How Businesses Benefit from Continuous Inkjet Printing and Coding on Packaging

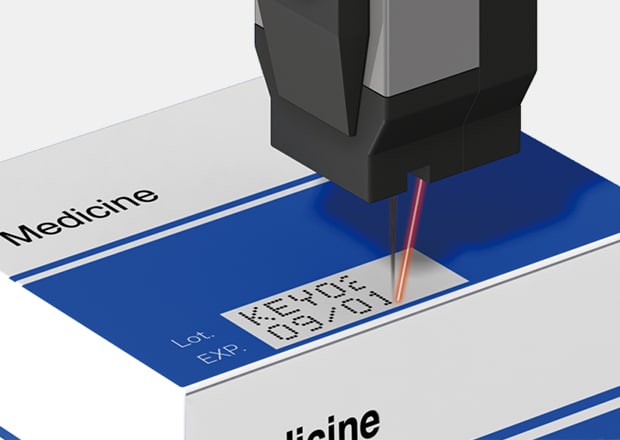

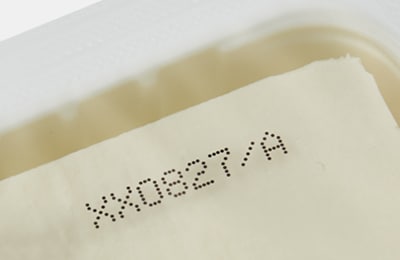

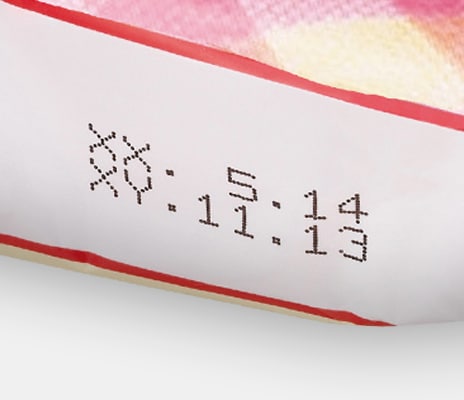

Pharmaceutical, food packaging, and beverage companies are a few examples of industries where product marking and coding are essential. Continuous inkjet printers (CIJs) help print product names and coding data, such as lot/date codes on packaging materials. Marking and coding are primarily important for product traceability and process compliance with regulatory standards.

Printing example

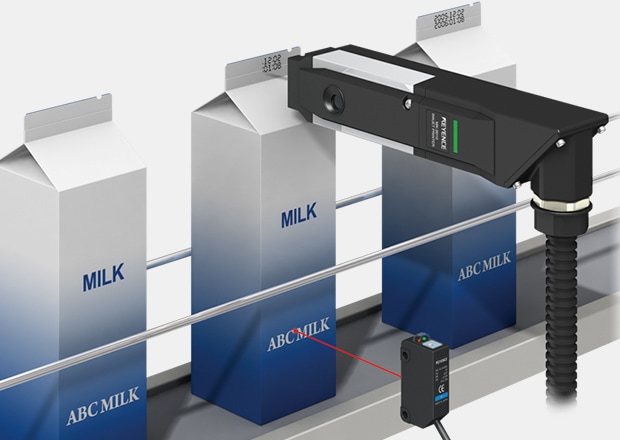

Installation example

Challenges Faced by Businesses in Traditional Coding and Marking Applications on Packaging

Traditional packaging coders and markers experience a multitude of issues relating to print quality, operational costs, and flexibility.

