Coding on Meat and Poultry Packaging

KEYENCE continuous inkjet printers (CIJs) are designed to bring maximum contribution to the stringent production requirements of meat and poultry packaging.

Our CIJ solutions produce high-quality printing and coding on meat and poultry packaging to achieve your operational goals in a highly regulated industry.

Lot/Date Coding and Marking on Meat and Poultry Packaging

Trays

Traditional coding methods struggle with trays due to irregular surfaces. The MK-G Series uses a non-contact method of printing to help reliably print on different shapes and surfaces.

Printing example

Installation example

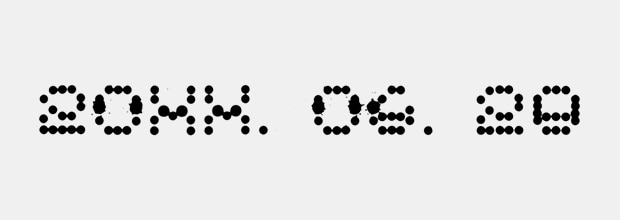

Printing example

Chub Packs

A key challenge in coding and marking chub packs is maintaining consistent quality with varying surfaces and temperature levels. The MK-G Series addresses this with self-diagnostics and automatic cleaning, ensuring high-quality printing.

Printing example

Cartons/Sleeves

Traditional manual stamping and labeling on cartons are slow and error-prone. The MK-G Series contains internal sensors that check ink quality multiple times per second, allowing it to print at high speeds while maintaining clean codes.

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Meat and Poultry Packaging

Skilled Labor Shortages

Skilled labor shortages increase downtime for printers requiring specialized skills and training. With self-diagnosing and automatic troubleshooting features, the MK-G Series allows staff to focus on other complex tasks.

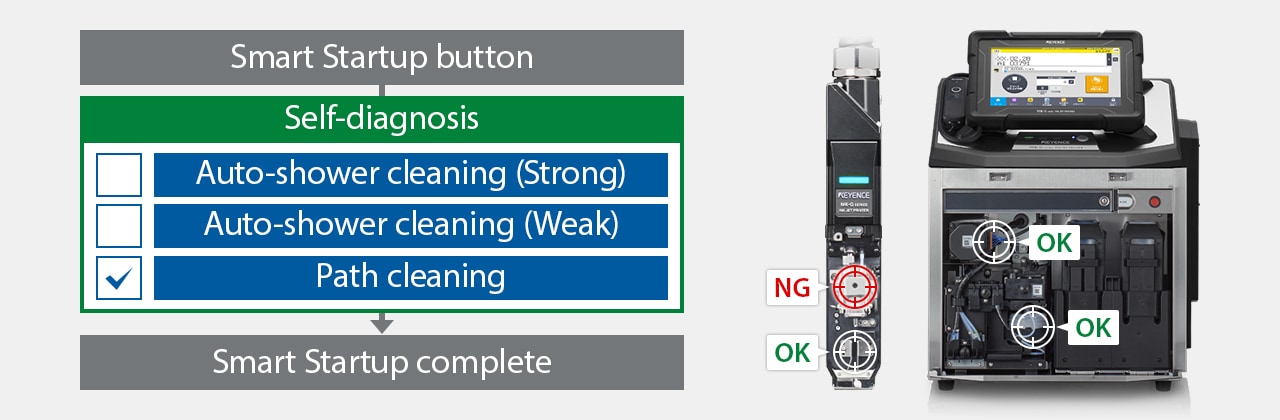

Self-Diagnosis Followed by Automatic Cleaning When Necessary

INDUSTRY FIRST Smart Startup

To start the MK-G Series, simply press the SmartStartup button. The printer will automatically obtainthe device status and select the necessarycleaning method. Cleaning is performed only whenrequired and the minimum amount of solvent isused, significantly reducing running costs.

