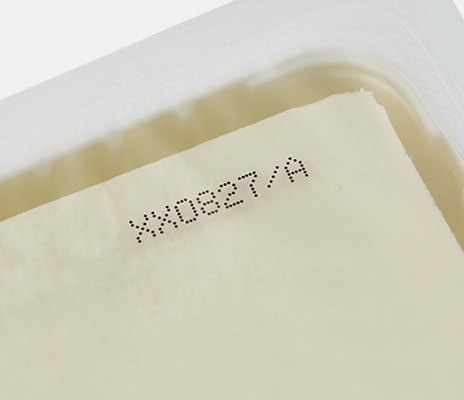

Coding on Fruit and Vegetable Packaging

As consumer and industrial demands for coding on fruit and vegetable packaging evolve, efficiency, quality, and compliance issues have driven manufacturers to seek better date/lot coding solutions.

KEYENCE CIJs for the food beverage industry offer high-quality, reliable lot coding and marking, ensuring traceability and product quality.

Lot Coding and Marking on Fruit and Vegetable Packaging

Flexible Plastics

Whether it’s LLDPE, HDPE, PVC, or other flexible plastic materials, the MK-G Series can accurately create marks to ensure traceability.

Shrink Wrap

The MK-G Series is a great solution for PVC or bio-based shrink-wrap packaging, as they add precise information and streamline supply chain tracking.

Pouches and Bags

Produce packaged in pouches and bags, such as carrots, apples, and frozen vegetables, can have durable lot codes and marks quickly applied with the MK-G Series continuous inkjet printers.

Form-filled packages

Packaging films

Pouches

Heat-sealed packages

Cartons

The MK-G Series provides clear marks on flat and curved cartons, such as expiration dates and other unique identifiers from the manufacturer.

Glass Bottles and Jars

Often used to store perishable foods, glass bottles and jars require legible expiration dates and lot codes. The MK-G Series printers achieve this at high speeds for mass production.

Cartons

Cartons

Glass bottles

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Fruit and Vegetable Packaging

Coding Across Different Industries Is Complex

Compliance in date and lot coding across varying industries comes with unique regulations. This calls for flexible coding technology that adapts to the regulations of a global market.

Various Packaging Types Can Be Difficult to Work With

Streamlining production, improving efficiency, and working with a variety of packaging types is a rising challenge for traditional coding methods.

Print Quality and Traceability Are Often a Problem

Traditional industrial inkjet printers often struggle to maintain print quality throughout the product life cycle. This often leads to consumer concerns and complications in managing recalls.

Environmental Factors Can Be Costly

Environmental conditions, such as temperature and humidity, can impact the costs and print quality of outdated coding techniques, a problem that modern coding solutions eliminate.

Curious about our pricing?

Click here to find out more.

CIJs for Fruit and Vegetable

The capabilities of continuous inkjet printers can overcome many of the challenges and demands stemming from fruit and vegetable coding and marking, including lower onboarding and training costs and reliable, high-quality performance. Built with self-troubleshooting and automatic maintenance and cleaning features, the MK-G Series is a leading continuous inkjet printer choice for manufacturers.

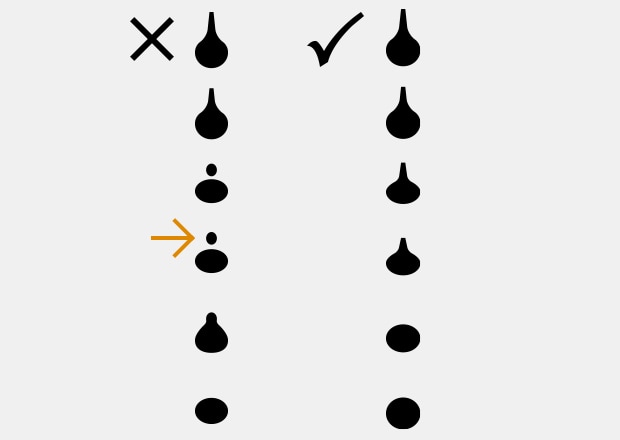

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

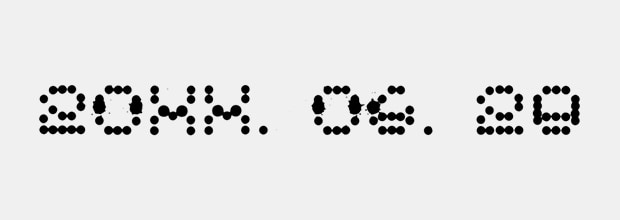

Offering simple operation and reliable efficiency for fruit and vegetable date coding, this CIJ can adapt to temperature changes, automatically wash down the inside of the print head, and limit exposure to chemicals to maintain quality and safety.

