Printing and Coding on Snack Packaging

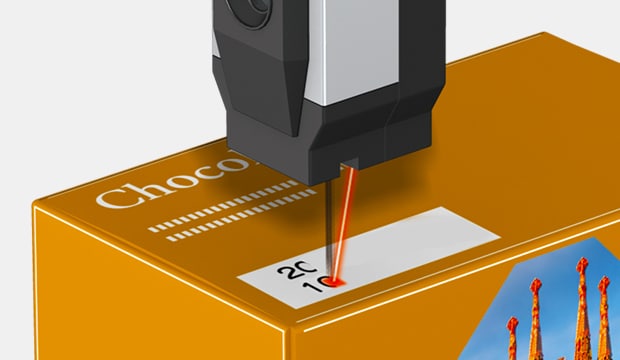

Continuous inkjet printers (CIJs) are essential for coding in snack and confectionery production lines, where high speeds can often result in coding errors. Requiring speed and precision to meet production targets, confectionery products and snack production lines are prone to coding errors.

KEYENCE offers its CIJ the MK-G Series for fast, accurate, and durable codes that are ideal for eliminating the challenges in snack packaging.

Lot/Date Coding and Marking on Snack Packaging and Pouches

The MK-G Series offers fast-drying ink for non-contact printing on:

- Jars

- Tins

- Cans

- Cartons

- Bags

- Pouches

Pouches

Packaging film

Cartons

Form-filled packages

Heat-sealed packages

Its ink system reduces waste and solvents, while self-diagnostics enhance performance and minimize downtime. With its automatic ink particle optimization feature, the MK-G Series can ensure that every code is printed clearly and accurately, regardless of the shape. A viscosity sensor and conditioning tank system maintains stable print quality and prevents ink dilution, which is vital for accurate lot/date codes and avoiding recalls.

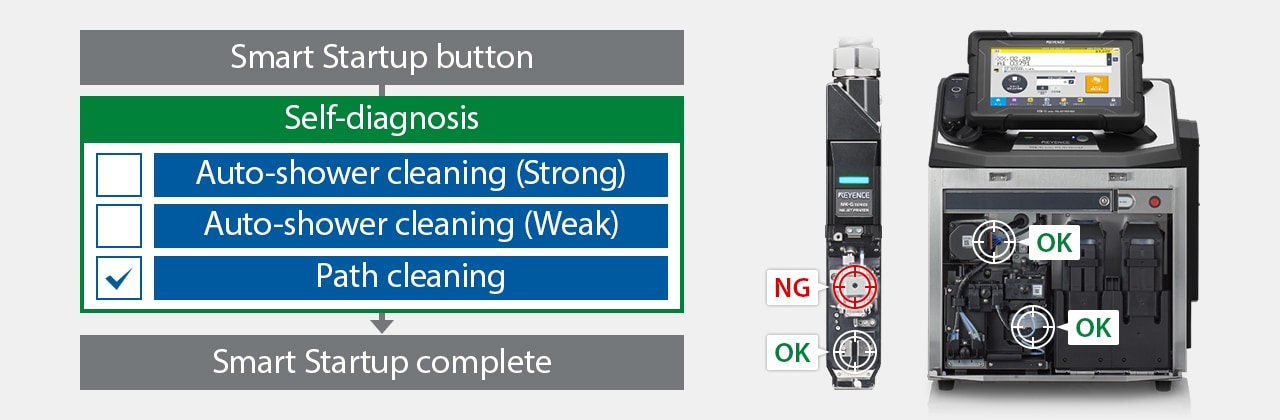

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

We’re here to provide you with more details.

Reach out today!

Challenges in Lot/Date Coding on Snack Packaging

Printing Environment

In printing/date coding on snack packaging, salt, grease, etc. can lead to quality issues. Ingress protection and other features in the MK-G Series prevent external interference in challenging environments.

Varying Packaging Requirements

Industrial inkjet printers feature a reliable product-switching system for speed and accuracy, reducing coding errors. The MK-G Series simplifies this with a smart assist camera and a user-friendly interface to eliminate user error.

Registering images using the operation assist camera

Character strings can be read with the camera to change print content quickly and accurately.

Speed and Accuracy

Coding and marking on snack packaging and pouches require high-speed production. The MK-G Series delivers rapid printing without compromising print legibility or durability.

Regulatory Compliance

KEYENCE continuous inkjet printers’ produce high-quality and consistent marks that ensure proper labeling for traceability and regulatory compliance.

Curious about our pricing?

Click here to find out more.

CIJs for Printing on Snack Packaging and Pouches

Our CIJs for the food and beverage industry deliver speed and accuracy requirements for coding and marking on snack packaging and pouches. The automatic shower cleaning function prevents blurred, smeared, or incomplete characters from arising by cleaning the key print head components that accumulate ink and dirt. A dedicated camera facilitates rapid print settings and character string changes while eliminating common mistakes during changeover and setup.

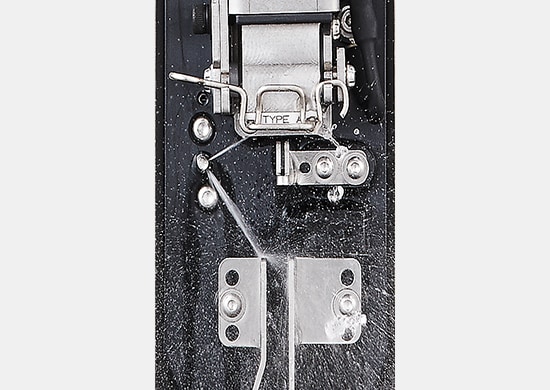

Conventional head cleaning

Manual cleaning was required to wash residual ink off the inside of the head.

Auto-shower cleaning

In addition to cleaning the ink paths, the key parts of the head are also subject to high-pressure cleaning. This negates the need for manual cleaning.

Discover more about this product.

Click here to book your demo.

FAQs about Date Coding in The Snack Packaging Industry

How Does Date Coding on Snack Pouches, Bags, and Packaging Enhance Production Efficiency?

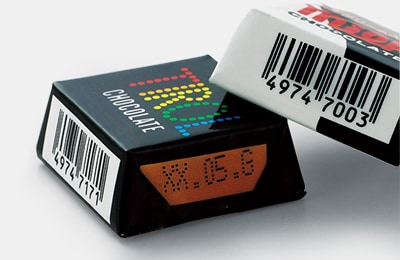

CIJs enhance production efficiency by coding snack packaging quickly with essential information like manufacturing dates, expiration dates, and lot numbers, ensuring quality control and traceability.

How Do CIJs, Like the MK-G Series, Ensure High-Speed and Accurate Coding on Various Packaging Materials Used in the Snack Industry?

The MK-G Series features a viscosity sensor and conditioning tank that prevents ink dilution, ensuring stable print quality during extended use.

How Does CIJ Technology Prevent Costly Errors and Reduce Downtime for Snack Manufacturers?

KEYENCE CIJ technology guarantees high-quality prints with external inspection support to minimize errors. The IP55-rated printhead/controller resists dust and water, ensuring reliable performance. The MK Dock unit enables self-diagnosis and automatic cleaning, reducing downtime and allowing skilled technicians to focus on more critical production tasks.

What Maintenance Options Are Available to Ensure Error-Free Coding and Marking on Snack Packaging and Pouches?

The MK-G Series offers maintenance options for snack packaging production lines, including automatic error diagnosis, troubleshooting, automated print head cleaning, and toolkit-free part replacement. The MK-G Series has an intuitive, touch-screen interface with videos for easy setup, operation, and maintenance, making it possible for anyone to operate, maintain, and troubleshoot the system.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)