Factors to Consider When Choosing Between Industrial Continuous Inkjet Printing vs. Laser Coding

Printing/coding on packaging materials in industrial applications goes beyond identification. It plays an essential role in product safety, brand promotion, regulatory compliance, product documentation, and many more.

Continuous inkjet printers (CIJs) and laser coders are two popular printing and coding solutions for product packages. But which option should you choose between inkjet printing vs. laser coding?

Continuous inkjet printers

Laser coders

Understanding Industrial Continuous Inkjet vs. Laser Coding

Understanding the two primary equipment systems for putting codes on packages will assist manufacturers in choosing the best option for their operations or an ideal solution for specific printing operations.

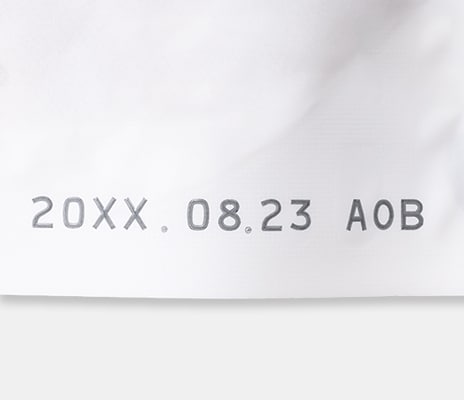

Laser coding employs advanced laser technology to form permanent markings on packaging materials. As the name suggests, the technology uses a laser beam focused on the packaging surface to create high-resolution codes, text, or other essential print information. Coded information is legible and durable. Laser coding is also an environmentally friendly marking technique that does not involve the use of inks or other harmful chemicals.

