Continuous Inkjet Printers / Case Coder

Coding on Automotive and Aerospace Parts

For automotive and aerospace parts, traceability is an essential aspect of quality control, helping to identify and track specific parts throughout the manufacturing process and in the event of a recall. This is where coding on automotive and aerospace parts plays a crucial role.

Continuous inkjet printers can reliably print batch numbers, serial numbers, and other important information accurately in any environment.

Discover more about this product.

Click here to book your demo.

Date Coding and Marking on Automotive and Aerospace Parts

Metal Products

In manufacturing, strict regulations ensure metal product safety and quality, often requiring date coding. Industrial inkjet printers guarantee traceability with accurate, fast coding, eliminating errors and maintaining high-quality codes even in harsh environments.

Marking aluminum wheels

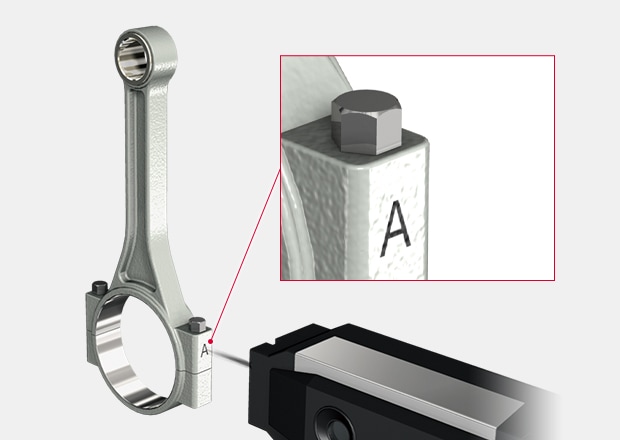

Marking the rank on a connecting rod

Piston

The rank for assembly in a later process is marked as a character string and 2D code.

Muffler

The muffler size and specifications vary depending on the vehicle that the muffler will be installed in, so marking is performed for identification.

Spring

An inkjet printer can be used to apply color to springs. This can be used to identify different products having the same shape.

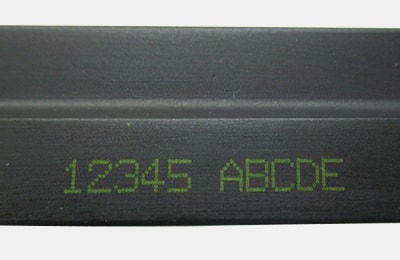

Extrusion-Molded Products

Extrusion-molded products need precise marking (lot numbers/serial numbers/barcodes) to avoid recalls and compliance issues. KEYENCE CIJ printers ensure high-quality marks by monitoring break points and dot conditions, guaranteeing adhesion and print quality.

Timing belt

The inkjet method is effective due to the concerns regarding damaging rubber timing belts.

Tires

Since laser markers are not effective on all types of rubber, using an inkjet printer is an effective method of marking tires.

Wiper blade

Marking is performed on the rubber component of the wiper blades. The manufacturing speed is fast enough during extrusion molding that other marking methods cannot keep up. An inkjet printer would be the most effective means of marking this type of part.

Parts

Parts differ in materials, shapes, and finishes, making accurate marking challenging. Traditional methods lack durability and precision. KEYENCE CIJs integrate seamlessly into production lines, ensuring legible and compliant coding on automotive and aerospace parts.

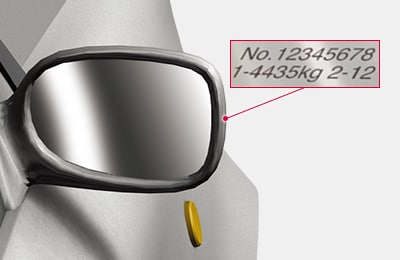

Side mirror

Marking is performed on the back surfaces of the side view mirrors. Conventionally, this marking was performed by hand, but this process can be automated by using an inkjet printer, which can lead to increased production.

Switches

These switches are installed in the vehicle's dashboard. Marking with an inkjet printer can be used to prevent problems such as friction after assembly.

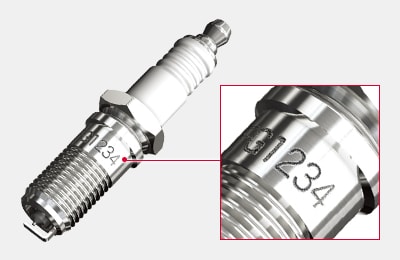

Spark plug

Marking to identify spark plugs for use in different vehicles is performed on the cylindrical surface.

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking for Automotive and Aerospace Industry

- Automotive and Aerospace Industries are Highly Regulated

The automotive and aerospace industries are tightly regulated due to potential risks. Minor automotive parts date coding errors can cause recalls, delays, or safety hazards. CIJ printers ensure legible, compliant codes on different materials for various applications. - Harsh Production Environments

Production lines operate at high speeds and extreme temperatures, challenging traditional coding methods. KEYENCE's MK-G Series, with a MIL standard drop-rating and IP55-rated print head, ensures durability under these conditions. - High Production Speeds and Volumes

The automotive and aerospace industries struggle with coding due to high quotas, limited staff, and maintenance needs. KEYENCE CIJ printers with self-maintaining smart docks boost productivity, freeing up skilled staff, and ensure fast, accurate coding.

Curious about our pricing?

Click here to find out more.

CIJ for Automotive and Aerospace Parts and Components

CIJ printing technology offers fast and accurate automotive date coding, ensuring no compromise on print quality. With strict regulations in these industries, it provides a reliable solution for product traceability and compliance.

One of the key advantages of using CIJ in these industries is its robust performance in harsh environments. The IP rating and MIL impact-resistant print head of KEYENCE's MK-G Series make it suitable for use in dusty or wet conditions without compromising on print quality.

Discover more about this product.

Click here to book your demo.

FAQs about Date Coding in the Automotive and Aerospace Parts

What Are the Benefits of Using KEYENCE's CIJ in the Automotive Industry?

The benefits include compliance with regulations through accurate date coding on automotive and aerospace parts for traceability and product safety, and minimal maintenance requirements.

How Does the MK-G Series Address the Challenges of Harsh Environmental Conditions Typical in the Automotive Industry?

The MK-G Series print head and touch screen meet MIL drop standards. The MK-G print head, controller body, and touch screen also have an IP55 rating, making them ideal for harsh automotive conditions. These durable and reliable components ensure smooth date coding on automotive and aerospace parts even in demanding environments.

How Does the MK-G Series Support User-Friendly Coding and Marking Solutions for the Automotive Industry?

The MK-G Series offers user-friendly date coding on automotive and aerospace parts, featuring minimal human interaction, seamless production line integration, self-diagnostics, and automatic maintenance.

How Does the Continuous Inkjet Printer Enhance Efficiency in Automotive and Aerospace Coding and Marking Processes?

There are several key benefits: improved throughput or marking speed, ease of maintenance and cleaning, and accuracy and clarity of date codes.

How Does the Continuous Inkjet Printer Ensure Quality Date Coding on Automotive and Aerospace parts?

KEYENCE CIJs feature a built-in monitoring system that checks for break points or dot conditions up to 10 times per second. It offers non-contact printing and easily integrates with other KEYENCE inspection equipment.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![MK-U6000 Collection of Inkjet Printer Introduction Examples [Automobile industry Edition]](/img/asset/AS_74789_L.jpg)