Coding on Pet Food and Animal Feed Packaging

In the pet food industry, proper packaging coding ensures product quality, traceability, and brand recognition. However, diverse packaging formats present unique coding challenges.

KEYENCE offers coding on pet food and animal feed packaging solutions with the MK-G Series continuous inkjet printers (CIJ). Perfect for high-speed production, it prints on various materials and has a self-cleaning function, minimizing downtime and maintenance costs.

Lot Coding and Marking on Pet Food and Animal Feed Packaging

Metal Cans

Metal cans are popular for pet food packaging due to their durability. With an intuitive interface and automated self-maintenance, ensure high-quality, consistent markings at high speeds with the MK-G-Series.

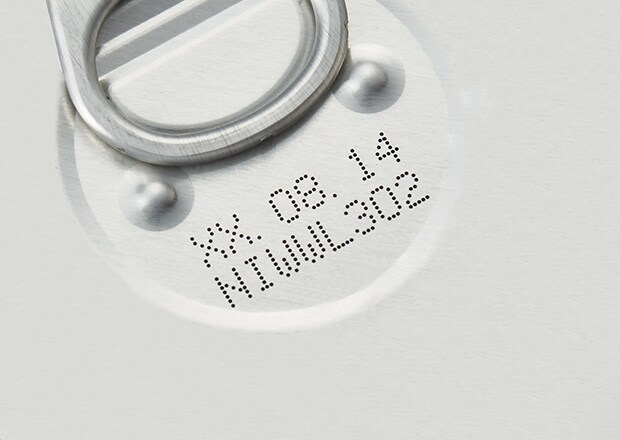

Printing example

Installation example

Paper Bags

The MK-G Series simplifies the paper bag coding process, requiring no technical skills for operation or maintenance, reducing downtime and costs by eliminating service contracts. Recovery is easy with simple guidance or automated troubleshooting.

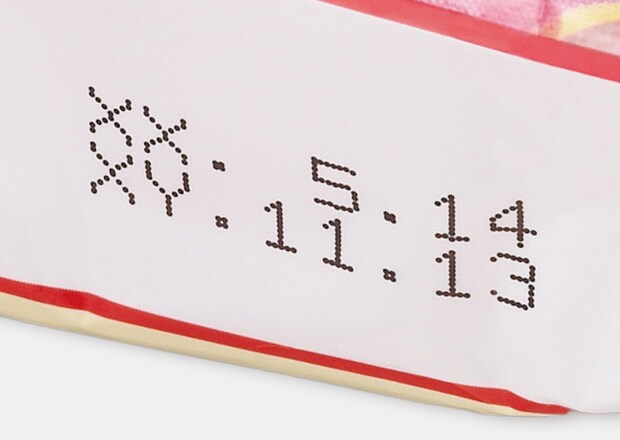

Printing example

Installation example

Chub Packs

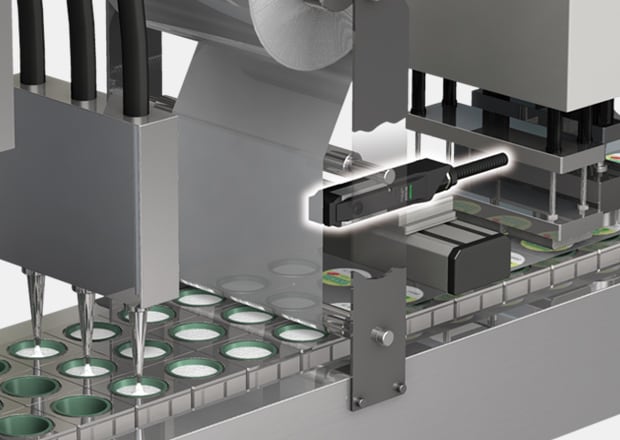

Chub packs are flexible, cylindrical bags. The unit uses non-contact printing and adaptive settings to ensure high-quality coding on pet food and animal feed packaging surfaces, including curved or uneven packs.

Printing example

Installation example

Rigid Plastic Bottles and Cups

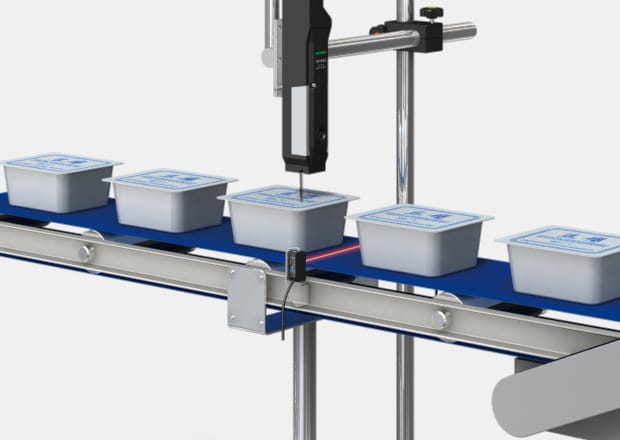

Installing an inkjet printer on a conveyor belt enables companies to mark hundreds of plastic bottles and cups per minute. Parallel-filled products can be marked by traversing the inkjet print head.