Less-than-optimal state of particles

Optimal particle state

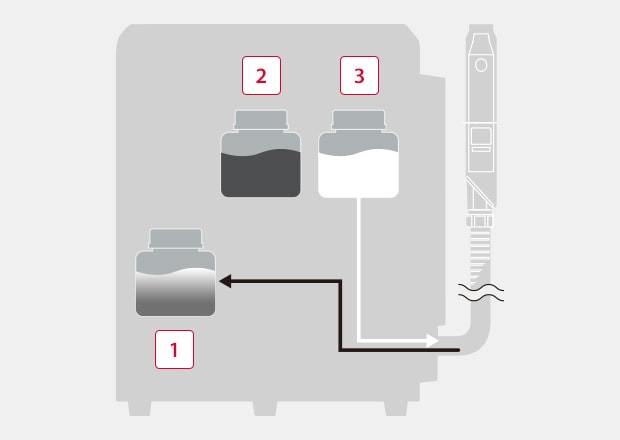

Conventional

When washing is performed, the ink viscosity decreases.

-

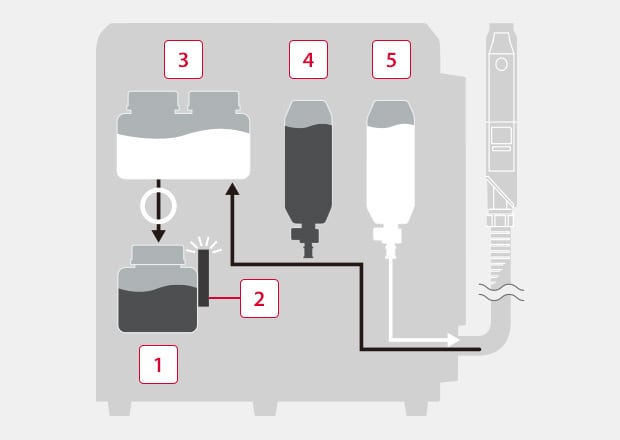

1Main tank

-

2Ink tank

-

3Solvent tank

MK-G Series

The conditioning tank is used for temporary storage to prevent dilution of the ink.

-

1Main tank

-

2Viscosity sensor

-

3Conditioning tank

-

4Ink cartridge

-

5Solvent cartridge

Discover more about this product.

Click here to book your demo.

FAQs About Date Coding in the Fruit and Vegetable Packaging Industry

Can CIJ Coding Withstand the Environmental Conditions in Produce Packaging Facilities?

Yes, IP-rated controller and print head offer unprecedented durability in the wet and dirty environmental conditions found around produce. Sensors also monitor dot quality 10 times per second to ensure consistent print quality in all temperatures.

Why Is Lot/Date Coding Important for Fruits and Vegetables?

Lot/date coding ensures traceability, informs consumers of product age or expiration, and is essential for compliance in food manufacturing and production.

What Are the Regulatory Requirements for Coding on Fruit and Vegetable Packaging?

Regulatory requirements include traceability, accurate labeling of origin, expiration dates, lot numbers, and adherence to food safety and quality standards.

How Can Date Coding Help Comply With Traceability Regulations in the Fruits and Vegetable Packaging Industry?

Date coding aids traceability regulations by managing product recalls, identifying production issues in specific batches, and tracking the origin and timing of the product.

How Do KEYENCE CIJ Printers Ensure Minimal Downtime in Date Coding and Marking Fruit and Vegetable Packaging Operations?

A few unique features make this possible, such as real-time monitoring, hands-free cleaning, automatic maintenance and troubleshooting. KEYENCE CIJs detect changes in ambient temperature and adjust dot quality/breakpoint on the fly to maintain optimal print quality and printer performance. This constant adjustment significantly reduces print quality issues and dirty printheads severely reducing the frequency of cleaning and downtime. Then, in the event it is needed, the unit can perform self-diagnostics and clean itself without maintenance intervention.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)