3D Laser Snapshot Sensor

LJ-S8000 series

Applications 3D Laser Snapshot Sensor LJ-S8000 series

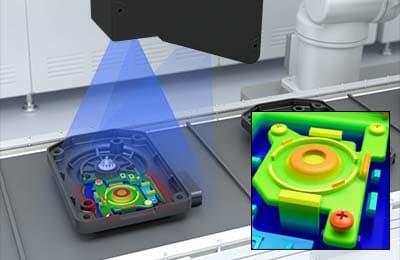

Inline 3D Inspection Examples:

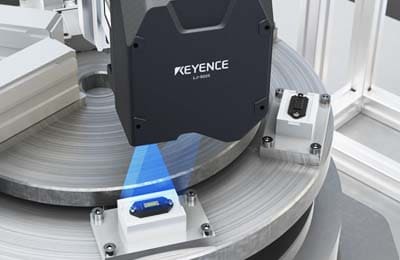

Index table

Inspections can be completed with only short, temporary target stoppage.

The LJ-S Series can be easily attached to existing equipment without any additional devices needed.

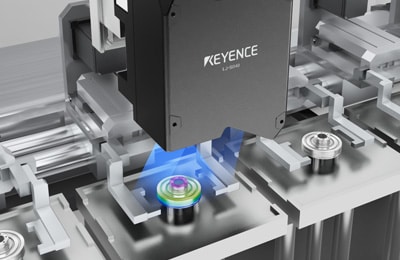

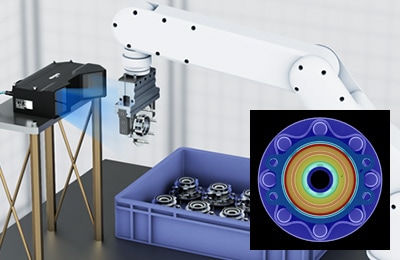

Robot-mountable

Installing the LJ-S Series on a robot allows for inspection at any angle or location without having to worry about robot vibrations or linearity due to the high inspection stability.

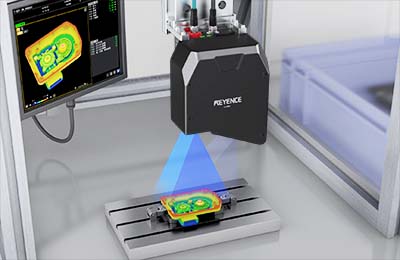

Stand-alone inspection

Automatic target position and angle detection make inspection possible when simply placing the target down by hand.

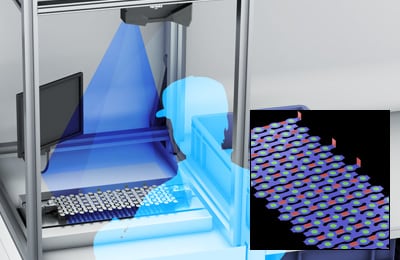

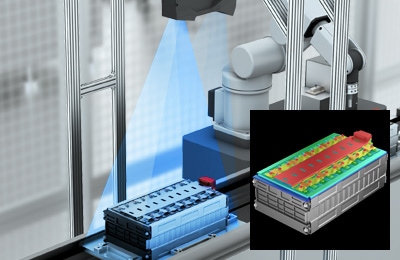

Fixed-pitch transfer feeder

Inspections can be completed with only short, temporary target stoppage, enabling easy 3D inspections on existing equipment lines.

Inspection of any target thanks to a maximum field of view of 640 × 640 mm 25.20″ × 25.20″

Significantly reduce inspection time for inline or near line inspections, especially when multiple varieties of parts are included, by utilizing 3D analysis. With the Position Adjustment function, inspection is as easy as placing the target anywhere within the measurement range, regardless of orientation.

Advantages of 3D Inspection (Automobiles/Metals)

Screw seating inspection for plastic molded products

Hub unit assembly and appearance inspection

Battery module bolt XYZ position inspection

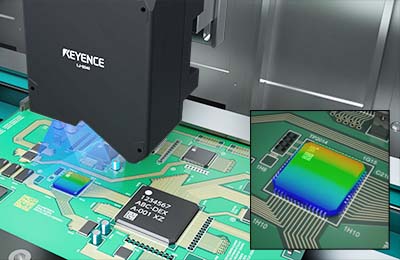

Advantages of 3D Inspection (Electrical/Electronic Devices)

Packaged component height and seating inspection

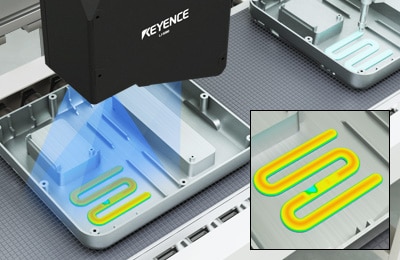

Heat dissipation material (gap filler) width, height, and volume inspection

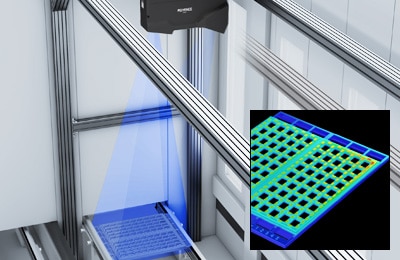

Chip transport tray warpage inspection