Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Coding on Piping and Extruded Materials

Lot and date coding is essential in tracking production batches and ensuring material traceability. Coding on piping and extruded materials must remain 100% clean and readable to accurately trace defective products.

KEYENCE CIJs for industrial manufacturing offers fast, consistent, unique codes on a wide range of materials, including PVC, ABS, copper, and many more.

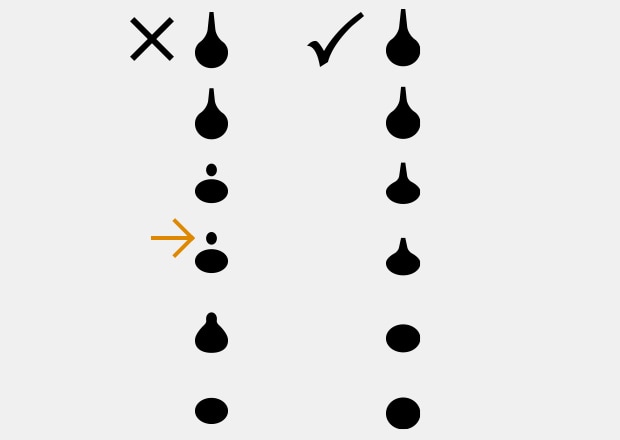

Particle state

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Less-than-optimal state of particles

Optimal particle state

Lot/Date Coding and Marking on Piping and Extruded Parts

Installation example

Pipes

The KEYENCE MK-G Series of continuous inkjet printers ensures quick, high-quality pipe production. Easy cleaning and maintenance prevent stoppages, and physical/environmental durability ensure smooth operation on any production lines.

Extruded Parts

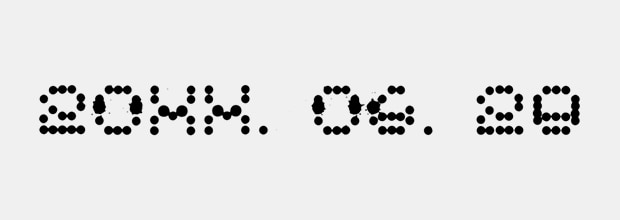

Adhesion and print quality are critical for extruded parts. The MK-G Series monitors break point and dot condition 10 times per second, ensuring high-quality codes and eliminating scrap.

Printing example

Extruded Tubing

Coding and marking extruded tubing is a continuous process. The MK-G Series is built with automatic maintenance features that reduce stoppages, downtime, and costs.

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Extruded Tubing and Piping

Harsh Environments

Harsh production environments can lead to difficulties with frequent cleaning and downtime caused by dust and debris. The MK-G Series has an IP55 rating for not only the controller but also more importantly the print head, providing unmatched protection against both water and dust ingress.

Maintenance

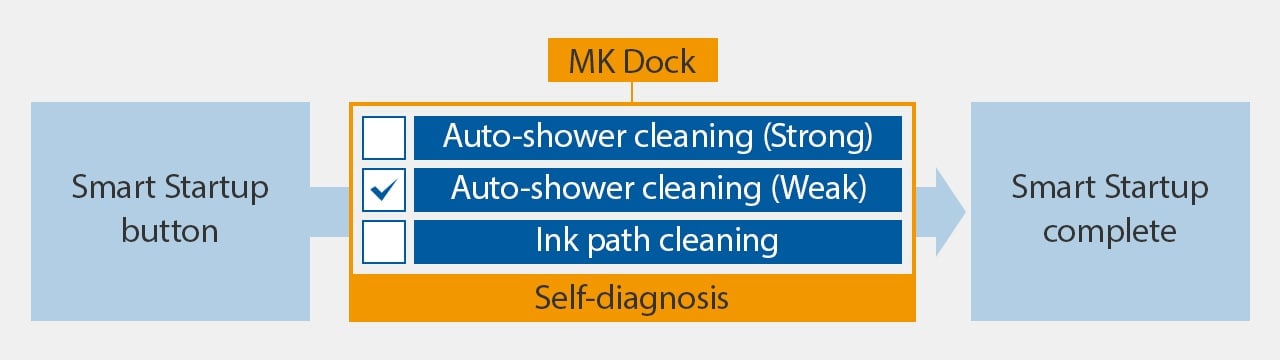

Equipment for coding and marking pipes require specialized knowledge and training to operate. The MK-G Series can self-troubleshoot and perform maintenance and cleaning, reducing the need for a skilled technician or service contract.

Compliance and Traceability

Printing errors or smudges can lead to incorrect information and traceability issues. Our MK-G Series provide clear, reliable printing on extruded tubing and piping.

Curious about our pricing?

Click here to find out more.

CIJ for Piping and Extruded Parts

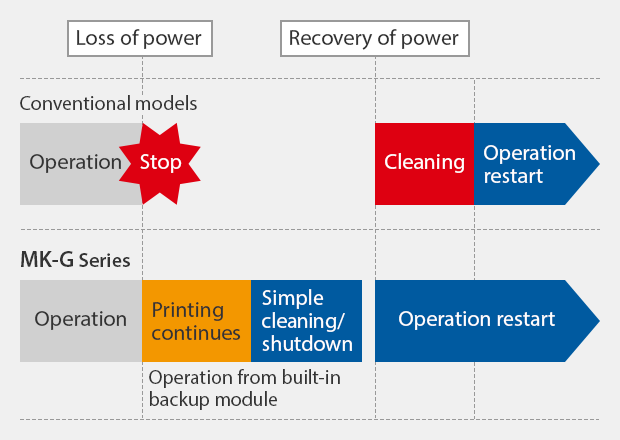

Piping and extruded parts require precise marking or coding to ensure traceability. MK-G Series industrial inkjet printers ensure this with a user-friendly interface, self-diagnostics on startup to determine if cleaning is necessary, and automatic troubleshooting. Built-in backup power helps the CIJ complete printing (eliminates scrap) and increases uptime in the event of a brief power interruption. The one-touch nozzle replacement feature enables rapid printing recovery without tools, minimizing downtime, and it also connects to the web so users can monitor its status from a PC or smartphone.

One-touch nozzle replacement

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Date Coding in the Piping and Extruded Materials Industry

How Does Lot/Date Coding on Piping and Extruded Materials Enhance Quality Control and Traceability in Manufacturing Processes?

Lot/date coding is key for quality and product tracking. The MK-G Series can easily be linked to inspection equipment to quickly trace/identify issues to specific lots.

What Are the Advantages of Using KEYENCE MK-G Series CIJs for Coding and Marking Extrusions?

Advantages include reliable, high-quality prints and withstanding harsh environments. They also perform automatic cleaning and self-diagnostics with minimal maintenance, reducing downtime and the need for skilled workers.

What Factors Should Be Considered When Selecting a Coding and Marking Solution for Extruded Tubing and Pipes?

Marking quality, consistency, and ease of cleaning/maintenance are factors to consider before choosing a solution for lot/date coding on piping and extruded materials.

What Types of Extruded Parts, Such As Piping, Can Be Marked or Coded Using CIJ?

KEYENCE CIJs can print on a wide range of materials, including piping, tubes, cables, and wires.

How Can KEYENCE CIJ Solutions Benefit Production Efficiency for Coding and Marking Extruded Tubing and Piping?

Benefits include ease of use, self-troubleshooting capabilities, and robust build for harsh conditions make production efficient with seamless integration into production lines.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper