Continuous Inkjet Printers / Case Coder

Coding on Candy and Confectionery Packaging

Candy packaging presents key challenges for date coding on candy and confectionery products, like managing various package types, shapes, sizes, and materials. This makes consistent code application difficult.

The KEYENCE MK-G Series of continuous inkjet printers offer non-contact printing for high-speed packaging lines. With a compact design and self-troubleshooting capabilities, it is an ideal solution for coding on candy and confectionery packaging.

Lot Coding and Marking on Candy and Confectionery

Cartons

Paperboard Boxes

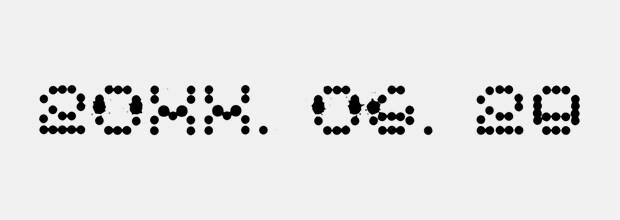

Paperboard boxes are popular for packaging candy, but traditional date coding on candy and confectionery product methods often cause smudged codes. MK-G Series continuous inkjet printers use advanced sensors and self-troubleshooting to ensure accurate, smudge-free coding.

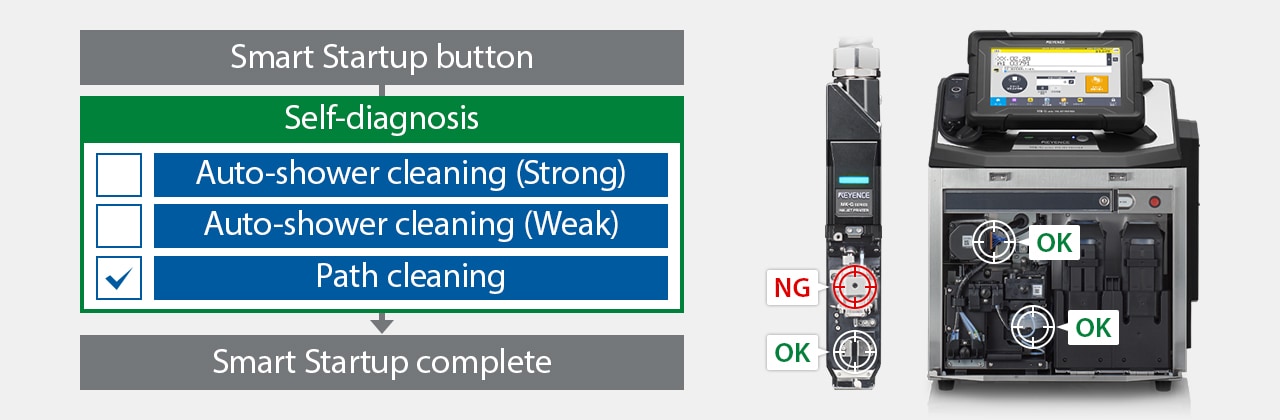

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

Pouches

Pouches

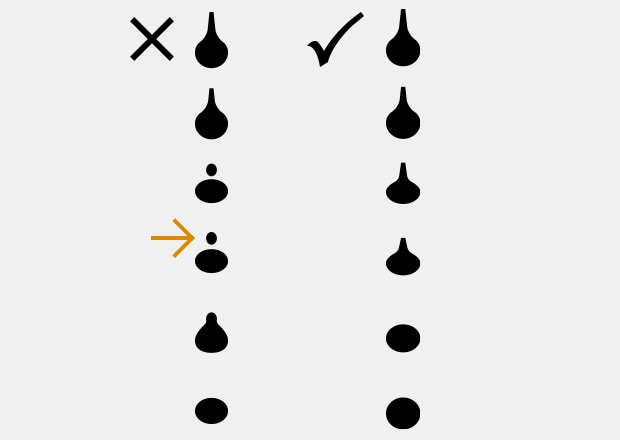

Pouches offer flexibility/design versatility, but coding them is challenging due to varying sizes/materials. The MK-G Series has automatic ink particle optimization for clear coding on any pouch.