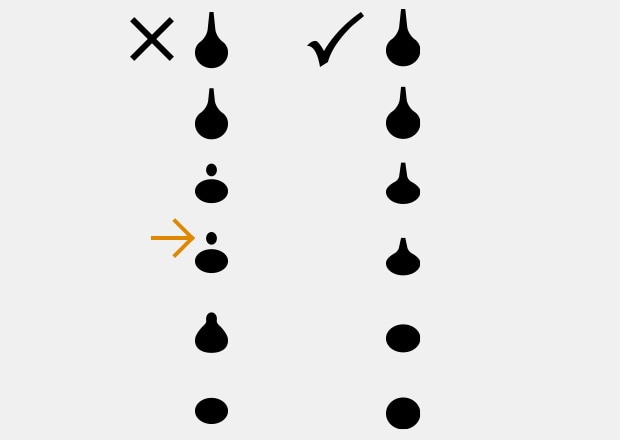

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Inconsistent Print Quality

Printed information and data should be legible, smudge-free, and resistant to fading. Cleaning solutions mixing with ink and excessive clogs greatly affect these systems, along with their adverse effect on the environment.

Less-than-optimal state of particles

Optimal particle state

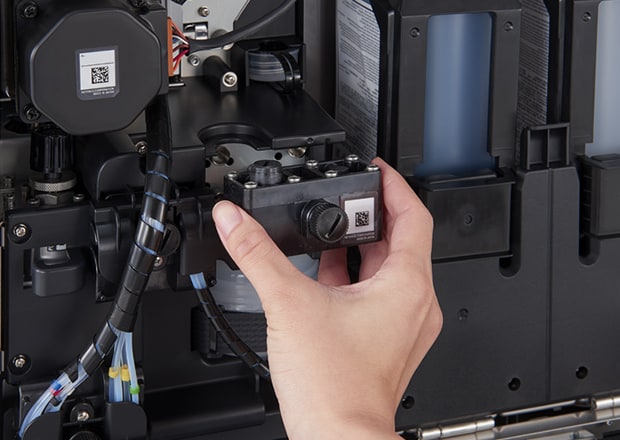

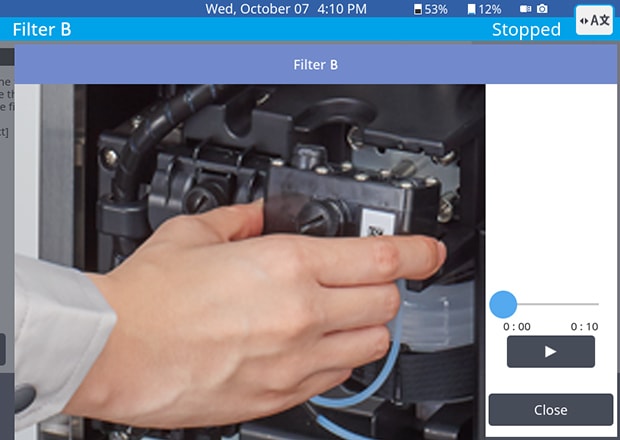

MK-G Series: tool-free, one-touch replacement

High Operating Costs

Traditional coding and marking systems require a lot of resources to maximize uptime. Increased labor needs, high consumable costs, and frequent system downtime are some of the factors contributing to their high operating costs.

Simply follow the instructional video for error-free replacement.

Access Helpful Component Replacement Instructional Videos

When replacing a component, simply read the barcode or 2D code on the component to watch a helpful instructional video. These easy-to-follow videos make replacement simple even for beginners.

Limited Flexibility

The needs of retailer customers are constantly changing due to changes in consumer tastes and preferences. These changes require packaging coders and printers that can adapt to different packaging materials and high-speed production lines, areas where many traditional systems struggle.

Pouches

Packaging film

Cartons

Glass bottles

Plastic bottles

How Do the MK-G Series Packaging Coders Address the Unique Requirements of Date Code Printing and Lot Coding in the Packaging Industry?

The MK-G Series is one of KEYENCE's industrial inkjet printers, which addresses many unique requirements and current issues with conventional CIJ coders used on today's packaging lines. It brings benefits such as cost efficiency and high-speed printing. They are also durable, reliable, and require minimal maintenance, making them a cost-effective option for businesses.

Ease of Use

The many built-in features and functions in the MK-G Series make the printer accessible to everyone. It can be operated without specialized skill or knowledge, freeing up technicians to focus on more complex tasks.

