Boosting Efficiency in Food Inspection: The Power of Automated Colony Counters

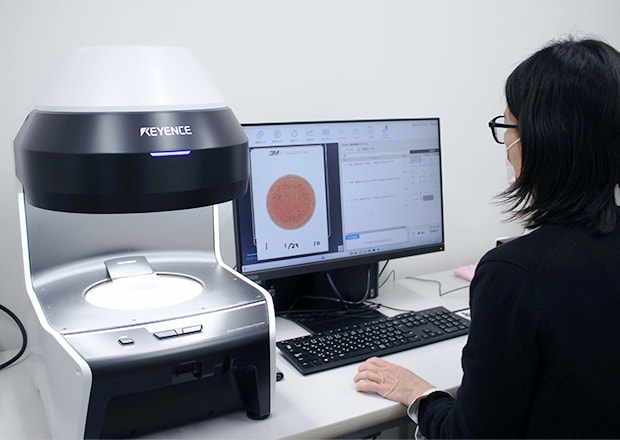

The BC-1000 Series can tell you the exact colony count in an instant.

With KEYENCE’s High Accuracy Automated Colony Counter, we were able to increase the number of specimens being tested in a limited amount of time.

Currently, We Are Also Trying to Create a Manual to Standardize Inspections Using the BC-1000 Series

Toriji Foods Co., Ltd. introduced KEYENCE’s High Accuracy Automated Colony Counter, the BC-1000 Series, to speed up the inspection of raw chicken meat for general live bacteria and coliforms. This allowed them to increase the number of specimens being tested per day, and they are also working to standardize the tests.

Koichi Sugimoto, Deputy Manager of the Quality Control Department, was deeply involved in the adaptation of BC-1000 Series, and we interviewed him to learn more about how it is being used, how it was introduced, and its appeal.

Toriji Foods Co., Ltd.

Toriji Foods Co., Ltd. was established in 1960 and is mainly involved in the processing and wholesale of chicken products. With the latest processing equipment and quick-freezing machines, Toriji Foods Co., Ltd. can meet the various needs of it's customers with limited production of diversified products. It has a wide range of customers, including companies that provide meals to hospitals and other business establishments, municipalities, school lunches, cold food plants, and major restaurant chains.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Utilizing BC-1000 Series for Testing Raw Poultry for General Live Bacteria and Coliforms

How Is BC-1000 Series Being Utilized?

We utilize it for the inspection of raw chicken, our main product. Specifically, BC-1000 Series counts the number of general live bacteria and coliforms during product inspections using Petrifilm plates and expiration date inspections.

Per specimen, 12 films are judged for the count of general live bacteria and 10 films for the count of coliforms. Five specimens are inspected per day, three days a week on Monday, Tuesday, and Wednesday.

BC-1000 Series is also equipped with high-resolution imaging which is used to examine the texture of foreign objects and take photographs to include on examination result reports.

I appreciate this feature very much because we use to take analog pictures by placing the lens of a camera against the eyepiece of a microscope.

Why Do You Concentrate Your Inspections in the First Half of the Week, on Monday, Tuesday, and Wednesday?

The main reason is that we are understaffed.

When testing, it is first necessary to cultivate the bacteria on the specimen. Therefore, it takes 48 hours for general live bacteria and 24 hours for coliforms from the time the specimen is taken to the time it is judged.

However, our company has only one inspector. Moreover, they work only on weekday mornings. Considering that the general live bacteria needs to be tested and judged two days after cultivation starts and coliforms need to be tested and judged the day after cultivation starts, cultivation can only be performed on Monday, Tuesday, and Wednesday.

Especially on Wednesdays, in addition to the day’s cultivation, the inspector had to test and judge the general live bacteria that were cultivated on Monday and the coliforms that were cultivated on Tuesday, which placed an extremely heavy burden on the inspector.

We’re here to provide you with more details.

Reach out today!

Introducing BC-1000 Series to Streamline and Standardize Inspections

How Did You Come to Introduce BC-1000 Series?

The Quality Control Department that I am a part of is protective of itself. Therefore, there is a limit to the number of staff we can allocate, and as I mentioned earlier, we have only one person in charge of inspections.

However, both internally and externally, inspection requirements are increasing year by year. Therefore, there was a sense of urgency to increase the number of inspections while keeping the same number of personnel. It was also necessary to establish a system that would be able to respond in the event that the person in charge of inspections left the company for some reason.

It was then that I received a sales call from KEYENCE for BC-1000 Series. After hearing more details and comparing it with other companies’ colony counters, we decided to install it, hoping that it would make things a little easier for our inspector.