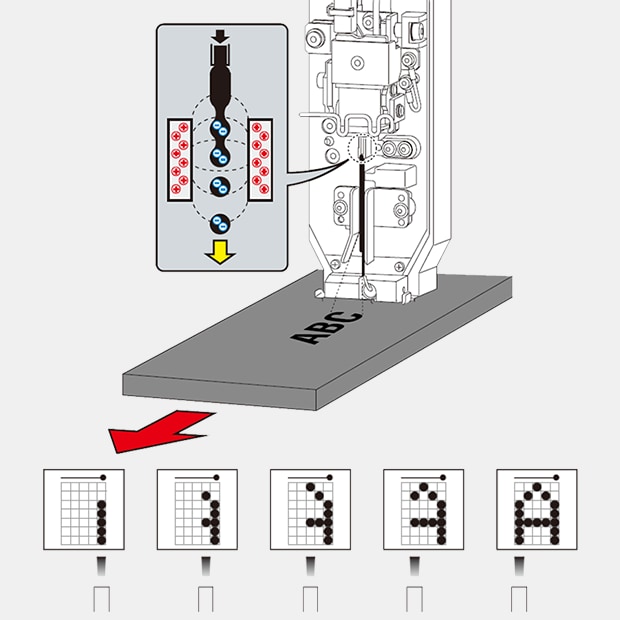

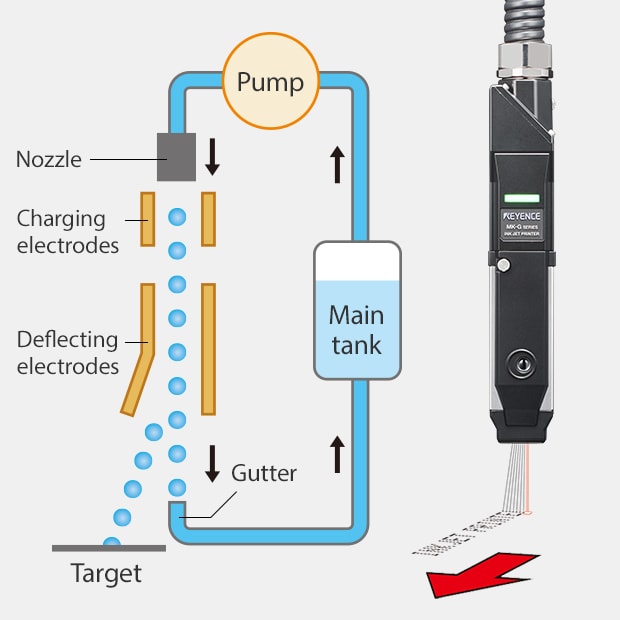

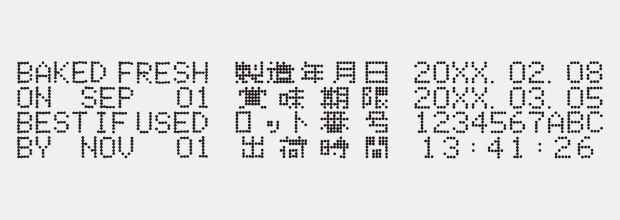

Continuous inkjet printers use a non-contact method to create small droplets of ink that are then electrostatically charged and directed toward the target material. This creates a continuous stream of ink droplets that can be precisely controlled to form characters, codes, or logos on various surfaces. The resulting codes are completed without any flaws or smudging, making it ideal for high-speed production lines.

One of the major advantages of continuous inkjet printers is their ability to print on curved or uneven surfaces. This makes them highly versatile and suitable for a variety of industries, such as food and beverage, pharmaceutical, cosmetics, and more. Additionally, these printers can handle different types of inks and color options.

Printing principle

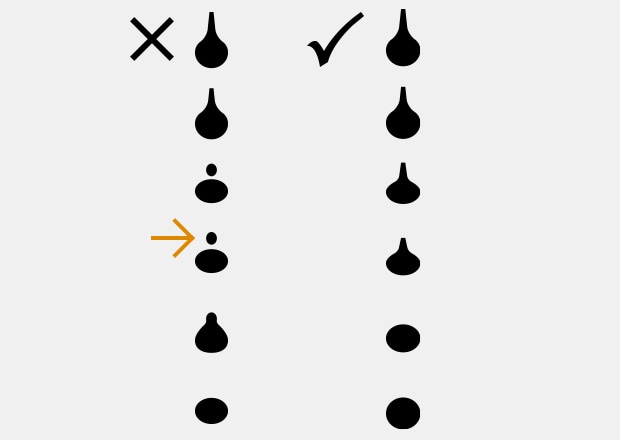

Internal path and circulation principle of ink

Cost and Operation Considerations

Operational considerations in terms of costs are a good place to start the inkjet vs laser coding evaluation. Understanding the requirements for purchasing and installing either of the two solutions in a production line, as well as the ongoing costs associated with maintaining the system once operational, is essential.

Initial Investment and Operating Costs

CIJs generally have lower entry costs compared to laser coder systems. CIJ printer options are available in low-speed, light-duty, and ultra-fast systems. The high-end options are ideal for meeting the highest production line speeds. Because they are more affordable, especially relatively small businesses with budget constraints will find CIJs accessible.

To ensure maximum product uptime and optimal performance, continuous inkjet printers require regular maintenance. Operating expenses include ink purchases and parts replacements, which can be especially high in conventional older systems. The printhead, for example, must be periodically cleaned and replaced due to its susceptibility to clogging.

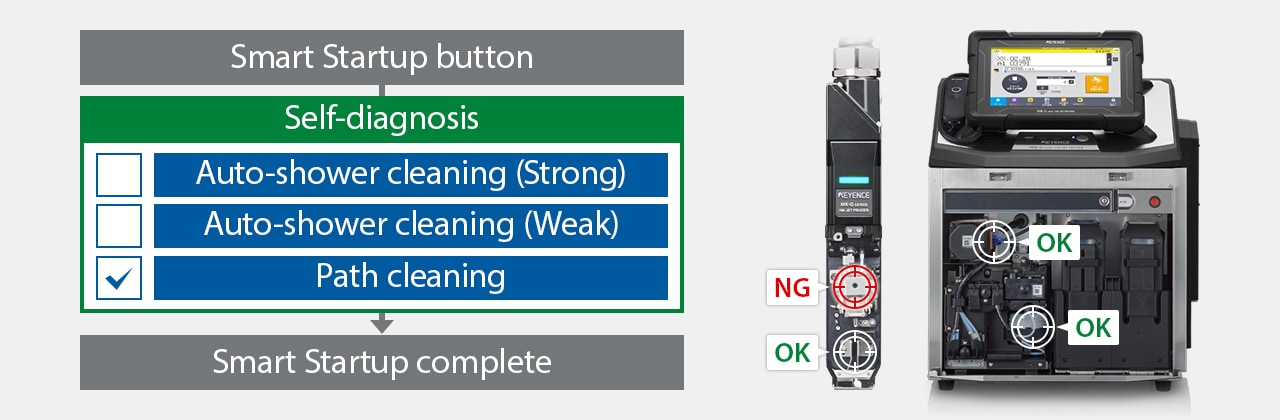

KEYENCE offers new continuous industrial inkjet printers that provide automatic cleaning, self-troubleshooting options, and many other features that reduce operational costs.