The MK-G Series features a SMART Dock, a unit that automatically cleans all major components of the printing head. Unlike traditional solutions that require manual cleaning of washable parts, the MK-G Series requires only using the on-screen instructions to activate the SMART Dock function.

The unit can also diagnose any fault with the printhead and automatically resolve them. The self-diagnose function is especially important today due to skilled labor shortages.

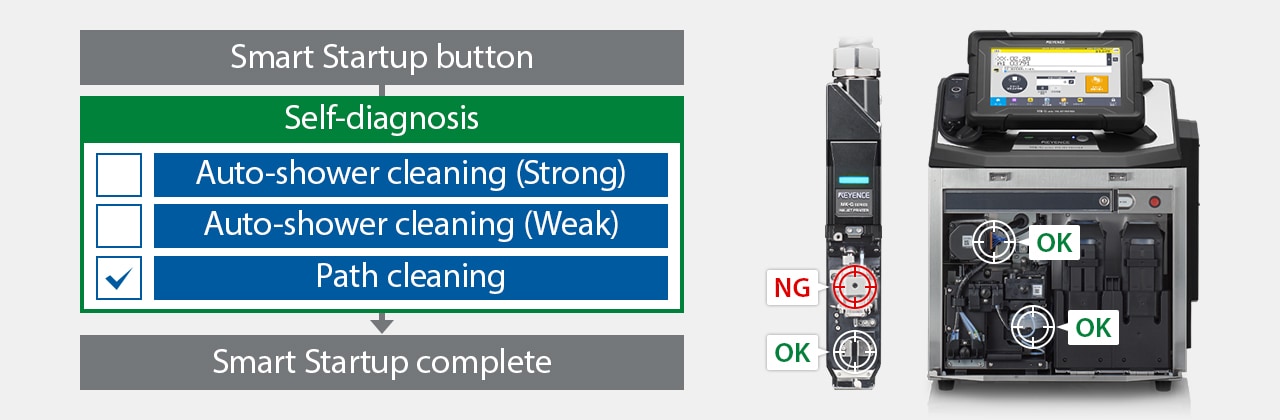

Self-Diagnosis Followed by Automatic Cleaning When Necessary

INDUSTRY FIRST Smart Startup

To start the MK-G Series, simply press the Smart Startup button. The printer will automatically obtain the device status and select the necessary cleaning method. Cleaning is performed only when required and the minimum amount of solvent is used, significantly reducing running costs.

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

High-Speed Printing

Process disruptions are affecting various supply chains, making it crucial for production lines to operate quickly and utilize resources wisely. The MK-G Series industrial prints at high speeds without compromising quality.

Durability and Reliability

The KEYENCE MK-G Series is designed for durability and resilience in various environmental conditions. Its integrated, cost-effective maintenance features include a self-diagnosis and troubleshooting module, automatic cleaning, and efficient utilization of consumables.

An IP55 rating for the head and controller means waterproof and dustproof protection, along with drop protection, making the unit usable even in extreme production environments.

The MK-G Series is rated IP55, making it both waterproof and dustproof.

Both the head and the console comply with MIL Standard drop evaluation requirements.

Traceability and Regulatory Compliance

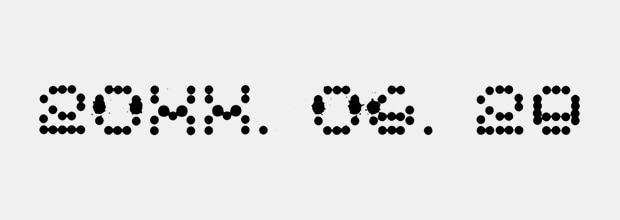

An industrial inkjet printer must mark and code quality prints and ensure that coded data or product information marks are fade-resistant. Lasting print quality ensures readability, which is a requirement when tracing recalled products and for regulatory compliance.

