Continuous Inkjet Printers / Case Coder

Coding in the Wire and Cable Industry

To meet safety regulations, wires and cables need clear and precise coding. KEYENCE's continuous inkjet printers (CIJs) deliver clear, high-quality codes on various materials with minimal user input. With dot quality measured and adjusted 10 times/sec plus automatic maintenance and troubleshooting, you’ll reduce the need for user input, save time, and eliminate rework and scrap.

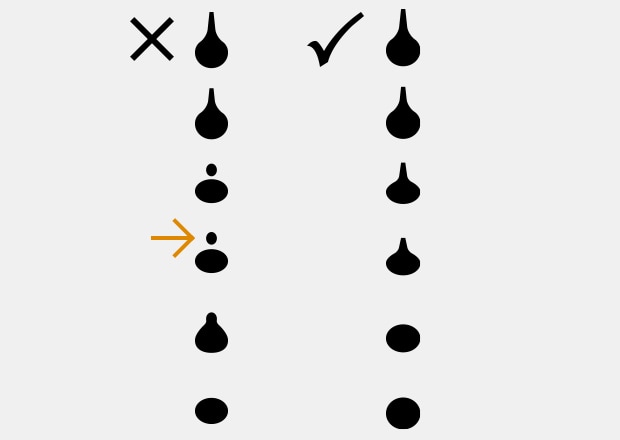

Particle state

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Less-than-optimal state of particles

Optimal particle state

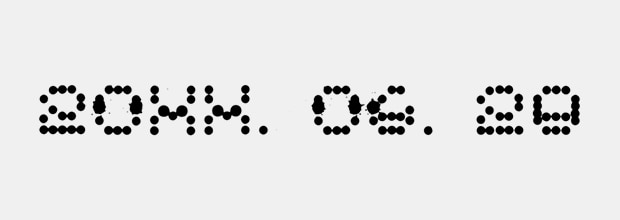

Date Coding and Marking on Wire and Cable

Installation example

Extrusion Molding Pipes

Date coding and marking on extrusion molding pipes are highly versatile, working effectively with various pipe sizes and materials, such as PVC. These clear, quality marks adhere strongly to the pipes, enabling accurate tracking through the supply chain.

Cable Marking

High-resolution printing allows for easy labeling of cable type, length, voltage rating, and more on fiber optic, copper, and other cable materials. This ensures the markings adhere to electrical codes and regulatory requirements to maintain compliance.

Printing example

Wire Coding

Non-contact marking on wires is ideal for thinner, more fragile types, ensuring durable, long-lasting marks that withstand typical wear and tear. This enhances traceability in electrical and similar systems, providing reliable identification and compliance.

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking for the Wire and Cable Industry

Strict Industry Regulations and Requirements

Strict regulations for coding in the wire and cable industry can be challenging, especially with rising standards for tiny components. KEYENCE CIJs meet these demands by ensuring easy traceability and providing inspection capabilities in tandem with marking.

Balance Different Packaging Types

Balancing different packaging types, often made of sensitive materials that traditional marking methods can easily damage, can be difficult. KEYENCE CIJs adapt to various packaging types and surfaces, ensuring clear codes with great adhesion, minimal maintenance, and increased uptime.

Installation example

Speed of Production

Keeping up with production speed is a major challenge, as systems must print quickly without errors. KEYENCE CIJs handle this by achieving extremely high print speeds over 365.8 m 1,200 ft/min, with automatic maintenance and dot quality adjusted 10 times per second for high-quality print while maintaining high quality and consistency.

Curious about our pricing?

Click here to find out more.

CIJ for Wire and Cable

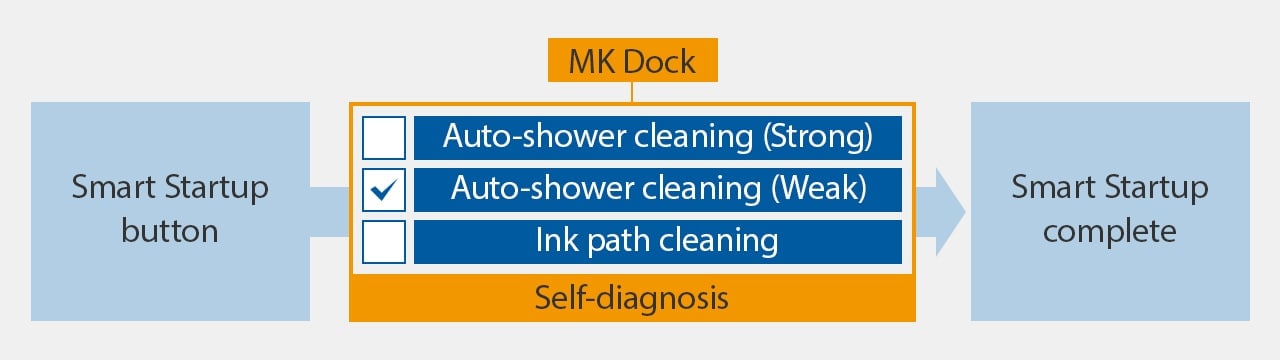

MK-G Series

Featuring self-diagnostic and optimal cleaning capabilities, this continuous inkjet printer handles wire date and lot coding with ease. The automatic maintenance and optional assist camera benefit production timelines while consistently working to reduce coding entry mistakes.

Get detailed information on our products by downloading our catalog.

View Catalog

FAQs about Date Coding in the Wire and Cable Industry

What Advantages Do KEYENCE CIJ Coders Offer in Terms of Product Traceability and Quality Assurance?

KEYENCE CIJ coders ensure reliable, high-quality, and accurate codes with high marking permanence and minimal user error. The non-contact printing, ease of use, and durability, reduce running costs and exposure to printer chemicals.

What Are the Primary Applications of Date Coding and Marking in Wire, Cable, Tube, and Pipe Manufacturing?

Date coding and marking in wire, cable, tube, and pipe manufacturing are used for traceability, quality control, and regulatory compliance. It also simplifies inventory management and branding, ensuring products meet all required standards.

How Can KEYENCE's Continuous Inkjet Printer Enhance Traceability and Quality Control Throughout the Wire and Cable Industry?

Our industrial inkjet printers monitor breakpoints ten times per second for high-quality prints. In the event of a power outage, a built-in backup power unit allows for print to be completed and then an emergency shut down is completed. This eliminates scrap and rework for interrupted wires/cables and saves the printer from clogs and damage from these improper shutdowns.

How Does the MK-G Series Ensure Consistent and High Print Quality on Wire and Cable Coding Despite the Wide Range of Materials Used for Various Wires, Cables, Pipes, and Tubes?

The MK-G Series ensures consistent and high print quality by maintaining high throughput and marking speed, plus active real-time breakpoint calibration. Its ease of maintenance, compact size, and minimal human interaction reduce user error and make it easy to integrate into production lines.

How Does the MK-G Series Simplify Troubleshooting for Coding on Wire and Cable Manufacturers and Reduce the Frequency of Production Interruptions and Scrapped Parts?

Self-troubleshooting capabilities and step-by-step maintenance guides, regardless of skill level, reduce production interruptions and scrapped parts. Features like one-touch nozzle replacement and backup power modules ensure seamless operations, even in the event of power loss.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.