Alternatively, laser coding requires relatively high initial equipment costs but offers cost savings through low maintenance requirements. For example, laser coders do not require consumable inks to print. Once installed, a laser only needs occasional calibration and a conducive environment to run efficiently.

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

Longevity and Durability of Industrial Inkjet Printers vs. Laser Coders

First, industrial inkjet printer and laser coder technologies have significantly improved over the years. More recent systems are durable when appropriately used for suitable applications.

Issues usually arise with inkjet printers if they stay idle for a long time. When used infrequently, CIJ printer nozzles can clog and stop working altogether, requiring replacement. Because they don't utilize ink systems, laser coders can be left alone for some time and resume operations.

Additionally, when assessing durability, it's crucial to consider the specific printer in question. Factors such as enclosure design and overall build quality, along with the longevity of the printer's components, should be taken into account. Keep these considerations in mind while evaluating the durability of industrial inkjet printers vs laser coders.

With their solid build design and regular printing, continuous inkjet printers may be a durable and cost-effective solution for certain needs. On the other hand, laser coders can relatively complete more print jobs before needing maintenance or replacement.

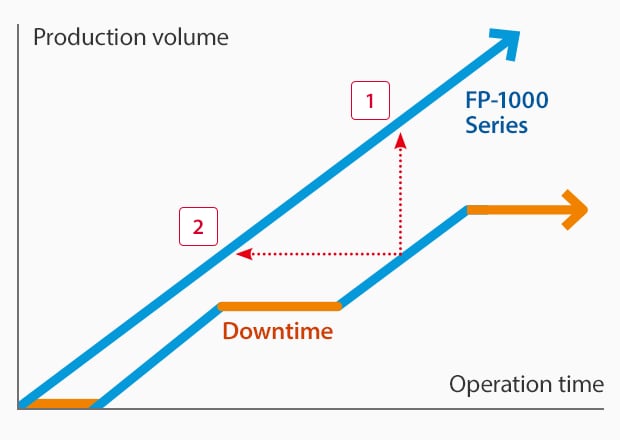

-

1More production in the same amount of operation time

-

2Less operation time for the same production volume

Print Quality and Capabilities

In addition to purchase and operational costs, print quality and capabilities are worth considering. Print performance is crucial for industries with strict regulatory compliance. Also, the capabilities in terms of speed, material handling, and resolution can make or mar production efforts.

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Less-than-optimal state of particles

Optimal particle state

Print Resolution and Versatility in Marking Different Substrates

Laser technology shines with its ability to produce sharp prints in high resolution. Laser coders can deliver fine details and crisp lines for a more visually appealing result on different surfaces, including plastic, metals, and glass.

Character size: 3 × 2 mm 0.12" × 0.08"

No. of characters: 10 characters

Marking pitch: 150 mm 5.91" spacing

| Line speed | Marking volume | |

|---|---|---|

|

UV laser coder

|

Line speed

150 meters 492.1'/minute

|

Marking volume

1000 items/minute

|

*Results will vary according to marking conditions and material.

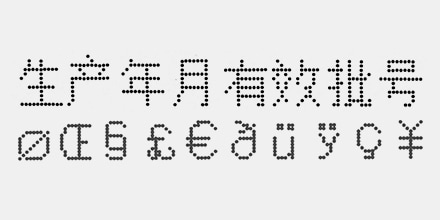

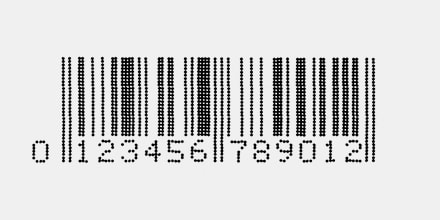

In contrast, continuous inkjet printing provides good clarity in the printing of barcodes, alphanumeric characters, and simple graphics. While it may not offer the same level of detail as laser coding, CIJ printing is also legible and durable.

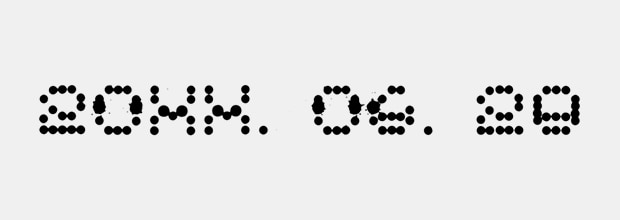

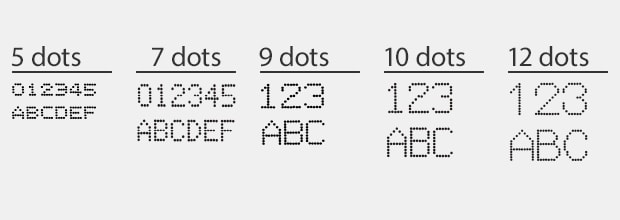

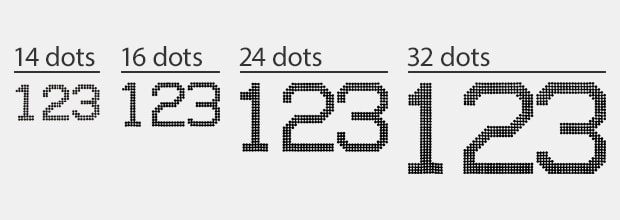

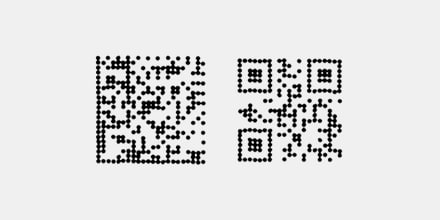

5-12 dots

14-32 dots

Four-line printing

Logotypes

Unique-character languages

Barcode

2D codes

Performance of Continuous Inkjet vs. Laser Coding Solutions in High-Speed Production Environments

Continuous inkjet printers are renowned for their high-speed printing and reliability capabilities, making them well-suited for fast-paced production lines.

Heat-sealed package

Form-filled package

Plastic bottle

Carton

While laser coders may not match the speed of continuous inkjet models, their exceptional precision makes them perfect for intricate designs where speed is not the primary focus.

Granule package

Retort food pouch

Toothpaste tube

Alcohol container

Optimizing Manufacturing Efficiency with Continuous Inkjet and Laser Date Coding Solutions

There is no single best solution for industrial coding and printing needs. The choice of print technology depends on factors such as installation and operational costs, print quality, material support, and speed.

Selecting an ideal printing and coding solution will help optimize manufacturing efficiency.

KEYENCE provides both continuous inkjet printers and UV laser coders to meet the diverse needs of modern manufacturers. All solutions come equipped with standard and advanced features that make lot or date coding information clear and long-lasting. Their versatility also makes them suitable for different industrial applications.

For expert assistance on inkjet versus laser coding products or to learn more about our solutions, contact us today.

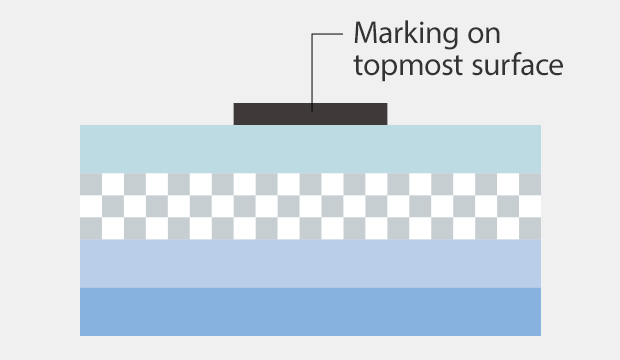

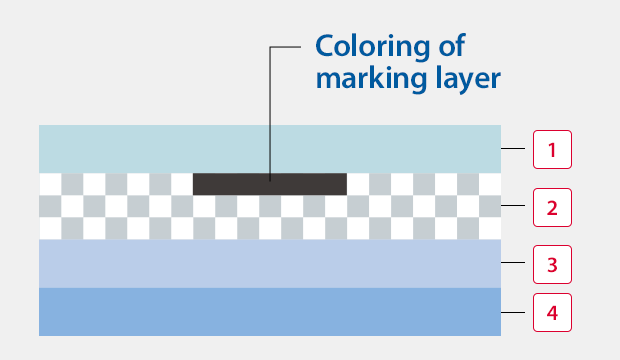

Conventional ink-based systems

UV laser coder

-

1Laminated surface (transparent)

-

2Marking layer

-

3Other film layers

-

4Sealant layer

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)