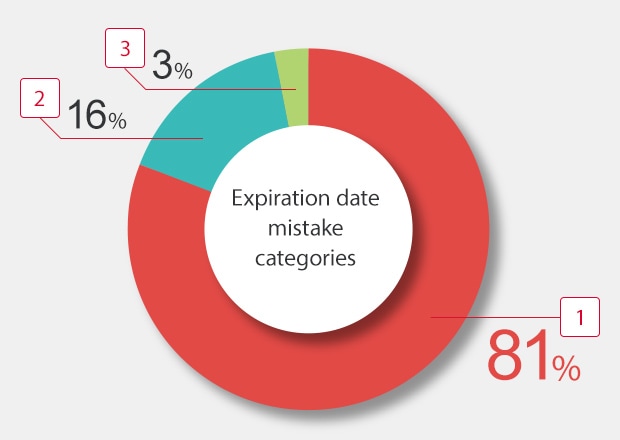

Among all the errors caused by expiration date mistakes, 81% were caused by the date being displayed incorrectly. In another 16% of the cases, printed text was missing in whole or in part.

-

1Incorrect date printed

-

2Missing printed text

-

3Other

Adaptability

Whether printing on plastic, glass, metal, paper, or cardboard, the MK-G Series can be adjusted to handle prints on various packaging materials. Printing speed and font size can also be customized to meet specific requirements.

Metal component

Plastic containers

Plastic

Packing film

KEYENCE Advantages

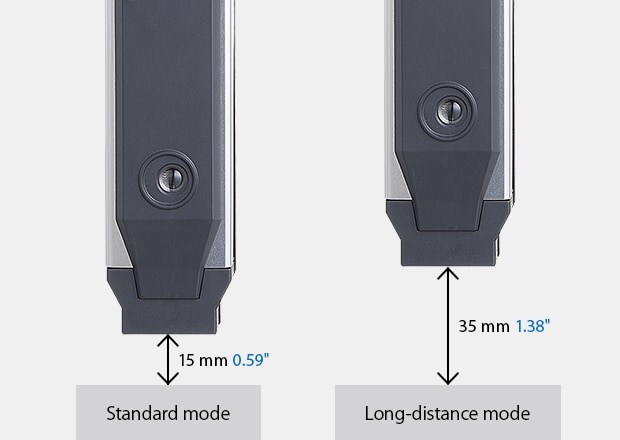

Long-distance mode

Printing can be performed with the print head located up to 35 mm 1.38″ away from the target. This makes it possible to perform stable marking that isn’t affected by variations in the thickness of printing targets and reduces the risk of print head collision.

The Versatility of KEYENCE MK-G Series in Marking Various Packaging Materials

Every industry has different packaging material requirements. Fortunately, the MK-G Series packaging coders can print on cartons, bottle labels, heat-sealed packages, pipes, cans, glass containers, cardboard boxes, and many other packaging surfaces.

To ensure proper adhesion, the printer supports a wide range of inks and solvents to choose from depending on the packaging material. Using the right ink and solvent ensures that printed information and data are clear, legible, and consistent.

There's an option for the standard fast-drying MK-10 Series black ink, which is ideal for clean black printing. In printing and packaging arrangements where black ink won't be clear, there are other highly adhesive inks in different colors.

When printing on curved, flat, and irregular surfaces, the LED pointer feature helps indicate the print location, making it easy to align the print head to the exact print position.

Also, the head direction switching makes for a head cable that can be rotated 90 degrees, eliminating the inconvenience of cable routing. The 90-degree rotation feature also makes it easy for the printer to fit into a wide variety of lines.

Whether as a CIJ for the food and beverage industry or for businesses in other industries, the MK-G Series industrial printer has all the required features.

Packaging Continuous Inkjet Coders Redefining Precision in Date and Lot Coding

The MK-G Series enhances the printing process for quality control, regulatory compliance, and traceability with precision features. KEYENCE MK-G Series is a suitable option for beverage and food production lines and an ideal CIJ for the pharmaceutical and consumer products industry.

For more information on how to get started with KEYENCE MK-G Series CIJ, contact us today.

![Packaging Technology Introduction [Packaging Machine Edition]](/img/asset/AS_82098_L.jpg)