Printing example

Installation example

Flexible Plastic and Foil Bags and Pouches

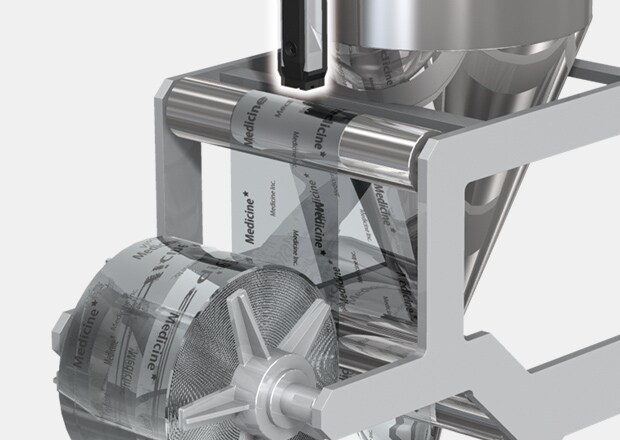

Our CIJ offers variable data printing, marking accurate expiration dates and batch numbers on each package. This saves time and reduces human error by eliminating manual labeling of individual containers of varying shapes.

Printing example

Installation example

Cartons

The MK-G Series offers reliability with high-speed and durable carton printing, sensing ink particles 10 times per second to ensure high-quality print in changing conditions.

Printing example

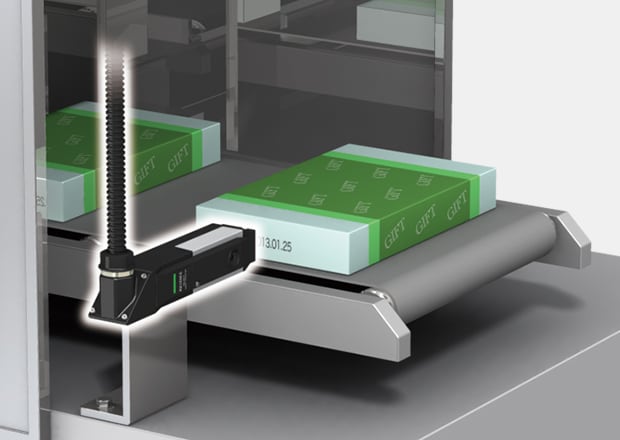

Installation example

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Pet Food and Animal Feed Packaging

Variable Packaging Surfaces

Each surface, like plastic bags or metal cans, requires a unique coding approach. The MK-G Series has a conditioning tank system that collects solvent after cleaning, which helps maintain stable print quality.

Production Environments

A major pain point in production is frequent maintenance. The MK-G features self-diagnostic routines and auto-cleaning, saving technicians time and ensuring consistent coding on pet food and animal feed packaging.

High-Speed Production

With rising consumer demand, manufacturers seek to optimize production. Our industrial inkjet printers provide performance analytics, monitoring hourly operation status, including error counts, operating hours, temperature, and viscosity for up to 100 days.

Coding Compliance Requirements

Maintaining legibility on codes to ensure compliance is vital. Our MK-G Series automatically senses and adjusts ink particles, ensuring clear codes even in varying production environments.

Curious about our pricing?

Click here to find out more.

CIJ for Pet Food and Animal Feed Packaging

The pet food and animal feed packaging industry is constantly evolving. Accurate coding on pet food and animal feed packaging is crucial for product integrity and traceability.

KEYENCE CIJs for the food and beverage industry offer long-lasting, legible codes throughout a product's shelf life. Advanced sensors automate maintenance and troubleshooting, reducing downtime and errors. Ideal for high-speed printing, these printers can code up to 470 m 1,542 ft of single-line text per minute. This makes them suitable for large production volumes and fast-paced manufacturing environments.

Discover more about this product.

Click here to book your demo.

FAQs About Date Coding in the Pet Food and Animal Feed Industry

What Is the Importance of Lot/Date Coding on Pet Food and Animal Feed Packaging?

Lot/date coding on pet food and animal feed packaging is essential for product traceability, expiration date tracking, and regulatory compliance in the pet food and animal feed industry.

What Are the Key Factors to Consider When Selecting a Date-Coding Solution for Pet Food and Animal Feed Packaging?

Key factors to consider include the speed and ease of maintenance, packaging materials, production line speed/throughput, and ease of integration into production lines.

Can the MK-G Series Accommodate the Diverse Packaging Materials Used in the Pet Food and Animal Feed Industry?

Yes, the MK-G Series can accommodate various packaging materials like pouches, paper sacks, and metal cans, and integrates seamlessly into existing lines.

How Does KEYENCE CIJ Technology Reduce Cost and Downtime in Pet Food and Animal Feed Packaging Date Coding Operations?

Our MK-G Series printers have an IP55-rated head and controller for dust and water resistance, ensuring reliable operation in dirty and wet environments, and reducing cost and downtime.

How Does the MK-G Series Support Compliance with Pet Food and Animal Feed Packaging Coding and Marking Industry Regulations?

The CIJ ensures compliance with regulations by providing accurate, legible coding for consumer safety and traceability. It prints high-quality codes at high speeds that marketing will love.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.