Coding on Packaged Foods Industry

Coding on packaged foods ensures regulatory compliance and helps product traceability and consumer safety.

KEYENCE CIJs (Continuous Inkjet Printers) feature automatic maintenance and troubleshooting, minimizing service costs/downtime. Renowned for top-tier print quality and reliability, they ensure perfect dot quality and can print high-quality codes on curved, irregular, and textured surfaces.

Date Coding and Marking on Packaged Food

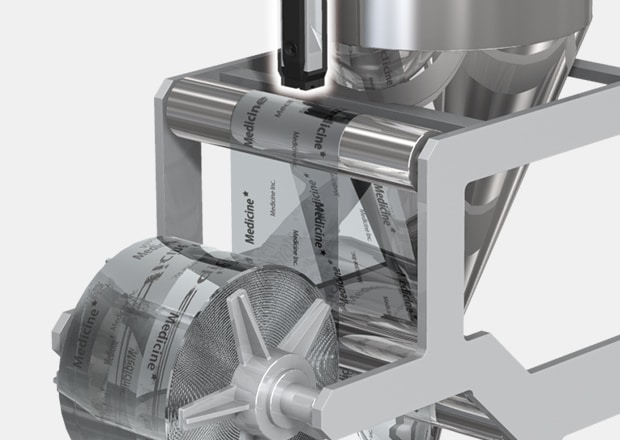

Films

Packaged foods date coding mistakes can cause spoilage and customer dissatisfaction. KEYENCE CIJs ensure compliance with strict date coding regulations, providing reliable, high-quality, and accurate date and lot codes on packaged foods.

Printing example

Installation example

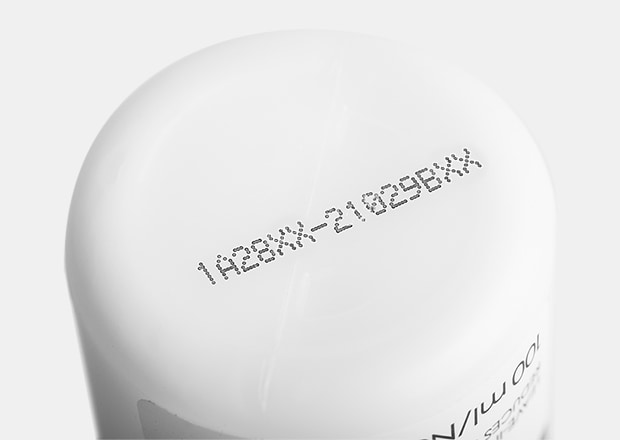

Containers and Caps

In coding on packaged foods, container shapes can challenge manufacturers. KEYENCE industrial inkjet printers solve this with non-contact printing, ensuring clear, legible product information on curved surfaces.

Printing example

Installation example

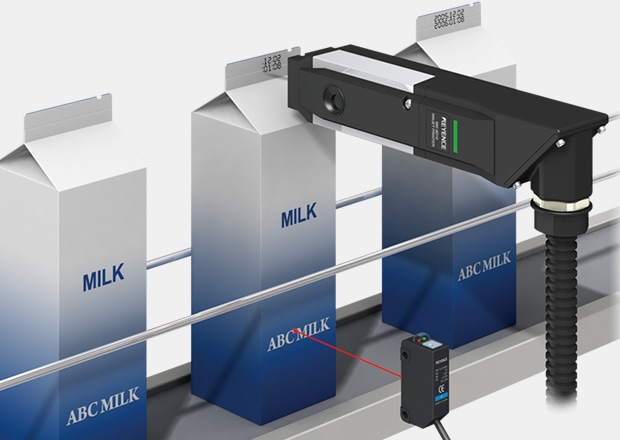

Cartons

Incorrect or missing date codes can spoil carton-packaged foods. KEYENCE CIJs ensure accurate, visible date codes on various surfaces with non-contact printing technology.

Printing example

Installation example

Hard Plastic Containers

Hard plastic containers need durable date codes for traceability. KEYENCE CIJs mark PP and PET containers with high throughput/marking speed, ensuring quality in high production volumes.