What Were the Deciding Factors in Your Decision to Introduce the System?

There were four major reasons.

- It would allow us to increase the number of specimens efficiently.

- It would help us standardize our inspections.

- We would use the microscope function.

- We were able to lease it.

We were unsure of whether we should introduce BC-1000 Series because it is not inexpensive and there were doubts as to whether its range of capabilities was necessary for us. However, so long as our inspection team was only going to have a single person, we had high expectations that BC-1000 Series would play a significant role in improving efficiency and standardization, and ultimately, we decided to introduce it.

The fact that the lease contract offered significant advantages in terms of warranty period compared to a lump-sum purchase also encouraged us to introduce the system. This warranty gives me peace of mind in case any issues arise.

Curious about our pricing?

Click here to find out more.

Spending 2 to 3 Months After Introduction to Check the Accuracy of the Counts

After the Introduction of BC-1000 Series, Have You Compared Its Results with Those Obtained from Visual Inspections?

Yes. We compared them by checking the differences in counts from visual and BC inspections over a period of about 2 to 3 months.

As a result, we found that the count of general live bacteria was highly accurate, partly due to the fact that only colonies were counted. On the other hand, the coliform count was based on only colonies that generated associated gas, which is a difficult task even for the human eye to judge, and depending on the number of colonies, the visual count could be slightly off.

However, even this was kept within the acceptable range for the test results by registering about three patterns of judgment sensitivity and selecting the appropriate one from among them.

Discover more about this product.

Click here to book your demo.

Number of Samples Tested per Day Increased from Three to Five with the Introduction of BC-1000 Series

How Has the Introduction of BC-1000 Series Changed Your Inspections?

With visual inspection, only three specimens could be inspected per day. The introduction of BC-1000 Series allowed us to increase this to five specimens per day.

For example, if 300 colonies were generated in a 10× dilution, it used to take a long time because each colony had to be counted visually and manually, but with BC-1000 Series, the colonies on film with a large number of bacteria can be counted in an instant.

Now That You Have Used BC-1000 Series, What Are Its Most Appealing Features?

We think BC-1000 Series has three main appealing features.

- The inspection process was sped up.

- The first appealing feature is how BC-1000 Series allowed us to increase the number of specimens as I mentioned earlier. In addition to the ability to count hundreds of colonies in an instant, the continuous count table function—which allows multiple specimens to be counted consecutively and exported as a single test sheet—also leads to more efficient testing.

- No more input errors.

- In the past, after an inspection was performed, the results were manually entered on an inspection sheet and then transferred to a separate sheet called an internal inspection report. Since human input was performed twice, input errors sometimes occurred.

However, with the introduction of BC-1000 Series, inspection sheets are now filled in automatically, which has greatly reduced the number of errors. This is another advantage of BC-1000 Series. - High-resolution photos can be captured.

- I think it is also wonderful that the condition of the inspected film can be captured as a beautiful photograph that can be reviewed in case something goes wrong.

We have not yet had any problems since installing BC-1000 Series, so this feature has not yet been utilized. However, in the event of future problems such as food poisoning, discoloration, or unusual odors, it will be very helpful to have not only numeric values but also photographs of the condition at the time of the inspection, so that we have a data trail.

We’re here to provide you with more details.

Reach out today!

Aiming to Standardize Inspections with an Eye to Improving Safety and Profitability

What Is BC-1000 Series to You?

It is something that eliminates current challenges faced by our inspector.

Neither I nor the staff in charge of inspections have been professionally trained by an inspection company. Therefore, we were somewhat unsure about our current inspection techniques. We were worried about whether the counts were accurate, given our limited manpower and time.

In this respect, it was a great advantage to have BC-1000 Series to confirm that what we had done was correct because we could see how this specialized machine counted colonies and that its results were the same as those obtained with our techniques.

What Is Your Outlook for the Future?

The Quality Control Department is considering further increasing the number of specimens and, if possible, increasing the number of personnel in charge of testing.

With those goals in mind, we are currently compiling a manual for internal use on how to conduct inspections using BC-1000 Series. We hope to complete this manual by the end of this year.

After we have reached these goals, I believe we will be able to see various trends, such as differences in bacteria counts by supplier and season. By analyzing the results of this data, we can expect to improve safety and profitability, by using factors other than price to consider what we purchase.

Currently, I think we are only using about 15% of BC-1000 Series capabilities. I would like to further utilize BC-1000 Series in the future to reach the goals stated above.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us