Coding on Dairy Packaging

The main challenge in the dairy industry is ensuring that products remain fresh and safe for consumption.

KEYENCE CIJs are robust and can withstand cold, wet dairy production environments. They provide reliable, high-quality date coding on dairy packaging with minimal maintenance, leading to higher efficiency and productivity. Easy integration ensures seamless implementation with minimal disruptions.

Date Coding and Marking on Dairy Packaging

Hard Plastic Containers

KEYENCE CIJs print in high quality on milk/cheese/yogurt containers and cartons despite the cold and wet environments by using advanced sensor tech to monitor dot breaks points 10 times p/sec. They self diagnose and troubleshoot to reduce downtime making them extremely easy to maintain.

Printing example

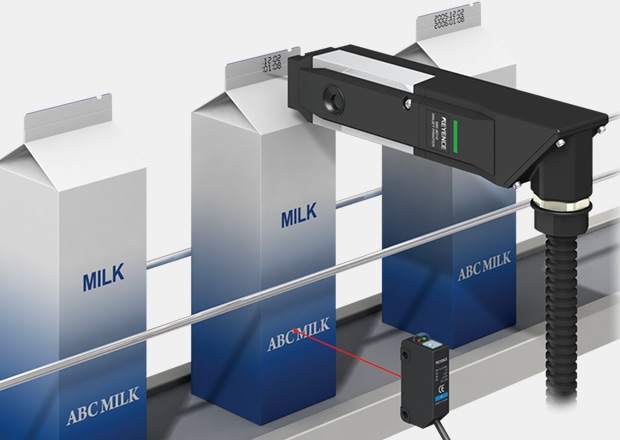

Installation example

Cartons

Dairy products are perishable and must be accurately labeled with best by or expiration dates. KEYENCE CIJs provide high-quality, non-contact printing on any surface, including curved or uneven ones, and reduce the need for human interaction.

Printing example

Installation example

Films

Coding mistakes can cause spoilage, contamination, and customer dissatisfaction. KEYENCE CIJs ensure compliance with FDA regulations, providing reliable, high-quality date and lot codes, perfect for the dairy industry.

Printing example

Installation example

Containers and Caps

The shape and size of containers and caps vary widely, making it difficult to code them accurately. Tackle this challenge by providing visible and accurate information with high-speed printing and adaptability to various surfaces with KEYENCE CIJs.

Printing example

Installation example

Flexible Plastics

Traditional marking methods like stamps or labels are difficult on flexible plastics. KEYENCE CIJs reduce downtime with automatic maintenance and troubleshooting, boosting productivity. Free printer monitoring network connectivity simplifies management.

Printing example

Installation example

Metal Cans

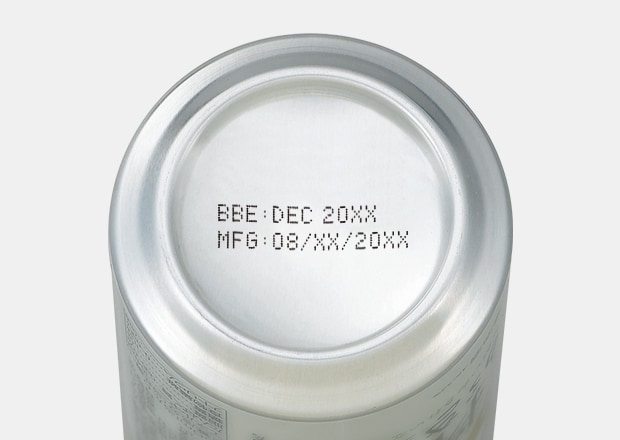

Metal cans are sometimes used for their durability and barrier properties. KEYENCE CIJs integrate easily into packaging lines, minimizing the need for specialized knowledge. They also support remote monitoring and control, offering convenience.

