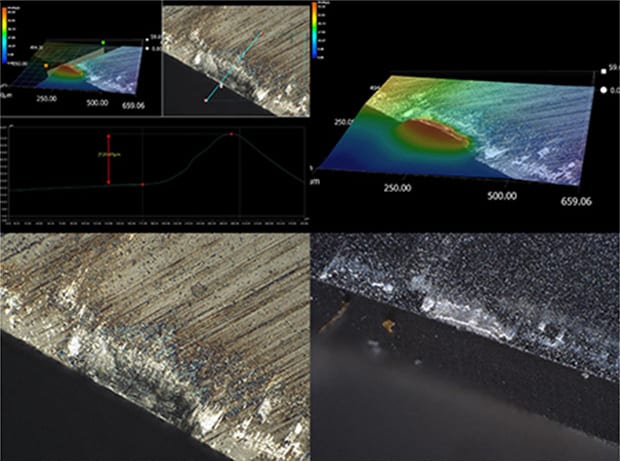

Observation of drill wear

50×, ring illumination

3D image

200×, ring illumination

Observation of edge wear

1000×, coaxial illumination

Observation of edge wear

300×, multi-lighting

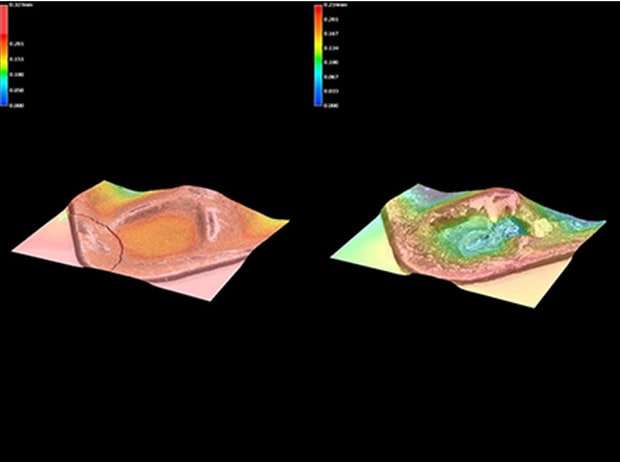

Observation of edge wear, 3D comparison image

150×, ring illumination

Observation of chip adhesion

30×, ring illumination

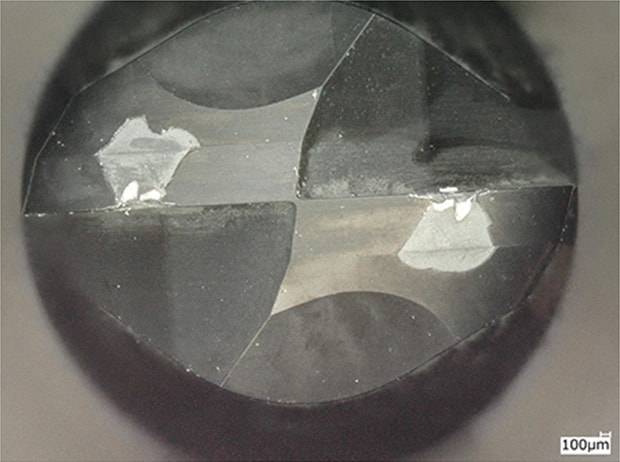

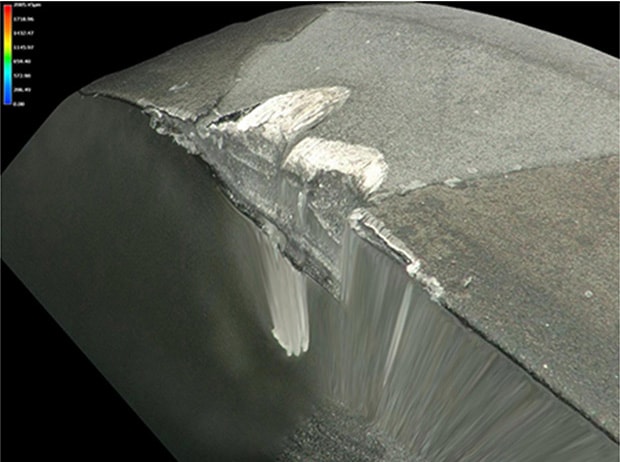

Observation of edge adhesion

3D observation showed that what was thought to be chipping was actually adhesion.

Low magnification at 50×, ring illumination

3D image at 500×, coaxial illumination

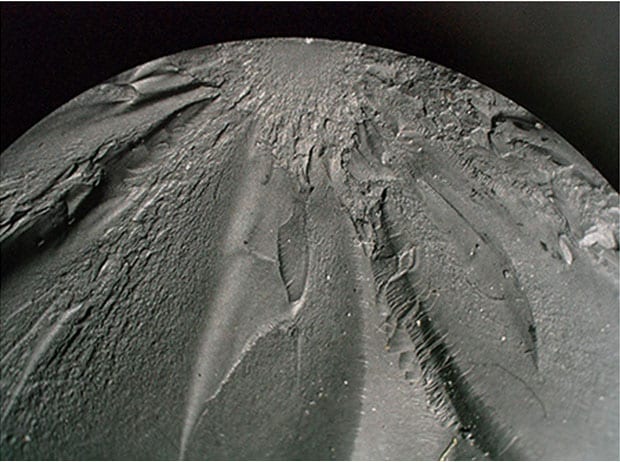

Observation of the point at which the tool started to break

Multi-lighting allows easy observation of the starting point of a fracture surface.

20×, multi-lighting

30×, multi-lighting

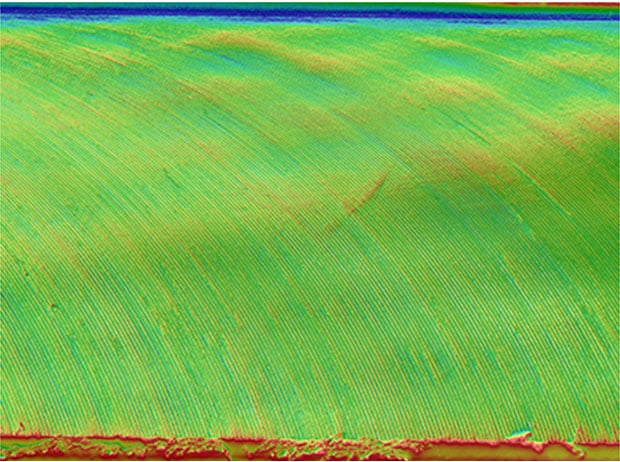

Observation of a cut surface

Optical Shadow Effect Mode allows for observation of waves on a cut surface, which is conventionally only possible by using an interferometer, in just a few seconds.

20×, ring illumination

Optical Shadow Effect Mode image

Get detailed information on our products by downloading our catalog.

View Catalog