Continuous Inkjet Printers / Case Coder

Coding on Chemical Packaging

For coding on chemical packaging, accuracy and legibility are crucial for both safety and compliance with regulations.

KEYENCE Continuous inkjet printers (CIJs) provide consistent coding for chemical packaging, from bottles to drums. Self-troubleshooting ensures quick issue resolution and continuous high-quality chemical date coding. Automatic cleaning prevents clogs and malfunctions and seamless operation in harsh chemical environments.

Date Coding and Marking on Chemical Packaging

Glass Bottles

Proper labeling of glass bottles with date codes and lot numbers is crucial. KEYENCE industrial inkjet printers offer durable, high-quality printing on glass surfaces. Their non-contact technology ensures accurate chemical date coding on curved or uneven bottles.

Printing example

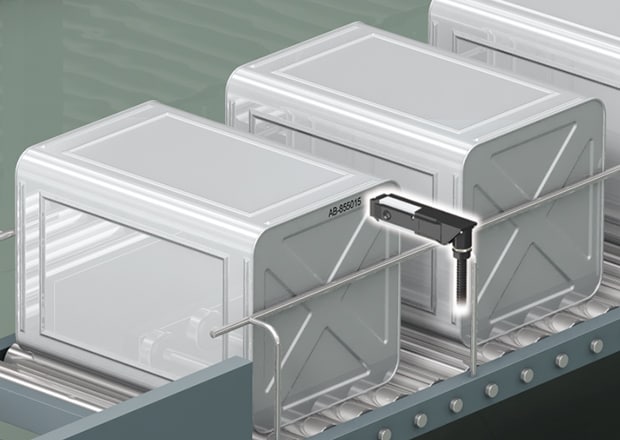

Installation example

Metal Cans

Metal cans are durable, protective, lightweight, and cost-effective. KEYENCE CIJs ensure high-quality codes on metal cans in harsh conditions by monitoring break point and dot condition 10 times per second.

Printing example

Installation example

Hard Plastic Containers

Hard plastic containers are popular for packaging due to their durability. KEYENCE CIJs efficiently mark on hard plastic surfaces like polypropylene containers with high speed and quality to ensure clear and durable codes.

Printing example

Installation example

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking for Chemical Industry

Use of Corrosive or Reactive Chemicals

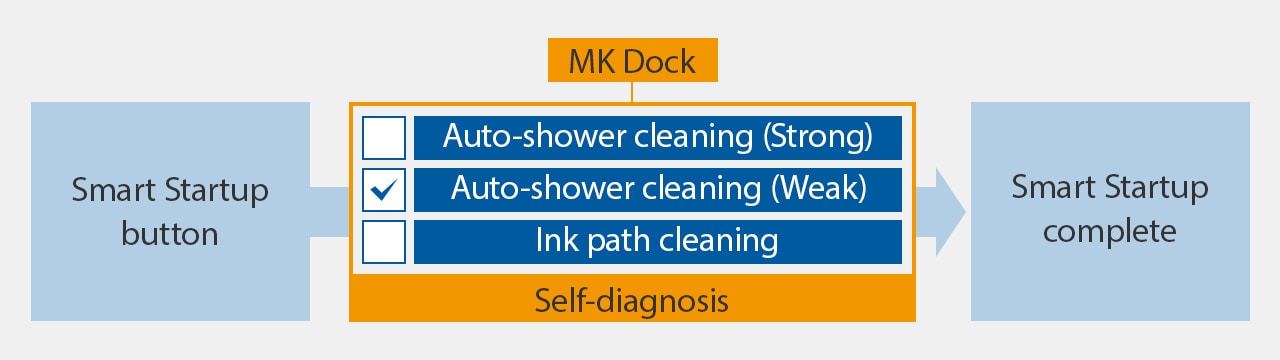

Traditional CIJs require frequent maintenance due to clogging. KEYENCE CIJs, with self-diagnostics and automatic cleaning before shutdown, eliminate guesswork and reduce maintenance.

Operating in Extreme Conditions

Printers face harsh conditions like strong chemicals and extreme temperatures. KEYENCE CIJs, with IP55 rated heads and controllers are able to withstand even the most dusty and wet environments.

Coding on Curved or Uneven Surfaces

A key challenge in coding on chemical packaging is printing on curved or uneven surfaces, especially in industries with varied product shapes. KEYENCE CIJs use non-contact technology for accurate, clear coding on such surfaces.

Curious about our pricing?

Click here to find out more.

CIJ for Chemical Packaging

Printing high-quality codes on various packaging materials is crucial in the chemical industry for product identification and traceability. KEYENCE CIJs adapt to various packaging materials like plastic, metal, and glass, ensuring clear codes on any surface. Self-troubleshooting detects and corrects issues preemptively. The automatic cleaning function and self-diagnostic capabilities reduce downtime and improve efficiency.

Discover more about this product.

Click here to book your demo.

FAQs about Date Coding in the Chemical Industry

What Specific Features Does the MK-G Series Offer in Its Coding and Marking in the Chemical Industry to Enhance Production Efficiency and Safety?

The MK-G Series offers ease of use, self-troubleshooting, robustness in harsh conditions, and accurate coding on chemical packaging for product safety information and traceability, resulting in increased uptime.

What Makes the MK-G Series Suitable for Operation and Coding on Chemical Packaging in Dirty or Wet Conditions?

KEYENCE's MK-G Series IP55 and MIL drop-rated print heads and console ensure robust performance in harsh environments, and quick-drying ink helps maintain print quality on the packages.The internal sensors constantly monitor break point and dot condition to ensure high-quality codes.

How Does the Continuous Inkjet Printer Assist Users in Troubleshooting Sudden Errors Encountered in Date Coding for Chemical Packaging Operations?

CIJs offer self-troubleshooting capabilities and free web remote monitoring and operation capabilities, making maintenance and cleaning procedures easier. Automatic cleaning functions can also be activated before shutting down the printer, saving time and effort for users.

Are KEYENCE's CIJ Coding and Marking Solutions Compatible with Various Packaging Materials Used in Chemical manufacturing?

KEYENCE's CIJ coding on chemical packaging solutions works with various packaging materials in the chemical industry, including plastic bottles, containers, bags, boxes, labels, and materials like PVC, polyethylene, and PET.

What Are the Main Challenges Faced When Printing Lot Codes and Dates Codes on Industrial Chemical Packages?

Corrosive or reactive chemicals can damage equipment and surfaces. Chemical coding and marking can take place in harsh conditions and on a variety of surfaces, including curved and uneven ones.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.