Spectral Interference Displacement Sensor

With KEYENCE’s spectral interference displacement sensors, it’s possible to measure absolute distance with nanometer-level resolution. Sometimes referred to as spectral interferometers, these specialized sensors are used to accurately measure distance, position, and thickness in a variety of industries.

Product Lineup

Features

Ultra High Resolution 1nm

Spectral Interference Method that enables 1 nm Resolution.

Head Variations That Expand the Range of Possible Measurements

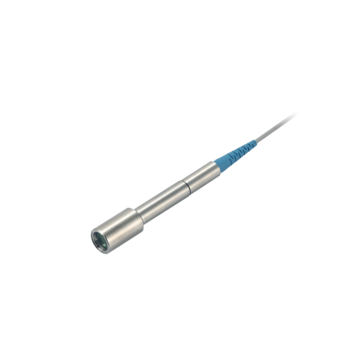

The lineup includes ultra-small, long-range, and other specialized heads to match a variety of applications.

With the adoption of the near-infrared SLD, thickness measurement for the wafer alone is possible even while BG tape is affixed. Even when there is strong pattern-based variation on the surface of the wafer, accurate in-line measurement is possible. The SI-F80R Series features an extremely small size, lightweight, and heat resistant design, which allows the head to be installed in places that can’t accommodate conventional sensors. Furthermore, the construction of the head itself provides incredibly accurate measurements, as it isn’t susceptible to heat generation nor influenced by electromagnetic noise.

In the context of metrology, spectral interferometers or spectral interference displacement sensors are used for precise measuring of various physical properties, especially in applications that involve thin film thickness determination and surface profiling. These devices emit light, which is split into a reference beam and a simple beam—the latter of which interacts with the scanned material. When the two beams recombine, they interfere, allowing the device to record an interference pattern.

Subsequent analysis of this pattern, called interferogram, allows the sensor to deduce the position of scanned materials. The same principle applies to surface profiling; spectral interference displacement sensors can measure the topography of a surface with nanometer precision—3.937 e-8 inch or 1 e-6 mm.

Spectral interferometry is highly valued in the realm of metrology, mostly due to its ability to deliver precise, rapid, and non-destructive measurements. This makes spectral interference displacement sensors vital to various industries, including semiconductor manufacturing and precision optics fabrication.

Non-Destructive

Spectral interference displacement sensors rely on the principles of spectral interferometry, which doesn’t require any contact with the sample to make measurements. This is rather important in silicon wafers, semiconductors, and hard-disk drive platter manufacturing since physical contact with the surfaces of these samples might permanently damage them. As such, spectral interferometry does not introduce any mechanical stress, deformation, or other damage to the sample—all of which is very important when measuring fragile micro-scaled structures.

High Precision and Accuracy

Many modern applications, such as wafer manufacturing, rely on nanotechnology and advanced manufacturing, which requires measurements at the very fine end of the length scale since even the smallest inaccuracies may lead to significant problems in the final product.

Given the sensitivity of interference patterns to even the slightest of changes, any adjustment, no matter how minute, will cause detectable shifts in the interferogram. This kind of sensitivity allows spectral interferometry measuring methods to offer incredibly high precision down to the nanometer level in more specialized settings.

Rapid Measurement

Spectral Interference Displacement Sensors and laser interferometers can record interferograms in fractions of a second, leading to fast measuring, and thus, fast production speeds. These fast-recording capabilities, combined with modern data processing technologies, allow for near-instantaneous surface analysis via spectral interferometry. This makes these sensors ideal for in-line metrology, where measurements are taken directly within the production line. The suitability of these sensors lies in their ability to provide precise and accurate measurements seamlessly integrated into the production process.