Printing example

Installation example

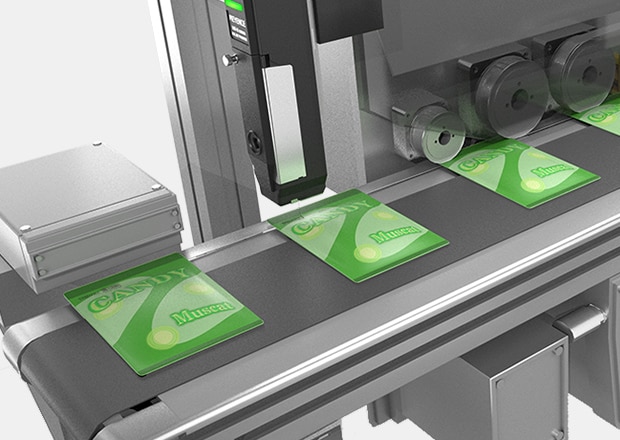

Flexible Plastics

Stamps or labels are hard to use on flexible plastic packaging due to the uneven surface. KEYENCE CIJs offer automatic maintenance, troubleshooting, and easy nozzle replacement, reducing downtime and increasing productivity.

Printing example

Installation example

Pouches

Traditional methods are often expensive, time-consuming, and ineffective. Stamps/labels may not adhere well to flexible pouches. KEYENCE CIJs print on various packaging materials, including PET, PP, PE, and more.

Printing example

Installation example

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking for Packaged Food Industry

- Packaging Material Limitations

Each material's unique properties demand different printing approaches. KEYENCE CIJs deliver high-quality, smudge-resistant coding on packaged foods and can print on curved, irregular, and textured surfaces. - Regulatory Requirements

Non-compliance with regulations leads to fines, recalls, lost contracts, and reputation damage. KEYENCE CIJs can work in tandem with vision systems to easily print and verify batch numbers and expiry dates, ensure traceability, and identify defective products. - Maintaining Coding Consistency Across Different Production Lines

A major challenge in coding on packaged foods is ensuring consistency across different production lines. KEYENCE CIJs eliminate rework and scrap by integrating across varying lines. They mark multiple materials with dates, lot numbers, and safety codes.

Curious about our pricing?

Click here to find out more.

CIJ for Packaged Food

KEYENCE CIJs stand out for their fast and accurate coding capabilities. They enable manufacturers to identify and trace defective or substandard products. This feature is crucial in the packaged food industry as it ensures that only high-quality products reach consumers.

CIJ technology minimizes the chances of human error in packaged food coding and marking processes. This leads to more reliable and efficient coding, ensuring that all packaged food products are accurately labeled with the correct information.

Discover more about this product.

Click here to book your demo.

FAQs about Date Coding in the Packaged Food Industry

What Are the Date Coding and Lot Coding Requirements in the Food Packaging Industry?

Packaged foods date coding indicates shelf life, expiration date, and production batch. Packaged food coding and marking are essential for tracking, traceability, and ensuring food safety and quality.

Can KEYENCE's MK-G Series CIJ Coder Accommodate the Diverse Packaging Materials Used in the Pre-packaged Food Industry?

Yes, the KEYENCE MK-G Series CIJ coder is designed to accurately print on a wide range of packaging materials including paper, cardboard, plastic, metal and even glass surfaces.

What Specific Industry-First Features Does KEYENCE's CIJ Introduce to Enhance Production Efficiency and Reliability in the Packaged Food Manufacturing Industry?

KEYENCE CIJs have introduced; MIL standard-compliant impact-resistant print head structure, a self-diagnosing and troubleshooting smart dock, a backup power module, and an event recording function.

What Are the Benefits of Using CIJ Solutions for Quality Control and Product Identification in Date Coding in the Packaged Food Sectors?

There are several benefits: easy integration with vision systems/inspection equipment to verify presence of printed content and enhance compliance with regulations, no compromise on accuracy for speed, traceability and product safety, and minimal down time for cleaning and maintenance.

How Does KEYENCE's MK-G Technology Contribute to Reducing Downtime and Increasing Productivity in Packaged Food Date Coding?

KEYENCE's MK-G technology minimizes downtime in packaged foods date coding with self-diagnosing capabilities and step-by-step instructions and videos, enabling easy troubleshooting, free printer monitoring network connectivity, rapid nozzle clog recovery with a patented one-touch nozzle replacement, and email alerts for unmatched production visibility.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)