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

KEYENCE Advantages

Automatic ink particle optimization:

The MK-G Series senses the ink particles 10 times per second, so it can automatically adjust itself to maintain optimum ink particle conditions. Stable printing is ensured by suppressing the impact of temperature fluctuations.

Less-than-optimal state of particles

Optimal particle state

Bags

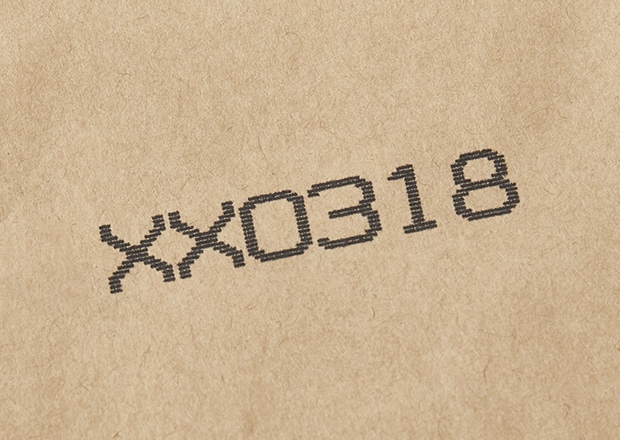

Multiple pre-printed bag variations increase costs and complicate inventory. CIJs for the food and beverage industry print barcodes, logos, and product information directly on bags, eliminating pre-printed designs.

Bags

Installation example

Flow Wrappers

Flow wrappers' high speed makes traditional coding inconsistent and illegible. MK-G Series ensures accurate coding with dynamic print control, intelligent print head positioning, and accurate print interval configuration.

Film packaging

Installation example

We’re here to provide you with more details.

Reach out today!

Challenges in Date Coding on Candy and Confectionery Products

High-Speed Production Lines

With rising demand, manufacturers seek faster production. Industrial inkjet printers are designed for high-speed lines, printing codes at an average of 300 meters (1143′) per minute.

Variety of Product Shapes and Sizes

Unlike traditional packaging, candies have irregular shapes, making consistent print quality difficult. The MK-G Series uses high-speed, non-contact inkjet printing to accurately print on any surface.

Glass containers

Heat-sealed packages

Bottle labels

Difficult Operating Environments

A major challenge in coding on candy and confectionery is harsh environments like extreme temperatures and humidity. The KEYENCE MK-G Series, with its IP55-rated head and controller, ensures reliable coding in these conditions.

Food Safety Regulations

Accurate coding on candy and confectionery is vital for compliance and product tracking in candy manufacturing. CIJ printers ensure clear codes on small packaging, maintaining food safety and efficiency.

Discover more about this product.

Click here to book your demo.

CIJ for Candy and Confectionery Packaging

When it comes to candy and confectionery packaging, KEYENCE CIJs integrate seamlessly into existing production lines, making them a popular choice for packaging facilities. KEYENCE CIJs are also designed to handle fast-paced and high-volume production environments, operating for long periods with minimal maintenance.

Curious about our pricing?

Click here to find out more.

FAQs about Date Coding in the Candy and Confectionery Industry

What Are the Regulatory Requirements for Date Coding on Candy and Confectionery Packaging?

Regulatory requirements for candy and confectionery products' date coding on candy packaging vary. The FDA mandates a clear expiration or "best if used by" date on all candy.

Can CIJ Date Coding Solutions Handle the Unique Packaging Materials and Shapes Often Found in the Candy and Confectionery Industry?

The KEYENCE MK-G Series provides reliable, non-contact printing, making it suitable for various packaging materials.

How Does Accurate Lot/Date Coding Help in Managing Inventory and Reducing Waste for Candy and Confectionery Manufacturers?

Precise candy and confectionery product date coding allows manufacturers to track shelf life and manage inventory, helping to avoid overproduction and potential waste.

What Are the Key Considerations When Selecting a Coding and Marking Solution for Candy and Confectionery Production Lines?

There are several key considerations to keep in mind like product packaging, maintenance, production speed, ink type, traceability requirements, and ease of integration.

How Do Date Coding Solutions Contribute to Counterfeit Prevention for Candy and Confectionery Manufacturers?

Marking production and expiration dates on products helps consumers verify authenticity, protecting brand reputation and preventing sales loss from counterfeits.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)