Printing example

Installation example

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking for Dairy Industry

Fast-Paced Nature of Dairy Production

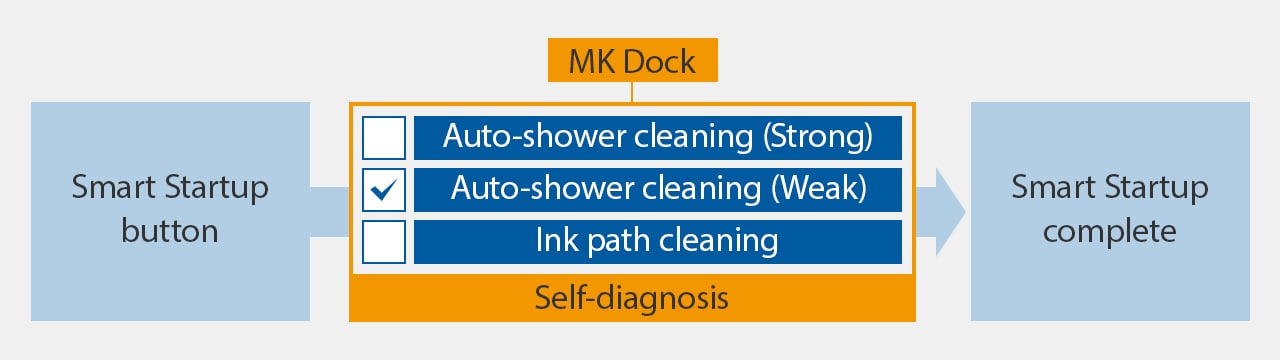

The dairy industry depends on rapid milk and dairy production. KEYENCE CIJs, with auto maintenance, monitoring, and troubleshooting, meet these needs, freeing up skilled technicians. One touch nozzle replacement allows for recovery from errors and clogs in a matter of seconds.

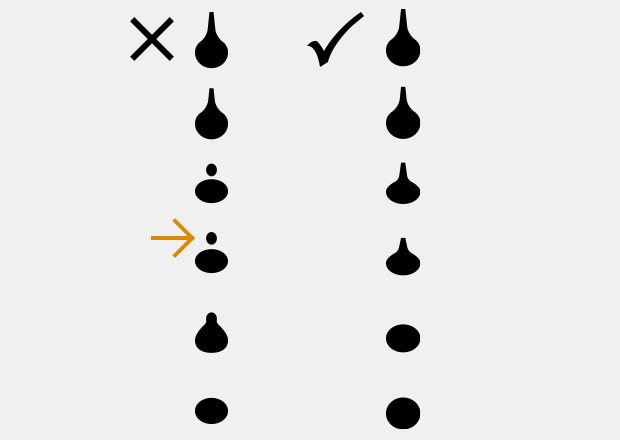

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Variety of Packaging Materials

The dairy industry uses materials like plastic, glass, metal, and paper. KEYENCE CIJs print on any surface, curved/uneven, without contact. Consistent coding is ensured by monitoring dot conditions 10 times p/second.

Less-than-optimal state of particles

Optimal particle state

Adverse Working Conditions

Dairy production facilities are often wet and cold, challenging traditional date coding on dairy packaging methods. KEYENCE CIJs' robust design with MIL Drop and IP-rated MK-G Series print head and controller can handle even the harshest environments.

Curious about our pricing?

Click here to find out more.

CIJ for Dairy

KEYENCE CIJs are the perfect solution for ensuring reliable and high-quality date and lot codes in the dairy industry. With minimal maintenance required, this technology helps

increase uptime and productivity in dairy production facilities.

The easy integration of KEYENCE CIJs into existing production systems makes it a hassle-free solution for dairy manufacturers. Additionally, these printers are designed to withstand harsh environments commonly found in dairy processing plants.

Discover more about this product.

Click here to book your demo.

FAQs about Date Coding in the Dairy Industry

What Is Dairy Date Coding, and Why Is It Important in the Dairy Industry?

Dairy date coding marks products with expiration dates to inform consumers of production dates and safe consumption periods. This is crucial in the dairy industry for maintaining freshness and safety.

How Does KEYENCE's CIJ Ensure Compliance with Date Coding/Expiration Date Marking Regulations in the Dairy Industry?

Dairy products follow strict regulations for manufacturing, expiration date coding, and tracking and traceability. KEYENCE CIJs adheres to regulation by printing high-quality, traceable codes throughout the supply chain.

Can MK-G Series Printers Accommodate Date Coding for Various Packaging Materials Used in the Dairy Industry?

Yes, MK-G Series printers can print on dairy packaging material surfaces like plastic, paper, and carton, even on curved or uneven surfaces, ensuring accurate dairy date coding for product safety and traceability.

What Are the Benefits of Using KEYENCE MK-G Series CIJ Printers for Date Coding and Marking in the Dairy Industry?

The KEYENCE MK-G Series CIJ printers benefit dairy date coding with minimal maintenance and downtime, excellent traceability, regulatory compliance, and high-speed accuracy.

How Does KEYENCE's Continuous Inkjet Printer Contribute to Reducing Downtime and Increasing Productivity in Dairy Manufacturing?

KEYENCE’s CIJs feature constant breakpoint monitoring, a recycling conditioning tank to buffer or migrate ink dilution issues in cold environments, self-troubleshooting, one-touch nozzle replacement, and free printer monitoring network connectivity for uninterrupted production.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)