Continuous Inkjet Printers / Case Coder

Coding on Electrical Components & Electronic Parts

From microchips to circuit boards, accurate labeling of electronic components is essential. Traditional methods like stamping or labeling are time-consuming and prone to errors.

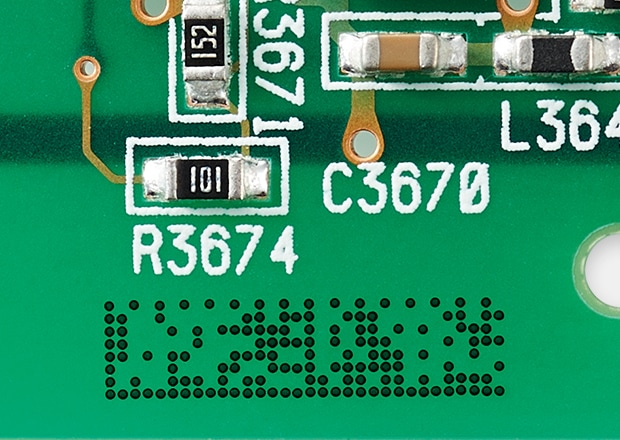

Continuous inkjet printers feature a micro nozzle for accurate small-size printing, ensuring clear coding. The KEYENCE CIJ printer monitors break points and dot conditions 10 times per second.

Lot Coding and Marking on Electrical Components & Electronics

Substrates and Wafers

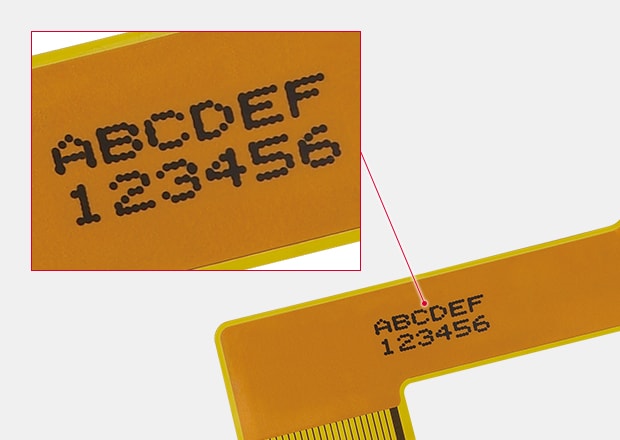

Identification of substrates and wafers requires lot codes/serial numbers. The challenge is printing on limited space without damaging flexible PCBs and wafers. CIJ printers can mark high-quality codes in different sizes and on various materials, ensuring compatibility.

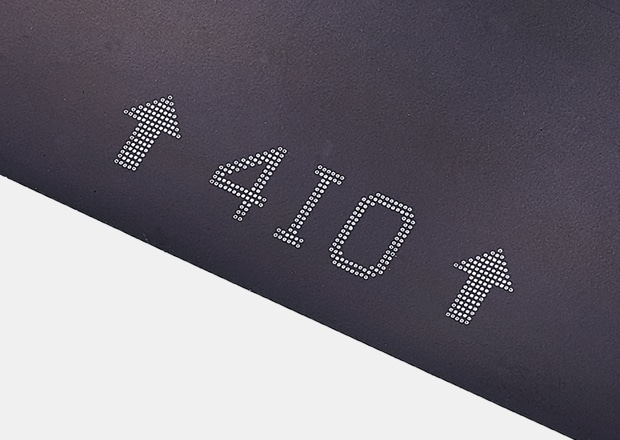

Batteries and Other Curved Surfaces

A major challenge in the electrical and electronics industry is printing on curved or uneven surfaces, like cylindrical batteries. KEYENCE CIJ printers are non-contact printers, ensuring accurate and legible coding on electrical components and electronic parts even on difficult products.

Inspection Machines

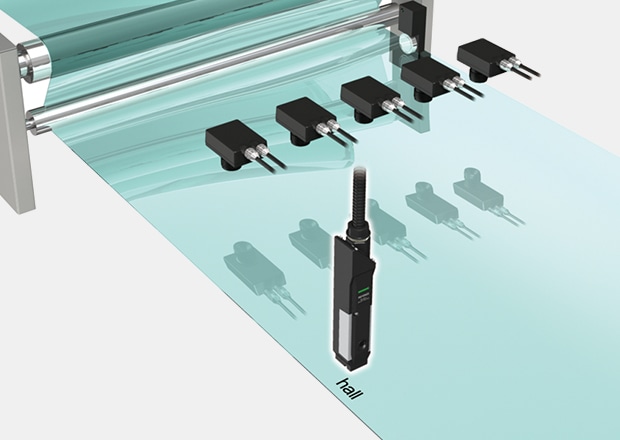

Inspection machines carry out camera-based inspections for defects. KEYENCE CIJ printers work with inspection machines to print defect-related data captured by cameras or inspection systems with a micro nozzle unit for precise defect markers.

Printing example

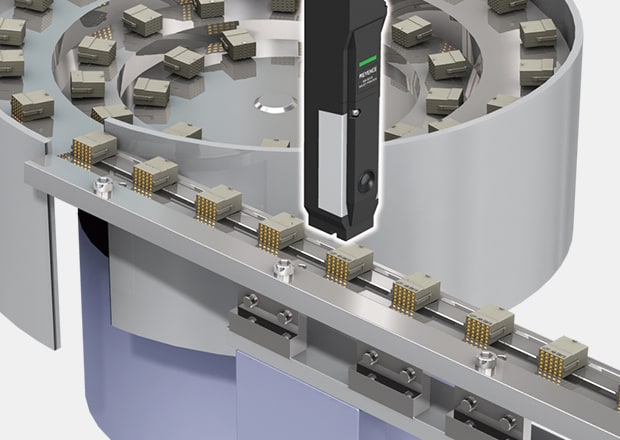

Installation example

Connectors and Other Electronic Components

Industrial inkjet printers ensure traceability and quality control by marking lot codes, batch numbers, and essential data at high speed, maintaining quality and reducing rework and scrap.

