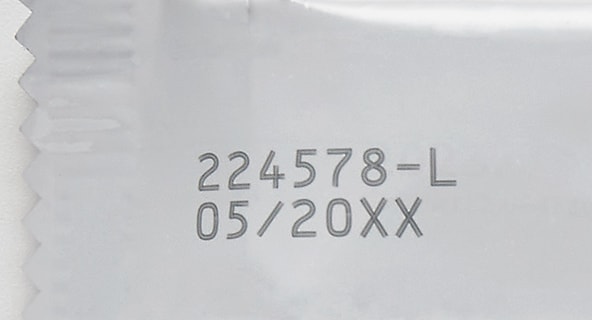

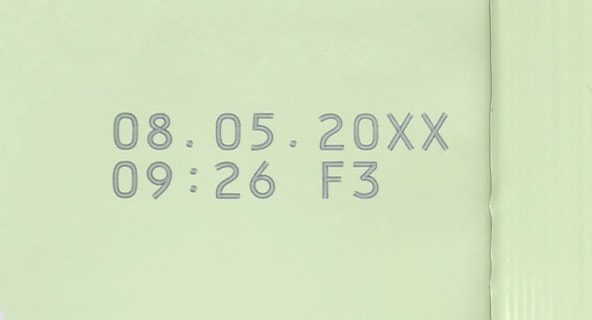

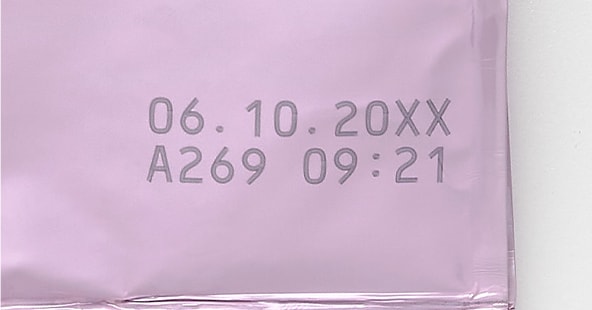

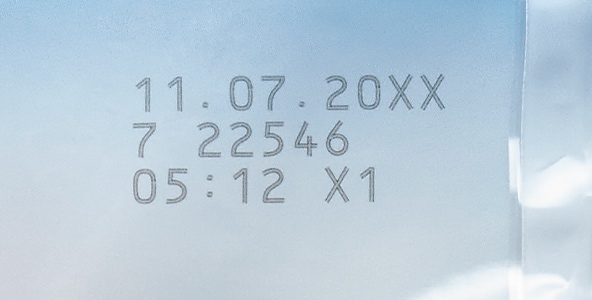

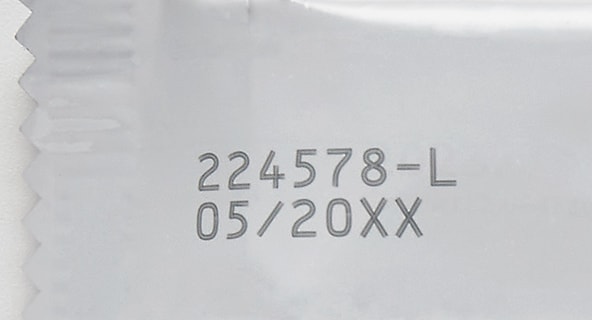

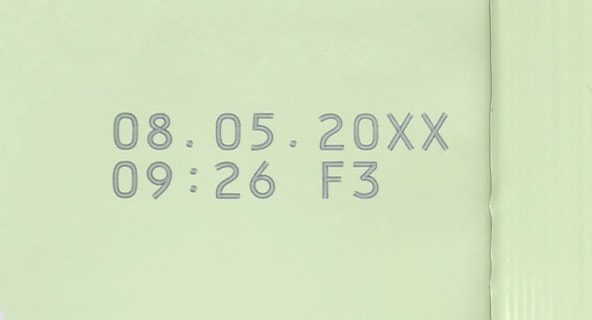

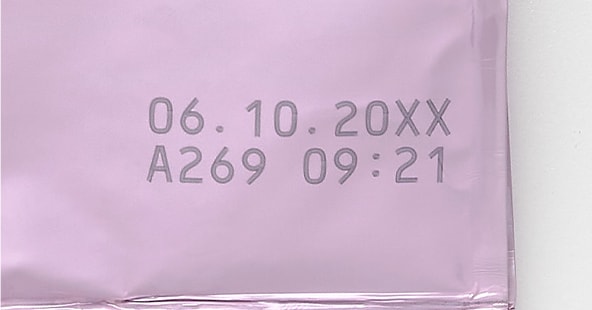

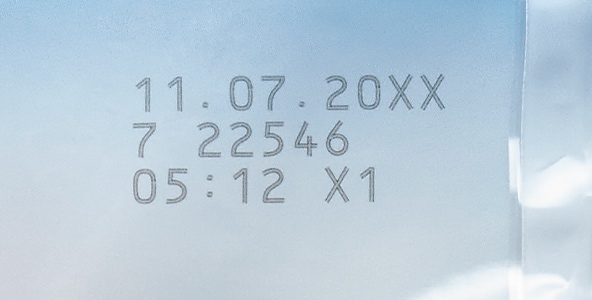

UV Laser Coding Examples for Flexible Packaging

You can also contact us at: 1-888-539-3623

What Is a UV Laser Coder?

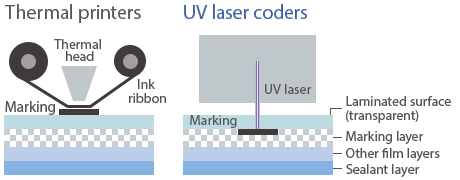

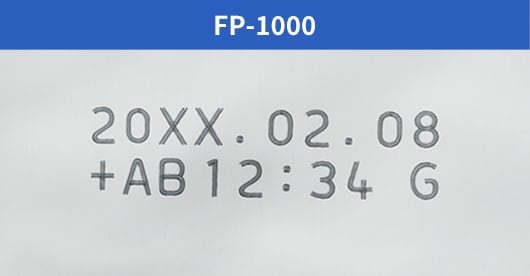

Unlike conventional thermal printers that transfer ink to the surface of the film, UV laser coders use a UV laser to mark only the marking layer of a film. This creates a permanent mark without damaging the film.

Touch panel operation has been designed to be simple to use for operators of all skill levels. Additionally, complex ribbon changes are no longer needed as the laser coder eliminates the need for consumables. These features allow the user to program and maintain the machine with limited training; reducing the risk for operator error.

Intuitive, easy-to-use interface

No need for complicated ribbon management

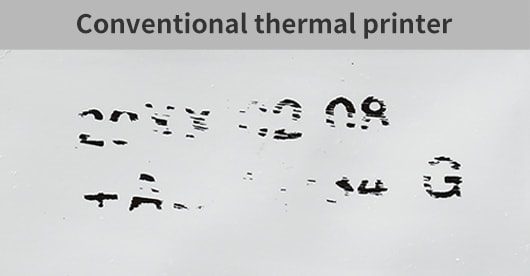

With conventional ink-based systems, there is a high risk of incomplete or faded marking. Marking by a UV laser will be permanent and flawless even when there is oil, powder, or other contaminants on the surface of the film. UV laser marked products are also immune to post-marking damage such as friction, alcohol, heat, and transportation.

Oil

Powder

Alcohol

Heat sterilization

Heads are designed to be compact for easy installation in place of existing thermal printers.

Heads can be attached to a variety of packaging machines including horizontal pillow-type packaging machines, vertical pillow-type packaging machines, bag feeding machines, and stick packaging machines.