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

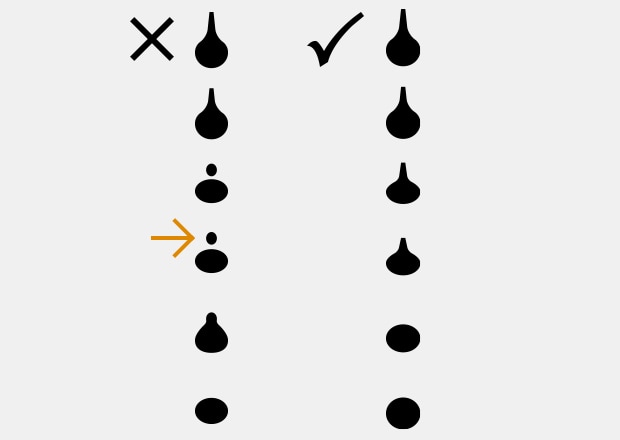

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Print Quality

Coding and marking on meat and poultry packaging is challenging due to extreme temperatures and rough handling. MK-G Series continuous inkjet printers ensure consistent, legible results by using internal sensors to monitor ink quality and viscosity levels.

Less-than-optimal state of particles

Optimal particle state

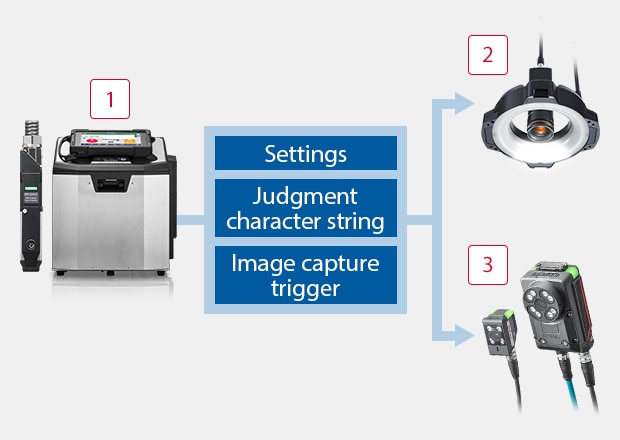

Easily link to a print inspection device with just a LAN cable

Coding Accuracy

With built-in features like easy connection to an external inspection device, the MK-G Series helps eliminate challenges relating to print and coding errors.

-

1Continuous Inkjet Printer MK-G Series

-

2Intuitive Vision System CV-X Series

-

3Vision Sensor with Built-in AI IV4 Series

Challenging Environment

Changes in environmental factors, like temperature, can cause ink adhesion and drying issues. MK-G Series industrial inkjet printers feature ink technology that endures in various conditions.

Curious about our pricing?

Click here to find out more.

CIJ for Meat and Poultry Packaging

KEYENCE CIJs comes with standard and advanced features that guarantee high speed and quality printing, support different types of print and coding jobs, and integrate with existing production lines. Trust us as a reliable partner for continuous inkjet printers that are easy to operate and maintain through illustrated instructions and self-troubleshooting and diagnosing functions.

Discover more about this product.

Click here to book your demo.

FAQs about Date Coding in the Meat and Poultry Industry

How Does Coding on Meat and Poultry Packaging Enhance Traceability and Compliance?

Quality coding on poultry packaging ensures product information and data, such as barcodes and production dates, are legible and consistent for traceability and compliance requirements. This allows for a quick response in the event of a recall.

How Does the KEYENCE CIJ Coding and Marking Technology Improve Efficiency in Meat and Poultry Packaging?

CIJs for the food and beverage industry feature self-troubleshooting and automatic cleaning, which free up skilled labor, increasing output, and reducing downtime.

How Does the KEYENCE CIJ Ensure Accuracy and Durability in Lot/Date Coding on Meat and Poultry Packaging?

KEYENCE continuous inkjet printers ensure accurate, durable lot/date coding on meat and poultry packaging with reliable ink quality-sensing technology and an easy-to-use interface.

What Role Do Coding and Marking Play in Reducing Product Recalls in the Meat and Poultry Industry?

Clear and accurate product coding meets labeling requirements like allergen alerts and nutritional info, helping prevent allergic reactions for customers and ensuring food safety.

How Do Coding and Marking Contribute to Quality Control in Meat Production?

Coding and marking on meat and poultry packaging materials assists food processors, packers, and engineers in producing and packaging safe and healthy food products.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)