Data Acquisition (DAQ)

What is a Test Bench?

-

Tags:

- Data Acquisition

A test bench, also known as a test bed or test stand, is a controlled environment used to evaluate a product. It replicates real-world conditions that allow engineers to test devices and evaluate their performance in specific repeatable scenarios.

Test benches can be physical or virtual. A physical test bench is an environment that replicates real-world conditions, allowing engineers to test devices in specific and controlled conditions. Virtual test benches do the same but for software. Both help to ensure that products meet quality standards and perform as intended before they reach the consumer.

Types of Test Benches

The type of test bench is entirely dependent on the product and the end objective. Whether physical or virtual, test benches come in different forms. The following are some of the types of test benches:

- 1. Simulation Test Benches

- These test benches use software models to mimic real-world conditions and operational scenarios. Simulations create models to help predict how a product will behave. They are ideal for testing products where a physical test would be impractical. Typically, these are used in early stage design and development for complex electronic systems and software.

- 2. Emulation Test Benches

- These test benches replicate hardware to test how software will function in an emulated environment. These are particularly helpful if the hardware is costly to produce or not yet fully available. With an emulated environment, testing can begin before the final product has left production.

- 3. End-of-Line (EoL) Test Benches

- Commonly found at the end of a production cycle, an EoL test bench is used primarily for quality assurance and is the last step before the product goes out the door. It is here that any final bugs or flaws can be identified.

- 4. Accelerated Test Benches

- To make sure a product will hold up over time, accelerated test benches are used to simulate periods of extended stress to test the durability and performance of the end product.

We’re here to provide you with more details.

Reach out today!

Applications of Test Benches in Different Industries

Regardless of industry, bench testing is a constant process in production. Ongoing testing ensures that a product meets requirements and that it can withstand real-world applications.

In the automotive industry, bench testing is used to verify vehicle safety and environmental compliance. Engine bench testing evaluates the performance and durability of an internal combustion system by deploying dynamometers and exhaust analyzers to measure emissions. Similarly, simulations are run on the chassis to test how a vehicle will handle and perform out on the road.

The aerospace sector also relies heavily on testing to keep its systems and components up to par. Many of these tests are done to ensure durability and to keep planes in the air. Environmental tests are done to simulate harsh climates and intense temperature changes. Structural tests are performed to test the integrity of the wings and fuselages, while avionics tests the communication and navigation systems that will be onboard.

Furthermore, in electronics and hardware development, digital logic test benches are used to validate the functionality of circuits and components. They test using simulation tools and waveform viewers to analyze different input behaviors. These products also undergo environmental testing and are monitored for how well they can handle heat and vibrations.

Bench testing isn’t limited to the industries listed above either. They are present at every step of the production process. Manufacturers and engineers are able to push the limits and simulate possible outcomes that meet the demands of their consumers.

Benefits of Using a Test Bench

Having the ability to simulate real-world scenarios and obstacles during production reduces the risk of costly recalls later. Early detection prevents issues from escalating into large-scale production failures. Bench testing also reveals weaknesses and areas for possible improvement during the developmental stages. In turn, manufacturers can produce a more refined and higher quality product.

Beyond that, test benches keep products in line with regulatory compliance and long-term safety. Many industries have rigorous standards they have to meet, such as the CE and UL certifications. Test benches also reduce the financial and personnel risk taken by live testing products. This is especially important in aerospace and defense operations where the risks to human life can be extremely high.

Discover more about this product.

Click here to book your demo.

How to Design an Effective Test Bench

There is no universal test bench design that will be effective across the board. Every industry has its own parameters and testing objectives, and each bench will be built to those specifications. However, there are certain components that each test bench should include in some capacity to operate effectively. Features of a good test bench include:

- Actuators: Simulate real-world forces or movements, such as hydraulic cylinders, electric motors, or pneumatic actuators.

- Sensors: Measure physical parameters like temperature, pressure, strain, or flow.

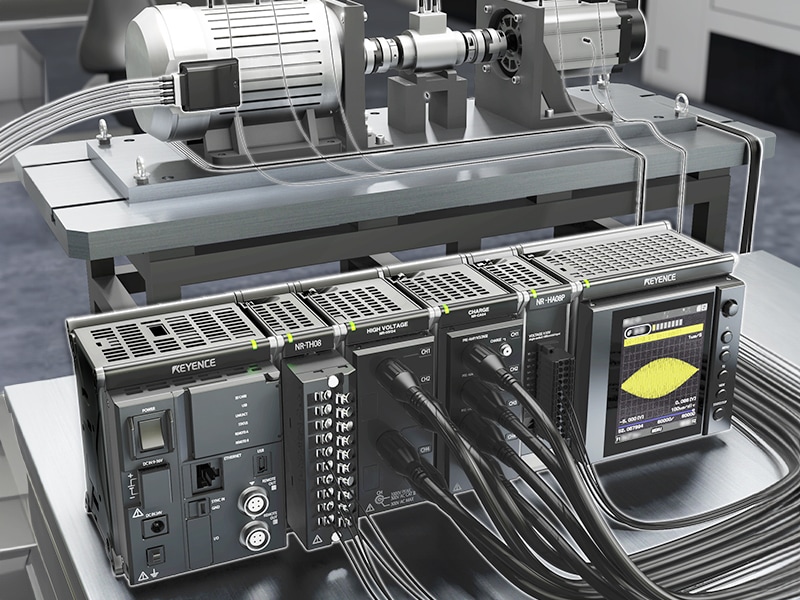

- Data Acquisition (DAQ) Systems: Collect and process data in real-time, enabling synchronized analysis of test results.

- Controllers: Manage and regulate test bench operations using programmable logic controllers (PLCs) or microcontrollers.

- Simulation Software: Mimics real-world conditions to create controlled testing scenarios for electronics and software systems.

- Automation Tools: Streamline repetitive testing tasks, improving efficiency and consistency.

- Environmental Control Systems: Maintain desired operating conditions, such as temperature or humidity, for specific testing needs.

Challenges and Considerations in Test Bench Usage

Bench testing doesn’t come without its own set of challenges. One of the more prevalent issues is how bench testers will integrate their hardware and software. Compatibility and scalability are two features that have to be taken into consideration to stay ahead in these ever-growing industries.

Another challenge is the large volumes of data generated during testing. Without the ability to effectively collect, store, and analyze data, engineers cannot gain insights into the results of their tests. A solution to that is data loggers, like the NR-X Series produced by KEYENCE, which allow for the real-time capture and organization of data. These data loggers are small and lightweight, with the NR-500 Series measuring 20.5 mm 0.81″ wide and weighing just 110 g 3.88 oz in design, which means they are practical for even the smallest of work areas.

Get detailed information on our products by downloading our catalog.

View Catalog

Emerging Trends and Advancements in Test Bench Technology

Technology is constantly advancing, and test benches are evolving along with it. A trend many bench testers are implementing is automation in specific tests. Reducing the chance of human error and allowing tests to be completed with more precision. Virtualization, either through emulation or simulation, has proven itself in helping engineers create incredibly realistic real-world conditions without having a need for physical prototypes. There is also a huge push to make sustainability a priority and produce energy-efficient components that minimize environmental impact.

There will never be a world where bench testing isn’t required. No matter the industry, be it automotive or electronics—test benches create the controlled environments essential for ensuring innovation and meeting compliance standards. With its ability to be customized across industries, manufacturers can be sure every product is tested thoroughly before it reaches the consumer.

If you’re ready to plan out your next test bench or just need to replace your old data logger, reach out to KEYENCE today. We can help you bring your testing capabilities into the future.