Coding for the Beverage Industry

In the beverage industry, efficient production and accurate coding is crucial. With lines running over 1,200 cans or bottles per minute, CIJs deliver fast, accurate coding without compromising print quality.

KEYENCE CIJs are an efficient and durable lot coding and date coding solution for the beverage industry, easily marking on a wide variety of materials like glass, plastic, and aluminum cans with manufacturing dates, lot numbers, and safety codes.

Date Coding and Marking on Beverages

Bottles

Bottles come in various shapes, sizes, and materials to meet manufacturers' needs. Continuous inkjet printers provide precise printing to code and mark bottles accurately. CIJ printers ensure clear, readable codes, meeting industry standards.

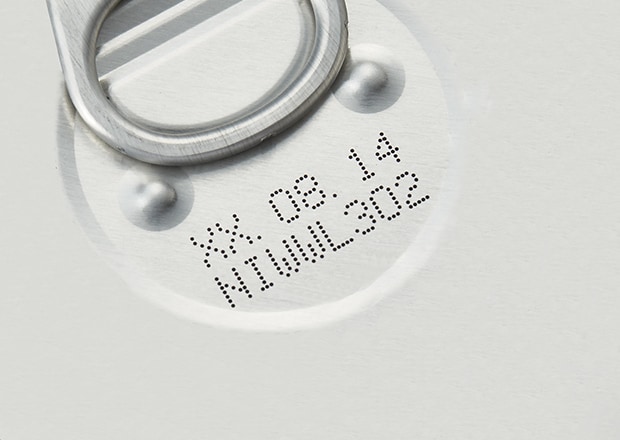

Printing example

Installation example

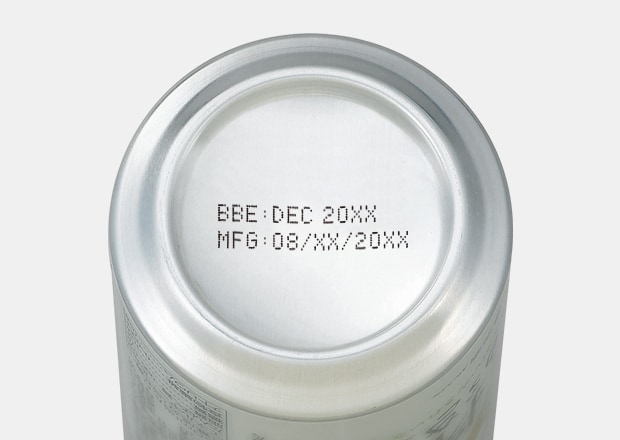

Cans

Cans are popular for beverages, especially carbonated drinks. Industrial inkjet printers ensure high-quality, legible codes on metal cans, even in harsh environments. One-touch nozzle replacement for immediate error recovery, minimizing downtime and ensuring efficient production.

Printing example

Installation example

Printing example

Installation example

Glass Bottles

Proper labeling on glass bottles is crucial. The MK-G Series' impact-resistant design can withstand any falls/impact during glass bottle marking. It also offers reliable, uninterrupted lot coding/date coding for clear/accurate labeling.

Printing example

Installation example

Hard Plastic Containers

Hard plastic containers are widely used in the beverage industry, making accurate beverage date coding essential. CIJ technology offers self-troubleshooting for quick issue resolution and easy maintenance/cleaning.

Printing example

Installation example

We’re here to provide you with more details.

Reach out today!

Challenges in Can and Bottle Coding in the Beverage Industry

- High-Speed Production

For beverages, high-speed production lines need efficient coding. Traditional inkjet printers cause downtime and reduce productivity. KEYENCE CIJs offer automatic maintenance, troubleshooting, and quick nozzle replacement, maximizing uptime. - Environmental Factors

Beverage cans and bottles encounter moisture, condensation, and extreme temperatures affecting beverage date coding and labeling. The MK-G Series excels in harsh conditions with IP and MIL drop ratings on the controller and print head, ensuring dust and moisture resistance. - Harsh Cleaning Procedures

Sanitation is rigorous to prevent health risks. This washdown can pose a hazard to complex electrical equipment like CIJ. This is why the MK-G Series was designed with an IP-rated print head. Automated print head cleanings also alleviate the need to open the print head up and expose it to the countless liquid hazards in the beverage industry.

Curious about our pricing?

Click here to find out more.

CIJ Coder for Beverages

With various packaging materials and surfaces, it can be challenging to achieve consistent beverage date coding quality while maintaining high production uptime. CIJs are designed to easily adapt to different types of packaging materials and surfaces, making them an ideal solution for beverage manufacturers.

One of the biggest advantages is its ability to increase uptime with minimal maintenance. This means less downtime for manual adjustments or repairs, allowing for continuous production without interruption.

Discover more about this product.

Click here to book your demo.

FAQs about Date Coding on Cans and bottles in the Beverage Industry

What Are the Benefits of Implementing KEYENCE Date Coding CIJ Technology in the Beverage Industry?

The benefits include compliance with regulations, no compromise on accuracy for speed, traceability and product safety, and minimal maintenance requirements and downtime.

How Does KEYENCE's CIJ Technology Cater to the Specific High Demands of Coding on Cans and Bottles?

One main advantage is its ability to deliver fast, accurate beverage coding and marking without compromising print quality. The built-in diagnostics of KEYENCE CIJ systems ensure consistent performance and prevent beverage coding errors, minimizing downtime and reducing waste.

How Does CIJ Help Manufacturers Comply with Regulatory Requirements and Industry Standards for Date Coding on Beverages?

CIJ printers provide high-speed, reliable performance for printing batch numbers, expiry dates, and other crucial info. They ensure traceability in production, aiding quality control and compliance with safety regulations.

Can MK-G Series Coders Seamlessly Integrate into Existing Beverage Production Lines for Tracking and Traceability?

They are compact, easily adaptable, and simple to install in your production setup. Since MK-G Series coders require no skilled labor and less human interaction, resulting in less user error, they offer a cost-effective beverage coding and marking solution.

Why Is Date Coding on Cans and Bottles Critical for Product Traceability and Recall Management?

Beverage date coding enables manufacturers to consistently track products through the supply chain with high quality codes and can swiftly identify affected batches during a recall.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)