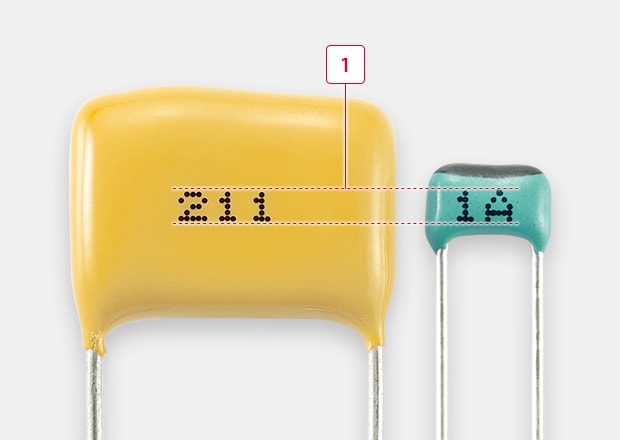

Printing example

Installation example

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Small Electrical Components & Electronics Parts

Printing of extremely small characters

The MK-G Series includes a extremely small-diameter 40 μm 1.57 Mil nozzle for printing small characters and 2D codes.

* MK-G1100 small character type

Miniaturization of Electronic Devices and Components

Coding on electrical components & electronic parts is challenging due to limited surface area. KEYENCE CIJs solve this with their MK-G1100 micro nozzle, printing tiny 2D barcodes on miniature components for accurate and visible information.

-

1Character height 0.6 mm 0.02"

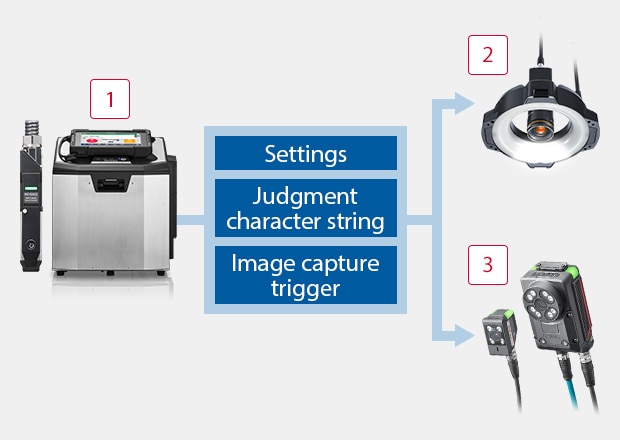

Easily link to a print inspection device with a just a LAN cable

High-Quality Standards

As components shrink, traditional coding methods fall short. CIJ offers a durable solution for lot coding on electronics, producing reliable, high-quality date/lot codes. IV4 Series vision sensors confirm the mark/code accuracy.

-

1Continuous Inkjet Printer MK-G Series

-

2Intuitive Vision System CV-X Series

-

3Vision Sensor with Built-in AI IV4 Series

Delicate Marking Surfaces

In electronics, marking delicate surfaces with traditional printing methods can cause damage. CIJs provide a non-contact printing solution that delivers uncompromising accuracy and quality.

Curious about our pricing?

Click here to find out more.

CIJ for Electrical Components & Electronics

CIJs have the ability to consistently produce legible codes that meet regulatory requirements. They also provide great adhesion and quality on multiple materials, offering simple integration on different production lines. Regardless of the size or complexity of your production process, CIJs can easily be integrated without causing disruption, making them particularly useful tools for manufacturers, where precision and efficiency are crucial.

Discover more about this product.

Click here to book your demo.

FAQs about Marking for Tracking and Traceability in the Electrical Components & Electronics Industry

How Does KEYENCE CIJ Support Lot Coding on Electronics for Traceability and Quality Control?

KEYENCE CIJs can easily print high quality lot/batch codes and barcodes on products to provide traceability and quality control throughout the entire process.

What Features Does MK-G Series Offer to Meet the Stringent Requirements of Electrical Components Date Coding and Marking?

The MK-G Series, with its specialized micro nozzle MK-G1100, ensures consistent date coding for electronic components on small and uneven surfaces, facilitating traceability of electrical components. KEYENCE’s IV Series vision systems ensure accuracy by working with the MK-G Series.

How Does Continuous Inkjet Coding Technology Contribute to Efficient, Error-Free Lot Code Marking for Electronic Components?

Continuous inkjet lot coding on electronics uses high-speed, compact printers that are easily integrated into lines to apply ink droplets onto moving products, ensuring clear date codes for tracking and traceability.

What Unique Challenges Does the Electrical Components and Electronics Industry Face Regarding Coding and Marking, and How Does KEYENCE Address Them with Its MK-G Series printer?

Key challenges include miniaturization, quality on delicate surfaces, and regulatory compliance. KEYENCE CIJs use a dot quality system, measuring 10 times per second, for consistent high-quality prints without damage.

Can Continuous Inkjet Printers Accommodate the Various Small Surfaces Commonly Found in Electrical Components and Electronics?

Yes, KEYENCE can use the specialized micro nozzle MK-G1100, which can print tiny codes with extreme accuracy. This makes it ideal for marking on small surfaces such as circuit boards, chips, and connectors.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.