Coding on Baked Goods Packaging

In the food industry, coding on baked goods is a necessity for traceability and compliance purposes. Manual data entry, clear coding on various packaging materials, and maintenance are common challenges. The KEYENCE MK-G Series printers streamline this process, offering high-speed, reliable printing to enhance operational efficiency.

Date Coding and Marking on Baked Goods Packaging

Cardboard

The MK-G Series prints precise, high-quality best-by dates and lot numbers on bread boxes and pastry cartons with ease.

Cartons

Cardbord boxes

Plastic Bags, Film, and Foil Pouches

Marking on such materials that hold baked goods can be costly. The MK-G CIJ can print on uneven surfaces without compromising ink adhesion while maintaining print accuracy.

Form-filled packages

Pouches

Aluminum puches

Paperboard

The MK-G Series efficiently marks with high speed and quality to ensure durable baked goods coding for this material, including paperboard sleeves.

Packing film

Bags

Wrappers and Clamshells

The MK-G Series excels at higher throughput and high-quality coding on containers used for pastries and other baked goods.

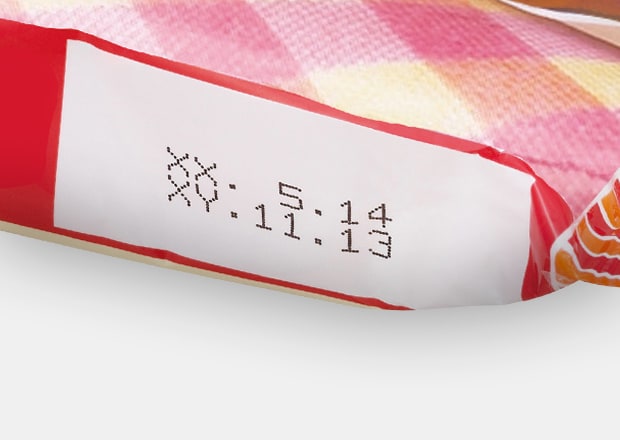

Printing example

Installation example

Kwik Locks

Printing example

Kwik Lock closures, such as the plastic tags used to seal bread bags, are reliably marked with non-contact printing by the MK-G Series, ensuring clear codes on small surfaces.

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Baked Good Packaging

Diverse Packaging Materials

Coding on baked goods with different packaging materials can be challenging due to variations in surface texture, material composition, and the need for consistent print clarity.

Product Knowledge and Skills

Training technicians on new products can be time consuming, especially with a lack of skilled labor available to meet operational demands.

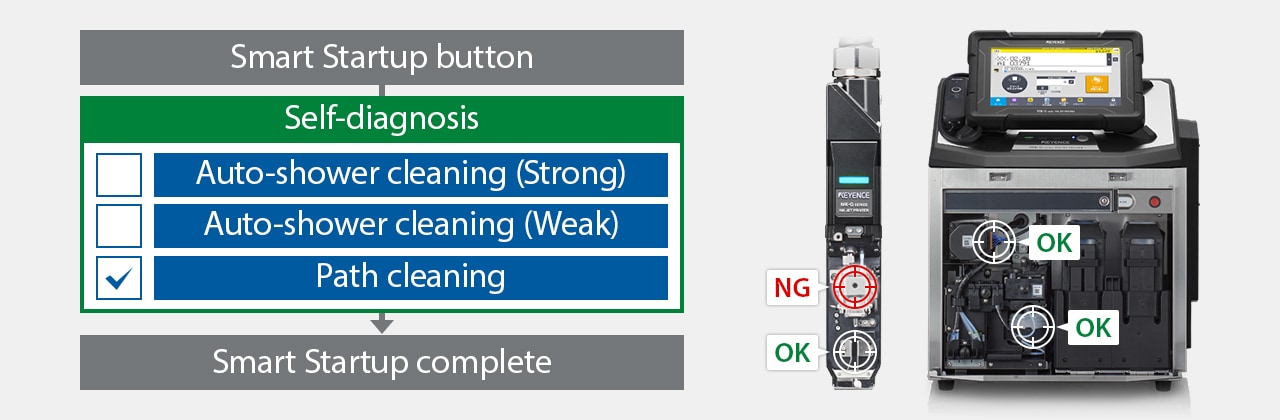

Maintenance and Troubleshooting

Repairs, maintenance, and troubleshooting are often costly and require significant resources to address and resolve.

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

Curious about our pricing?

Click here to find out more.

CIJ for Baked Goods Industry

The KEYENCE MK-G Series features exceptional print quality, a user-friendly interface, automatic troubleshooting, and reliable performance. Its intuitive design reduces training requirements, making it easy for operators to code on packaging with minimal effort. These benefits ensure operations run efficiently and that consistent, high-quality marks are achieved.

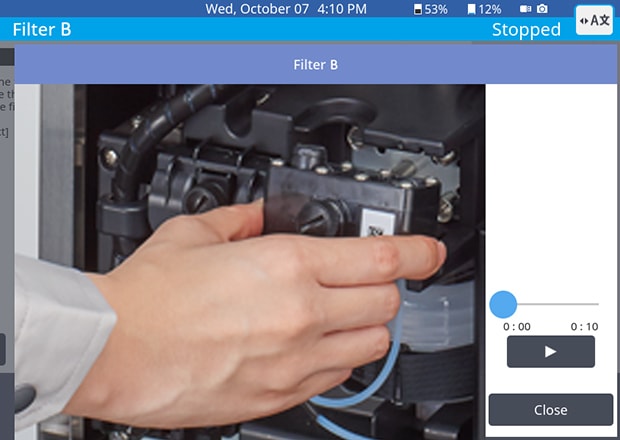

Simply follow the instructional video for error-free replacement.

Access Helpful Component Replacement Instructional Videos

When replacing a component, simply read the barcode or 2D code on the component to watch a helpful instructional video. These easy-to-follow videos make replacement simple even for beginners.

Discover more about this product.

Click here to book your demo.

FAQs about Coding in Baked Goods Packaging

Can These CIJ Coding Systems Accommodate High-Speed Production Lines for the Baked Goods Industry?

Yes, the MK-G Series continuous inkjet printers accommodate high-speed production lines by seamlessly integrating into existing setups without compromising print quality and offering quick changeovers to minimize downtime.

How Do Coding Solutions Help Minimize Product Waste and Maximize Production Efficiency in the Baked Goods Industry?

Code legibility is essential to limit the chance of rework and traceability issues. Automated coding solutions reduce errors that can result in recalls, wasted storage, and products. The MK-G Series coding system enhances these benefits with its self-cleaning functionality, advanced monitoring capabilities, and automatic ink particle optimization, which help it work in varying conditions and temperatures.

What Are the Advantages of Using Continuous Inkjet Printers over other Types of Printers for Date Coding on Baked Goods Packaging?

MK-G Series industrial inkjet printers offer versatility in printing on various materials, such as films, foils, and plastics for bulk packaging or single serve, simple integration, high-speed performance with durable markings, minimal training and downtime, and easy maintenance.

How Do Marking and Coding Solutions Handle Dusty/Powdery Environments Typical in Some Baked Goods Production Processes?

The MK-G Series with an IP55 rating for both the controller and print head ensures durability in the harshest of environments. Clear codes remain legible throughout the product's shelf life, which is why marking and coding solutions are essential for CIJs in the food and beverage industry.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.